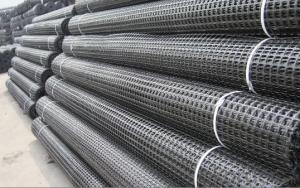

Tenax High Strength Biaxial Geogrids - Manufactured PP

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction of PP/HDPE Biaxial Geogrid:

Uniaxial geogrid, made of high molecular polymer, is extruded into sheet and then punched into regular mesh pattern, and finally stretched in the longitudinal direction.

Features of PP/HDPE Biaxial Geogrid:

With high tensile strength and tensile modulus

Application of PP/HDPE Biaxial Geogrid:

Mainly applied in highway, railway, slope protecting projects, retaining wall, dam etc.

1)strengthen land loading capacity and extend its service life.

2) convenient to construct ; reducing area , project cost and maintenance cost.

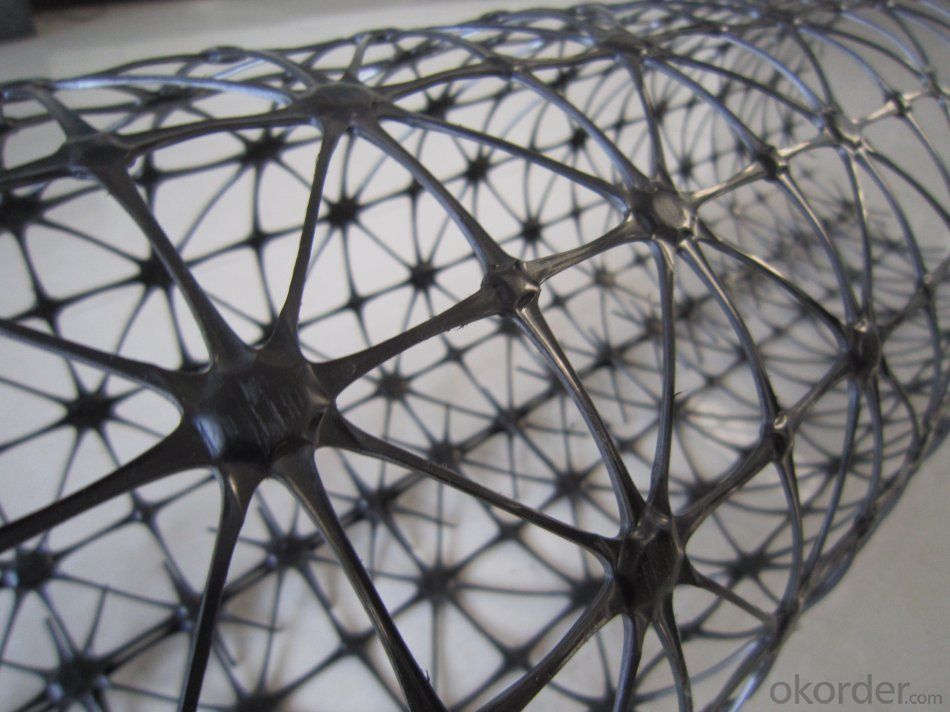

Features of PP Biaxial Geogrid:

1. With high tensile strength in longitudinal and transversedirections

2.This structure can provide an chain system of more effective force bearing and spreading for the soil.

Application of PP Biaxial Geogrid:

Mainly applied in highway, railway, slope protecting projects etc.

1)strengthen land loading capacity and extend its service life.

2) convenient to construct ; reducing project cost and maintenance cost.

Features of Polyester Geogrid:

1) High tensile strength

2) High tear-resistant

3) Strong combination with gravel and soil

Application of Polyester Geogrid:

It mainly applied in strengthening soft ground of rail and road.

FAQ:

Q1: What is your minimum order quantity?

A:The minimum order quantity is 5000 ,but it is negotiable.

Q2:What is your payment terms?

A: T/T,Western Union,Paypal,L/C...

Q3:What is your delivery time?

A:Production time usually costs 2-20 days.

Waiting to cooperate with you!

- Q: Can geogrids be used in reinforcement of geosynthetic clay liners?

- Yes, geogrids can be used in the reinforcement of geosynthetic clay liners. Geogrids are commonly used to enhance the tensile strength and stability of geosynthetic clay liners, thereby improving their performance in various applications such as landfill liners, pond liners, and slope stabilization. The geogrids are typically placed between layers of geosynthetic clay liners to provide additional reinforcement and prevent potential failure modes such as lateral sliding and slope instability.

- Q: Are geogrids suitable for reinforcing bridge abutment backfills?

- Yes, geogrids are suitable for reinforcing bridge abutment backfills. Geogrids are commonly used in civil engineering and construction projects to enhance the stability and strength of soil structures. They can effectively distribute loads, reduce soil settlement, and improve overall performance of backfill materials. Therefore, geogrids are a reliable option for reinforcing bridge abutment backfills.

- Q: How do geogrids improve the performance of geosynthetic reinforced slopes?

- Geogrids improve the performance of geosynthetic reinforced slopes by providing reinforcement and stability to the soil. They enhance the tensile strength of the soil, preventing it from sliding or collapsing. Geogrids also distribute the load evenly across the slope, reducing stress concentrations and promoting better load-bearing capacity. Additionally, they facilitate better interlocking between soil particles, increasing the overall shear strength and resistance to erosion.

- Q: Do geogrids require maintenance?

- Yes, geogrids do require maintenance. Routine inspection is necessary to ensure their proper functioning and longevity. This may involve checking for any signs of damage, such as tears or punctures, and addressing any issues promptly. Additionally, regular cleaning and removal of debris is important to prevent clogging and maintain the effectiveness of geogrids. Overall, proper maintenance helps to extend the lifespan and performance of geogrids in various applications.

- Q: How do geogrids improve the stability of cut slopes?

- Geogrids improve the stability of cut slopes by providing reinforcement to the soil, preventing it from sliding or slumping. These grid-like structures are placed within the soil layers, distributing the forces exerted by the slope and increasing its overall strength. Additionally, geogrids enhance the soil's ability to withstand erosion, maintain its integrity, and prevent the formation of cracks.

- Q: How do geogrids improve the performance of retaining walls in earthquake-prone areas?

- Geogrids improve the performance of retaining walls in earthquake-prone areas by providing reinforcement and stability. These high-strength geosynthetic materials are placed within the soil behind the retaining wall, which helps to distribute the forces generated during an earthquake more evenly. This reduces the pressure on the wall and enhances its resistance to lateral movement and potential failure. Geogrids also increase the overall strength and load-bearing capacity of the soil, making the retaining wall more resilient against seismic forces.

- Q: How do geogrids improve pavement performance?

- Geogrids improve pavement performance by enhancing the structural integrity of the pavement layers. They distribute the load and stress more evenly, reducing cracking and rutting. Geogrids also prevent the lateral movement of soils, which helps to maintain the stability of the pavement and reduces maintenance costs in the long run.

- Q: What are the environmental impacts of using geogrids?

- The environmental impacts of using geogrids can vary depending on factors such as their production, installation, and disposal. However, in general, geogrids can have positive environmental impacts. They can help stabilize soil and reduce erosion, which can prevent the loss of topsoil and decrease sedimentation in nearby bodies of water. Geogrids can also be made from recycled materials, reducing the demand for virgin resources. However, the use of geogrids may also have some negative impacts, such as the energy consumption and greenhouse gas emissions associated with their production and transportation. Additionally, if not properly disposed of, geogrids can contribute to plastic pollution. Overall, while geogrids offer numerous environmental benefits, it is important to consider their life cycle and proper disposal to minimize potential negative impacts.

- Q: What is the road geogrid

- Classified editingPlasticAfter stretching form a square or rectangular net polymer material, according to the manufacture of the tensile direction for different uniaxial tension and biaxial tension. It is two in the polymer sheet by extrusion (the raw material is polypropylene or high-density polyethylene) on the hole, and then the implementation of directional tension in the heating conditions. Tension only along the length direction grid sheet tension; biaxial stretching grille is to continue the grille of one-way drawing again with its length in the direction perpendicular to the tensile material.Because of the polymer plastic geogrid in the manufacture of polymers with heating process and rearrange the directional extension, strengthen the contact force between molecular chains, to improve its strength. The elongation rate of only 10% to 15%. if the original sheet in geogrid with carbon black and ageing resistant material, can make it has good acid and alkali resistance, corrosion resistance and ageing resistance and durability.

- Q: What are the standards for geogrid testing and certification?

- The standards for geogrid testing and certification typically include various parameters such as tensile strength, junction strength, aperture size, creep behavior, and durability. These tests are conducted according to industry-recognized standards such as ASTM D6637, ISO 10319, and GRI-GG2. The certification process ensures that geogrids meet the required performance criteria and can be used effectively in geotechnical applications.

Send your message to us

Tenax High Strength Biaxial Geogrids - Manufactured PP

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords