Geocells Suppliers - Composite Drainage Geogrid and Geotextile Compound

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 2000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of Geogrid:

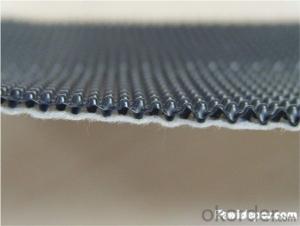

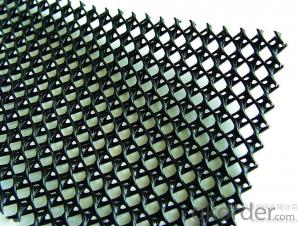

Composite geogrid is geogrid and geotextile compound, organic combine the geogrid and geotextile both good performance. Is a new type of geosynthetics.

Product features: it has high tensile strength, elongation is small, the characteristics of vertical and horizontal deformation uniformity. At the same time with high permeability, the filter resistance and abrasion resistance good.

Main function: road, subgrade strengthening, inverse filter, drainage, protection, isolation.

Application: 1, used in highway, railway, airport pavement enhancement. 2, used in the old pavement (asphalt pavement, cement concrete pavement maintenance, widen, etc. 3, used for subgrade enhancement.

Applications of Geogrid:

Make reinforce treatment for various kinds of soft soil foundation to evenly distribute load stress and reduce uneven settlement, not easy to generate static electricity, and flammability property good in the coal mine. It is easy to wash coal.

Used in highway, railway, port, airport and municipal project. Support in the recovery working face of coal mine and roadway in the coal mine.

Index Properties | Test Method | Unit | GG1515 | GG2020 | GG3030 | GG4040 |

MD TD | MD TD | MD TD | MD TD | |||

Polymer | -- | -- | PP | PP | PP | PP |

Minimum Carbon Black | ASTM D 4218 | % | 2 | 2 | 2 | 2 |

Tensile Strength@ 2% Strain | ASTM D 6637 | Kn/m | 5 5 | 7 7 | 10.5 10.5 | 14 14 |

Tensile Strength@ 5% Strain | ASTM D 6637 | Kn/m | 7 7 | 14 14 | 21 21 | 28 28 |

Ultimate Tensile Strength | ASTM D 6637 | Kn/m | 15 15 | 20 20 | 30 30 | 40 40 |

Strain @ Ultimate Strength | ASTM D 6637 | % | 13 10 | 13 10 | 13 10 | 13 10 |

Structural Integrity | ||||||

Junction Efficiency | GRI GG2 | % | 93 | 93 | 93 | 93 |

Flexural Rigidity | ASTM D 1388 | Mg-cm | 700000 | 1000000 | 3500000 | 10000000 |

Aperture Stability | COE Method | mm-N/deg | 646 | 707 | 1432 | 2104 |

Dimensions | ||||||

Roll Width | -- | M | 3.95 | 3.95 | 3.95 | 3.95 |

Roll Length | -- | M | 50 | 50 | 50 | 50 |

Roll Weight | -- | Kg | 39 | 50 | 72 | 105 |

MD denotes Machine direction. TD denotes transverse direction. | ||||||

Property of Geogrid:

1.) Improve roadbed bearing capacity,enlarge road lifetime.

2.) Prevent road collapse and crack

3.) Prevent soil and water loss in slope

4.) Could replace steel-plastic geogrid in coal mine.

| Packaging Details: | PE film |

| Delivery Detail: | within 10 days after contract is effective |

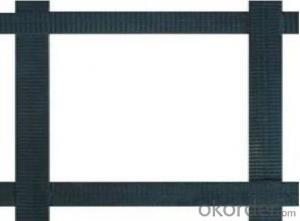

Geogrid Show:

FAQ:

1. How to order your geogrid ?

a). Tensile strength in warp & weft direction

b). Grid size

c). Width and length

d). Quantity

2. Payment term .

a) TT

b) LC AT SIGHT

c) cash

d) 30% contact value as deposit ,the blance 70% be paid after received the copy of bl .

3. Delivery time

a) 19-25 days after received your depsit .

4. What is MQQ ?

a) 2500 m2 as MQQ , we can also produce sample for you .

- Q: What are the long-term performance monitoring requirements for geogrids?

- The long-term performance monitoring requirements for geogrids include regular inspections, assessment of durability and strength retention, measurement of creep and relaxation behavior, evaluation of long-term deformation and stability, and monitoring of the geogrid-soil interaction. Additionally, it is vital to monitor any potential degradation from environmental factors such as UV exposure, chemical exposure, and biological activity to ensure the geogrid's effectiveness over time.

- Q: What is the effect of geogrid aperture size on performance?

- The effect of geogrid aperture size on performance is that a smaller aperture size generally leads to better performance. This is because a smaller aperture size allows for better soil confinement and interlocking, resulting in improved stability, load distribution, and overall performance of the geogrid. A larger aperture size, on the other hand, may lead to reduced confinement and interlocking, potentially compromising the geogrid's performance.

- Q: How do geogrids improve the performance of geotechnical structures?

- Geogrids improve the performance of geotechnical structures by enhancing their stability, reducing soil erosion, and increasing load-bearing capacity. They provide reinforcement and confinement to the soil, preventing lateral movement and improving overall structural integrity. Additionally, geogrids distribute loads more evenly, reducing the risk of settlement and improving long-term durability of the structures.

- Q: Is it possible to add fiberglass grille between asphalt pavement and asphalt pavement

- First look at the drawing design requirements

- Q: How do geogrids improve the performance of bridge abutments?

- Geogrids improve the performance of bridge abutments by providing additional stability and reinforcement to the soil. They distribute the loads more evenly, prevent soil erosion, and increase the overall strength of the structure.

- Q: Can geogrids be used in reinforcement of underground utility corridors?

- Yes, geogrids can be used in the reinforcement of underground utility corridors. Geogrids are commonly used in civil engineering applications to provide strength and stability to soil, including underground structures such as utility corridors. They are effective in distributing load and preventing soil movement, enhancing the overall performance and durability of the underground utility corridors.

- Q: Can geogrids be used in ground stabilization for pipelines?

- Yes, geogrids can be used in ground stabilization for pipelines. Geogrids are commonly used in pipeline construction to reinforce the soil and prevent lateral movement or settlement. They provide additional support and stability to the ground, ensuring the pipeline remains in place and minimizes the risk of damage or failure.

- Q: Are geogrids suitable for use in steep slopes?

- Yes, geogrids are suitable for use in steep slopes. They provide reinforcement and stability to the soil, reducing the risk of erosion and landslides. Geogrids are designed to distribute loads and improve the overall strength of the slope, making them an effective solution for steep terrain.

- Q: How do geogrids enhance the stability of steep railway cuttings?

- Geogrids enhance the stability of steep railway cuttings by providing reinforcement and increased tensile strength to the soil. These materials are placed within the soil to create a network of interconnected elements, which distribute and transfer loads more efficiently. This helps to resist the lateral forces exerted by the soil, preventing slope failure and maintaining the integrity of the railway cutting.

- Q: How do geogrids help in reducing the need for excavation and replacement of poor soils?

- Geogrids help in reducing the need for excavation and replacement of poor soils by providing reinforcement and stabilization to the soil, improving its load-bearing capacity. This prevents excessive settlement and movement of the soil, reducing the need for costly excavation and replacement.

Send your message to us

Geocells Suppliers - Composite Drainage Geogrid and Geotextile Compound

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 2000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords