Injection molding machine LOG-650S8 QS Certification

- Loading Port:

- Ningbo

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 100000 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Condition: | New | Type: | Tube Head Injection | Style: | Horizontal |

| Brand Name: | LOG | Model Number: | LOG 650S8 | Place of Origin: | Zhejiang, China (Mainland) |

| Plastic Type: | Thermoplastic | Automatic: | Yes | Injection Weight: | 2488 |

| Clamping Force: | 6500kn | Opening Stroke: | 920mm | Power(W): | 29+29kw |

| Certification: | CE | After-sales Service Provided: | Engineers available to service machinery overseas |

Packaging & Delivery

| Packaging Details: | 20GP,40GP,40HQ |

| Delivery Detail: | 30 Days |

Product performance and advantages:

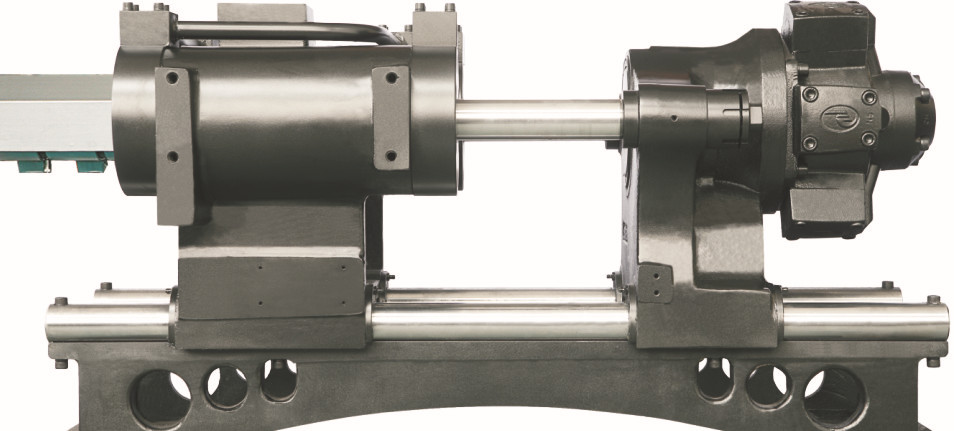

1. Servo energy-saving system

Using the servo motor oil electricity composite structure

2. Servo motor high response feature

It costs only 0.05s for servo energy saving injection molding machines to achieve the maximum output, in comparison with conventional hydraulic injection molding machines. The response speed has been obviously increased, improving the production efficiency.

3. Unique function

Large colored screen with TFT interface

Full automatic close-loop control

Module design of hardware

Auto-tune PID temperature control

Pc interface USB, PIC, and FLASH…

Curve monitoring and analysis function

K-can data transmission (500Kbit/s)

On-line central monitoring function

LOG-650S8 Technical parameters

Description | Unit | LOG-650S8 | ||

international recognized models | 4640/650 | |||

injection | A | B | C | |

Tjeoretical injection volume | cm³ | 2160 | 2734 | 3376 |

Shot volume | g | 1966 | 2488 | 3072 |

Oz | 68.8 | 87.1 | 107.5 | |

Screw diameter | mm | 80 | 90 | 100 |

Injection diameter | mpa | 215 | 170 | 138 |

Screw L:D ratio | 23.6:1 | 21:1 | 19:1 | |

Scerw steoke | mm | 430 | ||

Screw rotate speed | r/min | 0-125 | ||

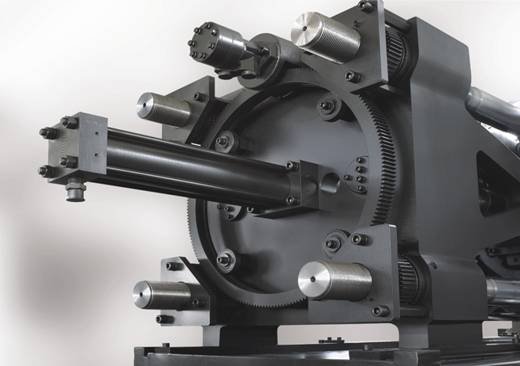

CLAMPING UNIT | ||||

Clamping force | kN | 6500 | ||

Opening stroke | mm | 920 | ||

Platen size | mm*mm | 1320*1290 | ||

Space between tie bars | mm*mm | 930*900 | ||

Maldthickness | mm | 350-910 | ||

Platen Mix stroke | mm | 1830 | ||

Ejection stroke | mm | 265 | ||

Ejcetion force | kN | 182 | ||

Power/Elcetric Heating | ||||

Hydralic system pressure | Mpa | 17.5 | ||

Pump motor | kw | 29+29 | ||

Heating power | kw | 51.6 | ||

Number of temp.conteol | 6+nozzle | |||

Other | ||||

Cycle time | sec | 6.0 | ||

Tank volume | L | 1500 | ||

Machine dimesions | m*m*m | 9.6*1.9*2.3 | ||

Weight of machine | kg | 36000 | ||

The person designing the mold chooses whether the mold uses a cold runner system or a hot runner system to carry the plastic from the injection unit to the cavities. A cold runner is a simple channel carved into the mold. The plastic that fills the cold runner cools as the part cools and is then ejected with the part as a sprue. A hot runner system is more complicated, often using cartridge heaters to keep the plastic in the runners hot as the part cools. After the part is ejected, the plastic remaining in a hot runner is injected into the next part.

- Q: 110 tons injection molding machine injection quantity is how many grams?

- This specific is too clear, you still go to ask the professionals in the field of injection molding machine

- Q: What are the main parts of an injection molding machine?

- (3) hydraulic system hydraulic transmission system is to realize the injection molding machine according to the process of the various actions required to provide power, and meet the injection molding machine parts of the pressure, speed, temperature and so on. It is mainly composed of each kind of hydraulic component and hydraulic auxiliary component, in which the oil pump and the electric motor are the power source of the injection molding machine. Various valves control the oil pressure and flow rate to meet the requirements of the injection molding process. (4) the electrical control system, the electrical control system and the hydraulic system coordinate reasonably, may realize the injection molding machine craft process request (pressure, temperature, speed, time) and each kind of procedure movement. Mainly by electrical appliances, electronic components, instruments, heaters, sensors and other components. Generally there are four kinds of control, manual, semi-automatic, automatic adjustment.

- Q: How many tons is the injection machine of 4 Ann?

- Ann is the name of Hongkong in the last century. Ann means the amount of injection, and tons, that is, clamping force. generally speaking3 Ann -----60T4 Ann -----90T7 Ann -----120T10 Ann -----160T14 Ann -----210T17 Ann -----250T

- Q: Can polyurethane (PU) material be molded by injection molding machine?

- PU according to the hardness can be divided into a variety of, can be injection molding, molding temperature between 170-210. Shoes materials, wheels are used more

- Q: What are the famous brands of injection molding machines?

- There are Chun, Haida, Haitai, Ge, Hai Fei, Bo, YIZUMI, ohplasSouth Korea, LG, Canada, HUSKY, Taiwan

- Q: What products can be produced by injection molding machine?

- we can choose to do energy-saving energy-saving servo servo injection molding machine, has become an industry trend of energy-saving injection molding machine, Levin Bullock company as a professional manufacturer of servo energy-saving injection molding machine, the successful transformation of hundreds of cases, the average energy saving rate is more than 50%, free trial, free to do the program, customer service warranty of two years, to speak with the effect, if you have other questions, you can Baidu A bit of "servo energy efficiency", that has their official website. Can do a detailed understanding.

- Q: Not transformer. It's wires and meters. Because the transformer is public. If 10 kilowatts is not enough. How much is enough?

- You should be talking about the transformer capacity! 10 kilowatts is far from enough. Even if it was barely brought up, it would have a great impact on the life of the equipment.The wire is good. The meter is for the current!

- Q: transparent parts inside the bubble, how to solve this problem, non -, what is the cause?

- First of all, we should first analyze where this gas comes from, and how to prevent and reduce the generation of gas.First, when the particles melt in the screw, it will produce smoke. Second, the mold cavity itself contains air, at the time of injection if the air line out will be wrapped into the material to. Third, the moisture in the material produces water vapor at high temperature. (do not think that the drying temperature and time are enough, it must be dry, and wet weather will not be dried by ordinary dryers)From these three directions to improve, first, reduce the material temperature (reduce the production of smoke). Two, slow down the injection rate (which is good for the exhaust gas). Three increase mold temperature (improve material flow due to lower material speed). Four, fully guarantee the drying of materials (PC and PA66 moisture content must be less than 0.03%). Five, the mold into the glue point to enlarge (conducive to the actual effect of packing). Six, the increase in back pressure (effectively increase the density of the material). Seven, the mold exhaust should be guaranteed.From the above points by item examination and improvement, the problem will certainly be solved.In addition, just look at the picture, playing this bubble, the process must be a problem.

- Q: What is low voltage protection (injection molding machine)?

- Low pressure protection is to prevent the mold cavity foreign body, avoid too much pressure, damage to the moldUsually by the low pressure clamping mode, time, stroke, pressure, three conditions to coordinateFor example, the low pressure lock mode time out, the mold will automatically open and stop alarm, play a role in protecting the mold

Send your message to us

Injection molding machine LOG-650S8 QS Certification

- Loading Port:

- Ningbo

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 100000 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords