Tenax Uniaxial Geogrids Fiberglass with Non-Woven Production Line

- Loading Port:

- Qingdao

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

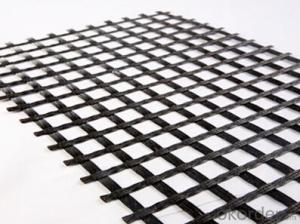

Fibergalss Geogrid Profile

Fiberglass geogrid is a new excellent maeterial used for reinforcing road surface and base, it made by fiberglass filament, and covered by special solution. High longitudinal and horizontal strength, low elongation rate, anti-alkali and aging resistance, widely used in asphalt road surface, concrete road surface and reinforceing road base.

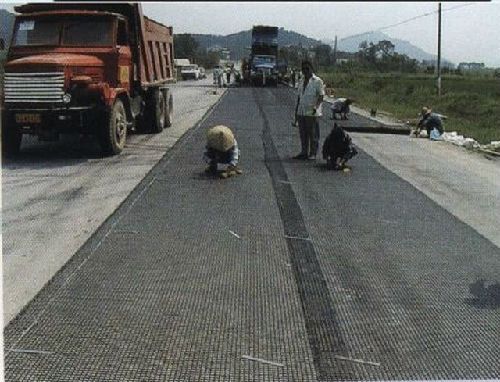

Main feature of Fiberglass Geogrid with Non Woven Production Line

Fiberglass geogrid is for asphalt road, highway, expressway, strengthen its intension

Main features as the following:

1. High intensity

2. Low elongation

3. Heating stability

4. Easily mixing with asphalt

5. Anti-high temperature

6. Anti-low temperature

Detail Specifications of Fiberglass Geogrid

Specification | 1×1 | 1×1 | 1×1 | 1×1 | 1×1 | 2×2 | 2×2 | |

Strength | Long . Horiz | ≥30 | ≥50 | ≥60 | ≥80 | ≥100 | ≥60 | ≥80 |

≥30 | ≥50 | ≥60 | ≥80 | ≥100 | ≥60 | ≥80 | ||

Percentage of Elongation | 4% | 4% | 4% | 4% | 4% | 4% | 4% | |

Size of Hole mm | 25.4×25.4 | 25.4×25.4 | 25.4×25.4 | 25.4×25.4 | 25.4×25.4 | 12.7×12.7 | 12.7×12.7 | |

Flexibility | 76 | 76 | 76 | 76 | 76 | 76 | 76 | |

Width M | 1--6 | 1--6 | 1--6 | 1--6 | 1--6 | 1--6 | 1--6 | |

Temperature | -100200 | -100200 | -100200 | -100200 | -100200 | -100200 | -100200 | |

FAQ

1. What's the usage of Polypropylene Biaxial geogrid?

It's used for reinforce the roadbeds in softe soil, railway, tunnel, slope and embankment etc. It has good performance on preventing the cracks.

2. How about your quality of Polypropylene Biaxial geogrid?

We have strict quality control system, we make testing on incoming raw material and finished products. Your third party testing is also welcomed. With high quality, our products are used on government projects at home and abroad. Our product quality is accepted by clients from all over the world.

Product Photos

- Q: How do geogrids enhance the stability of steep highway embankments?

- Geogrids enhance the stability of steep highway embankments by providing additional reinforcement and load-bearing capacity to the soil. They act as a strengthening layer, preventing soil erosion and reducing the risk of slope failure. Geogrids distribute the applied loads more evenly, improving the overall stability and preventing soil movement.

- Q: How do geogrids improve the performance of geogrid-reinforced earth walls?

- Geogrids improve the performance of geogrid-reinforced earth walls by providing reinforcement and stabilizing the soil. They distribute the tensile forces caused by the earth pressure more evenly, reducing the risk of wall failure and increasing overall stability. Additionally, geogrids help to limit soil movement, prevent erosion, and improve the long-term durability of the reinforced wall structure.

- Q: Geogrid tgsg45-45 what does it mean

- Hello ~TGSG is just a product code

- Q: Are geogrids suitable for reinforcing steep slopes?

- Yes, geogrids are suitable for reinforcing steep slopes. Geogrids are high-strength, flexible, and durable materials that can provide stability and prevent soil erosion on steep slopes. They enhance the soil's shear strength, distribute loads, and improve slope stability, making them an effective solution for reinforcing steep slopes.

- Q: How do geogrids help in reducing construction waste?

- Geogrids help in reducing construction waste by providing a stable base for construction materials, reducing the need for excessive excavation and fill. This minimizes the amount of waste generated during the construction process and saves resources by utilizing existing materials efficiently. Additionally, geogrids enhance the durability of structures, reducing the need for frequent repairs or replacements, which further reduces construction waste.

- Q: Can geogrids be used for reinforcement in embankments and dams?

- Yes, geogrids can be used for reinforcement in embankments and dams. Geogrids are a type of geosynthetic material that provide strength and stability to soil structures. They are commonly used in civil engineering projects to reinforce and stabilize embankments and dams, as they improve the overall structural integrity and prevent soil erosion.

- Q: How to read geogrid grilleBe careful not to copy the dictionary. I want to know why he read it hereI look at the dictionary said: the gate of zhBlock made of bamboo, iron bars, etc.. barsIs it because geogrid can also be seen as a strip of things, so read Zha

- And the glass fiber grid, but because of the large deformation of the plastic grille and glass fiber grille is mainly suitable for the cause of the road engineering, and the emergence of a new type of steel plastic composite geogrid

- Q: What are the factors to consider when selecting geogrids for a project?

- When selecting geogrids for a project, it is important to consider factors such as the site conditions, load requirements, and the desired application. The site conditions, including soil type, slope stability, and groundwater levels, will determine the type and strength of geogrid needed. Load requirements, such as traffic or equipment loads, will impact the geogrid's tensile strength and durability. Additionally, considering the desired application, such as soil stabilization, retaining walls, or erosion control, will help determine the appropriate geogrid material and design.

- Q: Can geogrids be used in reinforcement of retaining walls?

- Yes, geogrids can be used in the reinforcement of retaining walls. Geogrids are commonly used to enhance the stability and strength of retaining walls by providing additional reinforcement. They help distribute the forces exerted by the soil and improve the overall performance and longevity of the retaining wall structure.

- Q: What is the difference between uniaxial and biaxial geogrids?

- Uniaxial geogrids have strength and stiffness in one primary direction, typically in the machine direction. This means they provide reinforcement in one direction only. On the other hand, biaxial geogrids have strength and stiffness in both the machine direction and cross-machine direction, providing reinforcement in two perpendicular directions.

1. Manufacturer Overview

| Location | Shandong, China |

| Year Established | 2002 |

| Annual Output Value | Above US$ 20 Million |

| Main Markets | 20.00% North America 15.00% South America 15.00% Eastern Europe 10.00% Southeast Asia 10.00% Northern Europe 10.00% South Asia 10.00% Western Europe 5.00% Africa 5.00% Mid East |

| Company Certifications | ISO9001:2000; |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Qingdao Port |

| Export Percentage | 41% - 50% |

| No.of Employees in Trade Department | 6-10 People |

| Language Spoken: | English; Chinese; |

| b) Factory Information | |

| Factory Size: | Above 80,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | Design Service Offered; Buyer Label Offered |

| Product Price Range | High; Average |

Send your message to us

Tenax Uniaxial Geogrids Fiberglass with Non-Woven Production Line

- Loading Port:

- Qingdao

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords