High Tensile Galvanized PVC Coated Barbed Iron Wire for Security

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Description

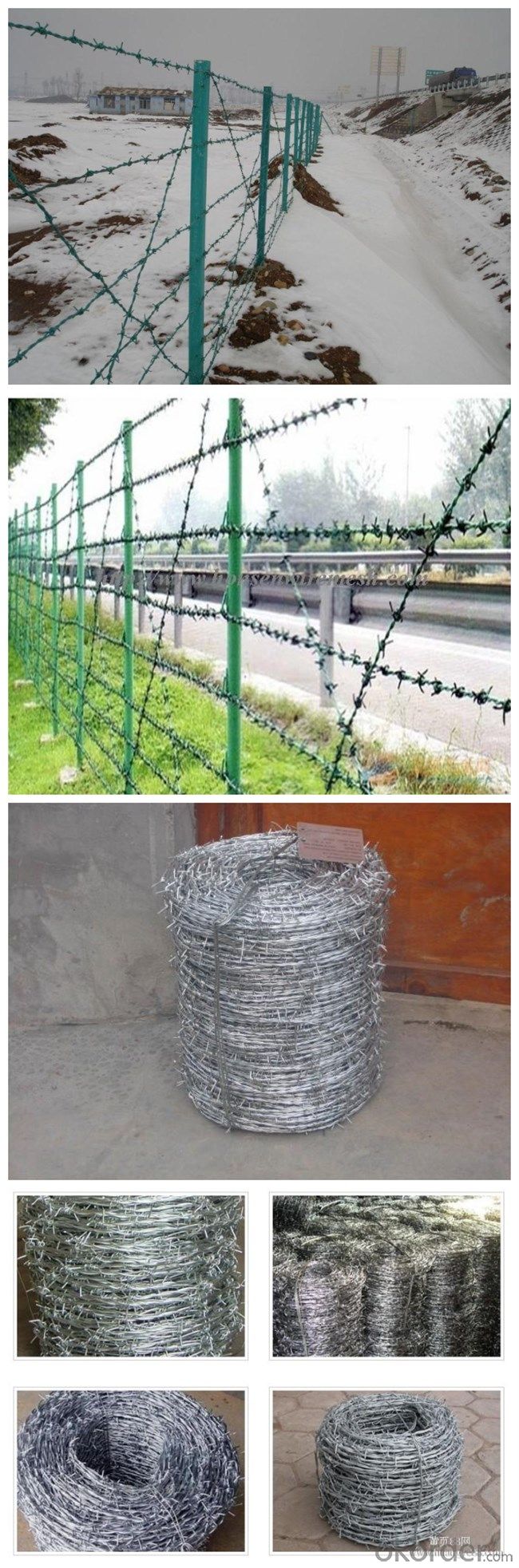

Barbed wire material: Galvanized steel wire, PVC coated steel wire in green, blue and other colors

Classification: Single twist barbed wire, double twist barbed wire, traditional twist barbed wire, razor type barbed wire

Surface treatment: Electric galvanizing, hot dipped galvanized, PVC sprayed coating and PVC dipped coating

Single Twisted Barbed Wire; Double Twisted Barbed Wire; Traditional Twisted Barbed Wire

Wire diameter for barbed wire: 1.2-3.2mm

Barb distance: 3-6inches

Barbed length: 10mm-65mm

General Use: Barbed wire mainly serves in protecting of grass boundary, railway, highway, etc.

All of the products can be made according to customer's favor

Packed in roll, then put on wooden pallets or according to your requirement

Detailed specification and key data for barbed wire

Wire gauge: BWG 10#-20# 1.4mm-3.0mm

Detailed gauge: BWG 10# x 12#, 12# x 12#, 12# x 14#, 14# x 14#, 14# x16#, 16# x 16#, 16# x 18# or it can be made as your demanding

Finish: Electro galvanized, hot dipped galvanized, PVC coated

Barb distance(distance between one barb and another): 1.5-15cm

Packing: Normally 10-20kg per coil or tap. The weight can be also as the order

Packing details:

1. By bulk

2. Wrapped by hessian or water-proof paper

3. By cardboard then pallets

4. Customer choice

15 years factory and rich experienced sales workers! ! !

Welcome guest from all over the world...

Galvanized Wire | |||||

Kinds | Electro galvanized wire | ||||

Hot galvanized wire | |||||

PVC coated wire | |||||

Material | low carbon steel wire | ||||

Packing | 25-50kg/coil | ||||

Inner plastic and outer hessian cloth | |||||

Gauge | Gauge | SWG mm | BWG mm | In Metric System mm | |

8# | 4.06 | 4.19 | 4.00 | ||

9# | 3.66 | 3.76 | - | ||

10# | 3.25 | 3.4 | 3.50 | ||

11# | 2.95 | 3.05 | 3.00 | ||

12# | 2.64 | 2.77 | 2.80 | ||

13# | 2.34 | 2.41 | 2.50 | ||

14# | 2.03 | 2.11 | - | ||

15# | 1.83 | 1.83 | 1.80 | ||

16# | 1.63 | 1.65 | 1.65 | ||

17# | 1.42 | 1.47 | 1.40 | ||

18# | 1.22 | 1.25 | 1.20 | ||

19# | 1.02 | 1.07 | 1.00 | ||

20# | 0.91 | 0.89 | 0.90 | ||

21# | 0.81 | 0.813 | 0.80 | ||

22# | 0.71 | 0.711 | 0.70 | | |

FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your SA Market Hot Dipped Galvanzied Barbed Wire 10kg per Roll 1kg Per Roll?

One of the most biggest manufacturer & supplier of wires and wire mesh,is a large-scale professional UAE Market Electric Galvanised Wire BWG 20 0.7mm Hot Dipped Galvnised Wire factory in China. Annually more than 10000 tons wires and wire mesh are exported to markets all over the world. Different kinds of wires and mesh are available according to customer’s requirements.

②What is your Technical Information oft SA Market Hot Dipped Galvanzied Barbed Wire 10kg per Roll 1kg Per Roll?

1).Material: super carbon steel

2).Processing by drawing, hot-dip zinc-plating

3).Standard wire gauge from 8# to 24#

4).Thick zinc-coating layer

5).Super in corrosion resistance

6).Firm coating layer

7).Custom size available

10 to 15g Zinc Coating and 35kg Tensile Strength Iron Wire Electro Galvanized Iron Wire

③How long can we receive the product after payment?

In the purchase of Galvanized Iron Wire within three working days, We will arrange the factory delivery as soon as possible. The pacific time of receiving is related to the state and position of customers. Commonly 15 to 20 working days can be served。

SA Market Hot Dipped Galvanzied Barbed Wire 10kg per Roll 1kg Per Roll

- Q: How much wire is required?

- google awg wire table and find the resistivity of nichrome wire it will have wire of different diameters listed. 1/32 is .031 or 31 mils in diameter which closely approximates 20awg wire 20awg nichrome60 wire has 659 ohms per thousand feet An example if it says 10,243 ohms/1000' you will need (2.2/10,243) * 1000 feet of wire for your resistor to Neville:--- The wire doesn't know what system of units you used to calculate the answer. It works fine in English units.

- Q: would the wiring harness on a 1.8 acura integra engine fit a 1.6 honda civic harness?

- Yes.. As long as its an OBD0 to OBD0, OBD1 to OBD1, OBD2 to OBD2 and if it Vtec or non Vtec. If you try to swap an OBD1 to OBD2 don't work, and vise versa, If both are OBD2 and are both Vtec. yea it will work, you'll just have a couple of wire left if you use the harness from a 1.8 Vtec.

- Q: hello,i have lots of 8 gauge wire resting at my closet. And i'm very interested on doing the big 3 upgrade to my 2000 mitsubishi eclipse gt. May i see any improvement with 8 gauge wire?...i know that at least 4 gauge is recommended...but i dont want to spend money.

- Go cheap, get cheap. Improvement, maybe. But heres a secenario: current draw exceeds capacity of 8 gauge wire, insulation melts, positive wire grounds out, lots of smoke, fire.... no wait... FIRE! Oh s**t that's gonna cost me..... (a lot more than 4 gauge wire I'll bet...)

- Q: im throwing in a radio in my 2002 f-150 and i need the color codes for the truck radio wires

- radio wires 2002 150

- Q: Would crepe paper stick on chicken wire?

- Crepe paper needs an adhesive to make it stick to a surface, such as white glue. However, it gets messy once dampened, as the colors may bleed. Instead, I would consider working with paper mache or plaster gauzing strips, which would provide a strong skin over the chicken wire. Both can be primed with gesso then decorated with acrylic paints. If this is a sculptural piece you want to keep, we would also suggest varnishing it for protection.

- Q: I know I am suppose to run the RCA cables and power cables on opposite sides of the car, but which side do I put the speaker wires on, ps I have an amp so I'll be running the wires from my trunk

- in my car i ran the speaker wires on the same side as the RCA's

- Q: where can i buy these type of wires (copper insulated wires)??

- You can buy it at the suggested locations. Insulated wires come in many types for various uses. Be sure the person you buy it from knows the use for which you are buying it. For instance, wire or cable for underground use is far different from house wiring.

- Q: I am replacing a 2 wire circuit for a fan/light combo with a 3 wire fan/light combo switch. I ran a new 12/2 w/grnd to the switch box. I ran a 12/3 w/grnd to the ceiling box for the fan. I have a ceiling fan and light control switch that control light and fan separately. I can't figure out which wires go to what.

- Even though you gave an excellent explanation of the problem it is still too difficult to give you a proper answer without seeing the situation. If you have the money it is best for you to hire a pro. If not, then do you have a friend who knows a lot about wiring. The short you speak of is troubling and could be dangerous. You need to fix the problem soon. So get a pro or a qualified friend.

- Q: okay my apt building was built in 1975 I am changing my light fixture new from home depot and the ground wire, the black and white wire are basic on the new fixture. I am looking in the case box in my ceiling all I see is a black wire attached to red, and a yellow wire attached to a white wire which then attaches to another two white wires (then gos go's up behind the casing) I am not sure which is the ground here. There is a copper looking wire that is thick, thick it just isnt as malleable as the new ground wire that is on my new light fixture. It seems very difficult to maneuver.. Could this be my ground from the ceiling. It was attached to the mount of the old fixture my a screw.

- The wire that was attached to the mount is your ground. (It should be thicker than the one from the fixture. - Use a 'wirenut' to make the connection.) The White wires will be your 'Neutrals'- 'White' from your new fixture. For the 'Black' from the fixture, use the same wire that was connected to the old fixtures 'black'. If you didn't keep track of which is which, then you are now 'in over your head'. Get experienced help before you cause damage or hurt yourself.

- Q: I am building an ice chest boombox and want to wire a toggle (on/off) switch to turn the amp on and off....the amp is wired directly to the battery....my question is that I am using 6 gauge wire....but can't find any female spade connectors that are 6 or even 4 gauge to hook to the terminals on the switch.....what is a simple way to do this....am I going to have to solder the wire straight to the terminals?

- Why not wire the toggle switch into the remote + wire? The one that turns the amp on and off with the head unit. 7/5/2013**** Leave the power supply wire alone. The thick 4 gauge wire that runs from the battery directly to the amp, leave it alone, don't put a toggle switch inline on that wire. Instead there's a wire from your head unit (or ignition) that runs to your amp, it turns on the amp when the head unit turns on or your ignition key is in the on position. It's usually 16 or 14 gauge. That's the wire where the toggle switch belongs. Look at your amp, this wire I am speaking of is probably labeled remote+ or ign or something like that and it's usually located next to your power and ground connections on the amp.

Send your message to us

High Tensile Galvanized PVC Coated Barbed Iron Wire for Security

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches