2016 High Quality Injection Molding Machine LOG-650A8

- Loading Port:

- Ningbo

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 720 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

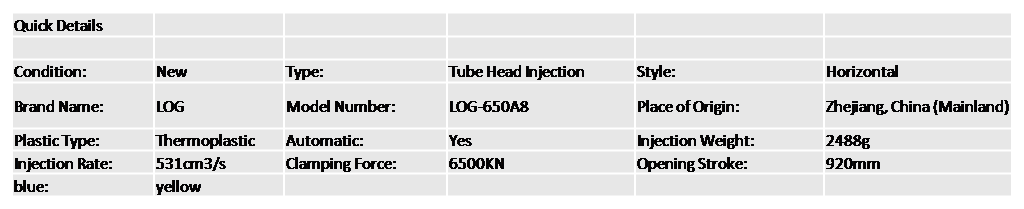

| LOG-650A8 | ||||

| International size rating | 4640/650 | |||

| INJECTION | A | B | C | |

| Shot volume | cm3 | 2160 | 2734 | 3376 |

| Shot weight | G | 1966 | 2488 | 3072 |

| OZ | 68.8 | 87.1 | 107.5 | |

| Screw diameter | mm | 80 | 90 | 100 |

| Injection pressure | mpa | 215 | 170 | 138 |

| Screw L:D ration | 21:01 | 21:01 | 19:01 | |

| Screw stroke | mm | 430 | ||

| Screw speed(stepless) | r/min | 0-125 | ||

| CLAMPING UNIT | ||||

| Clamping force | kn | 6500 | ||

| Opening stroke | mm | 920 | ||

| Platen size | mm×mm | 1320X1290 | ||

| Space between fie bars | mm×mm | 930X900 | ||

| Mold fhickness(Min-Max) | mm | 350-910 | ||

| Max.daylingt | mm | 1830 | ||

| Hydraulic ejection stroke | mm | 265 | ||

| Hydraulic ejection force | kn | 182 | ||

| POWER UNIT | ||||

| Hydraulic system pressure | mpa | 17.5 | ||

| Pump motor | kw | 55 | ||

| Heating capacity | kw | 38.3 | ||

| Number of femp confrol zones | \ | 6+ nozzle | ||

| GENERRL | ||||

| Dry-cycle fime | Sec | 6 | ||

| Oil fank capacify | λ | 1500 | ||

| Machine dimensions | m×m×m | 9.6X1.9X2.3 | ||

| Machine weight | kg | 36000 | ||

Packaging & Delivery

| Packaging Details: | one machine should shipped in a 40GP and a 20 GP containers |

| Delivery Detail: | a week if it's at stock OR a month |

Specifications

1.high response 2. high precise,3oil saving 4. water saving 5 long warking life

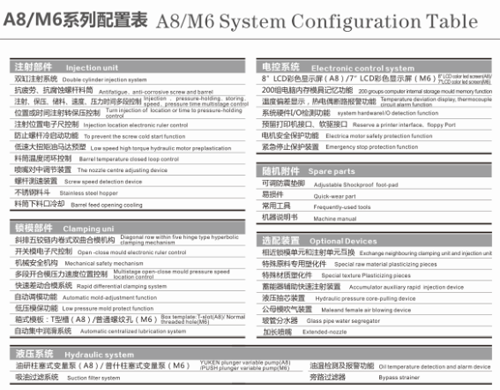

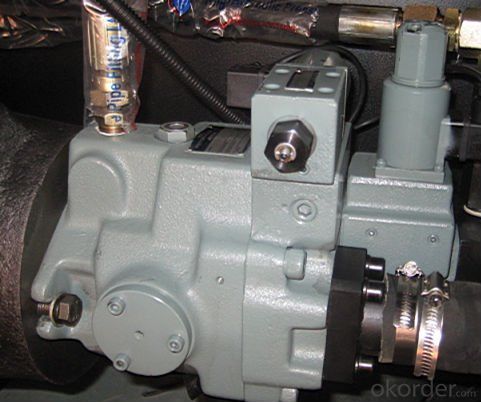

1.template structure of the high-rigidity design,with a bigger clamiping unit. 2. T- slots and conventional screw holes make mold is easy to install. 3 by using our patent bridge structure ,the injection unit will be more stable 4, equipped with imported low-noise and high efficiency variable pump system,saving energy 30% to 60% and and 20 %~40% oil and water 5. high-efficiency filter makes the hydraulic oil clean and a long working life 6. the color screen control system, is conventional to operate it.

- Q: How will the clamping force and injection pressure of injection mould be set?

- According to the product design of the mold to decide, you still find a master, so you can not ask what

- Q: how fast preheating ah, the more detailed the better, do not understand, please do not answer, online, etc.

- Brother, brother, I've just solved the problem. It's too easy... There is a temperature sensing line in the tank. Pull it out. Use a small bottle (put some warm water, not too hot, or higher temperature)... That's it.

- Q: Eternal life injection molding machine screen blue screen what is the reason?

- DKM high speed injection molding machine can be a reboot, complete all reset

- Q: Known diameter and displacement length of screw.

- The injection volume is defined as the maximum volume (L) or maximum weight (g) of the PS injected by the screw at one timeFirst, the volume of wordsV (PS) = (PI /4) * square of screw diameter (DM) * screw injection stroke (DM)

- Q: Adjust the speed of injection molding machine screw speed is what role?

- The rotational speed of the screw can improve the plasticizing degree of the raw material! It has a good effect on uneven coloring of material products! Should not be too fast, too fast will make the production of products decline, surface defects and so on! Usually between 270_350 transfers!Trouble to adopt, thank you!

- Q: Can you tell me if there are 350 grams of three injection molding machines? How much? Thank you

- Well known low-end machines, cheap, should be around 9W.

- Q: The higher the screw speed of the injection molding machine, the higher the oil temperature

- The higher the screw speed of the injection machine, the higher the oil temperature, which is normal, because the screw will rotate continuously and friction of the material, friction will produce heat. We generally cold water machine injection molding machine can be equipped with a mechanical product in Europe, so can increase oil temperature control.

- Q: The first paragraph of the injection molding machine does not rise in temperature. What's the matter?

- Answer: there are several kinds of willing to 1, heating ring bad 2, line short-circuit burned 3, AC contactor damage 4, safety tube burned 5, switch trip 6, temperature line connection error or damage

- Q: How to maintain the injection molding machine?

- The inspection before use is mainly divided into the following steps:1, first of all, check the fuel tank to determine the amount of oil in the standard2. Then check the room heat and oil temperature. The oil should be preheated at room temperature. The room temperature should be treated as heat sink3, and finally check the pressure gauge, whether the swing is serious, can return to zero and mileage statusThe inspection in use is divided into the following steps1. start, overflow valve to minimum pressure2. check and adjust the regulating pressure of overflow valve, whether the continuous rise and fall evenly, all normal, and then transferred to set pressure3. oil pump oil shell electromagnet inspection, the oil temperature 20 degrees -50 degree is normal, the pump shell temperature is 10 degrees higher than the room temperature, -30 degree is normal4. oil leak check5. noise and vibration inspection6. pressure gauge check7. the work of electrical components and the reliability of safety devices are examined8. the fastening nut and screw of each column and cylinder element are looseAfter use, that is, after checking downtime:1. tank oil surface inspection2. check the hydraulic components3., the valve handle position should be restored to the "pressure relief", "stop", "back" position.4. check whether the control switch button and electrical components are loose and sensitive5. machine column and oil bearing movable connection, moving parts filling lubricating oil6. turn off the power and do the work safely

- Q: Injection molding machine first section temperature display 998 what reason?

- If yes, it is a program problemCheck the wrong places, or the small relays or thyristor components on the PLC (or temperature control board)When the power supply system fails, first check whether the AC power supply is connected to the monitor.

Send your message to us

2016 High Quality Injection Molding Machine LOG-650A8

- Loading Port:

- Ningbo

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 720 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords