High Quality Hot Rolled Thick Aluminum Roofing Sheets for Canada

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t

- Supply Capability:

- 10000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of Hot Rolling Thick Aluminum Sheet Description:

Hot Rolling Thick Aluminum Sheets are widely used for building use, decoration use, making cookware, busing making, shipping building, airplane making and so on。Sizes of aluminum sheet for decoration use: Thickness: 0.3mm~300mm Width: Under 2000mm ( Standard: 1000mm, 1219mm, 1500mm, 1540mm) Length: Under 10000mm. Products commonly used in signs, billboards, building exterior decoration, bus body, high factory wall decoration, kitchen sink, lamp, fan, electronic components, chemical apparatus, sheet processing, deep drawing or spinning hollow ware, welding parts, heat exchangers, Bell surface and plate, plates, kitchen utensils, accessories, safety equipment and other.

2.Main Features of Hot Rolling Thick Aluminum Sheet:

Good mechanical properties.

Easy processing, wearability.

Corrosion resistance

Resistance to oxidation.

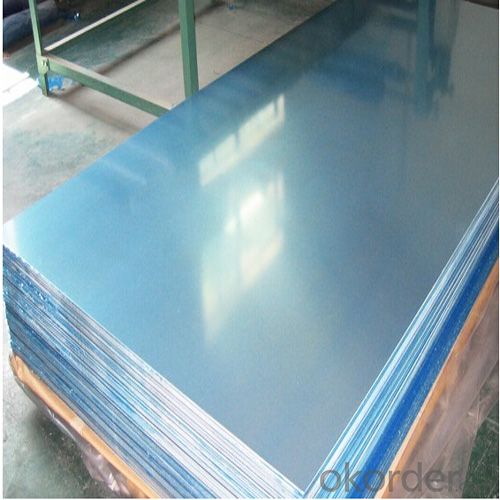

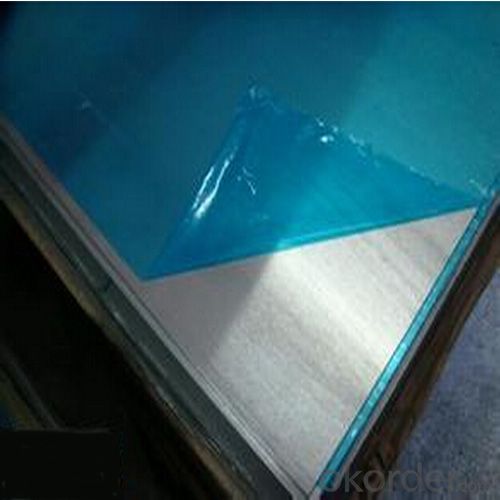

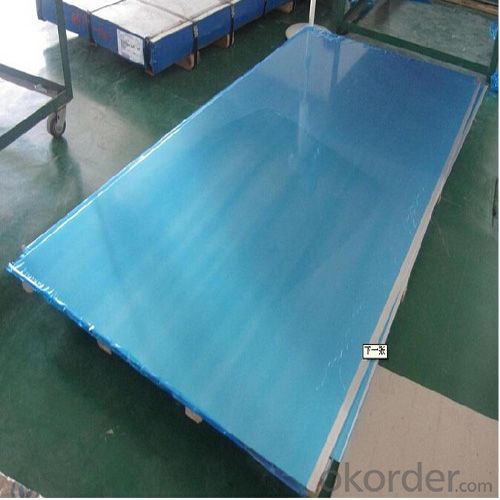

3. Hot Rolling Thick Aluminum Sheet Images:

4. Hot Rolling Thick Aluminum Sheet Specification:

| Aluminium sheet | |||||

| Alloy No. | Thickness (mm) | Width (mm) | Length (mm) | Temper | |

| A1050,A1060, A1070,A1100 | 0.2-100 | 20-2200 | 20-8000 | O,H12,H22,H14,H16,H18, H24,H26,etc | |

| 3A21,A3003,A3105,A3004 | 0.2-100 | 20-2200 | 20-8000 | O,H14,H18,H24,etc | |

| A5052 ,A5005,A5083,A5754 | 0.2-100 | 20-2200 | 20-8000 | O,H18,H24,H32,H34,H111,H112 ,etc | |

| A6061,A6082,A6063 | 0.2-200 | 20-2200 | 20-8000 | T4,T6, T651,etc | |

| A8011 | 0.2-100 | 20-2200 | 20-8000 | O,H12,H22,H14,H16,H18,H24,H26, etc | |

5.FAQ

Q1.How long have you been in this product?

A1:More than 10 years.

Q2. What's the minium quantity(MOQ)?

A2. 5 Metric tons

Q3. How long is shipping time?

A3. 7 (ready-made products)-25 days(OEM)

Q4. How do you guarantee the quality?

A4. 1. Cooperating and Exchaning experience with sevral quoted aluminum companies

2. Japanese and Swiss production line and skilled works (regular training and testing)

3. more than 10 years production experience.

Q5. Do you have after sale service?

A5. Yes. Any quality problem occurs within one year, pls take photoes,we will be responsible.

- Q: Are aluminum sheets available in different colors?

- Aluminum sheets come in various colors, catering to different aesthetic preferences and design needs. These sheets can be coated or painted with a range of shades. The color choices span from classic metallic finishes such as silver and gold to an extensive selection of modern and vibrant colors. This wide availability of colors enables aluminum sheets to be utilized in various applications like architectural cladding, signage, automotive industry, and home décor. Moreover, the color coating or paint on these sheets not only enhances their durability but also offers added protection against corrosion.

- Q: This aluminum is on a mobile home. I trying to repaint it and there is alot of areas were rust has ate the metal away. Especially in the seams. How can I get rid of the rust that already exists and stop it from coming back.

- Uh......... aluminum doesn't rust. Has to be some iron in there somewhere.

- Q: What are the different methods of forming aluminum sheets?

- Aluminum sheets can be formed using various methods, each with its own set of advantages and applications. Below are some examples of these methods: 1. Rolling: The most commonly used method for forming aluminum sheets is rolling. This involves passing a large aluminum ingot through a series of rolling mills, gradually reducing its thickness and increasing its length. The ingot is rolled multiple times until the desired thickness is achieved. Rolling is versatile, as it can produce aluminum sheets of different thicknesses and widths to suit various applications. 2. Extrusion: Another method used for forming aluminum sheets, particularly for complex cross-sectional profiles, is extrusion. In this process, a heated aluminum billet is forced through a shaped die, resulting in a continuous length of aluminum with the desired shape. Extrusion allows for the creation of intricate designs and is commonly employed in the production of structural components and frames. 3. Casting: Casting is a method used to form aluminum sheets with a specific shape or pattern. Molten aluminum is poured into a mold and left to cool and solidify. The mold can be made of different materials, depending on the complexity of the desired shape. Casting is often used for decorative purposes and in the production of architectural panels. 4. Stretch forming: Stretch forming is a specialized method used to form aluminum sheets into curved or contoured shapes. The sheet is clamped at its edges and stretched over a form using hydraulic or mechanical forces. As the sheet is stretched, it takes on the shape of the form, resulting in a curved or contoured sheet. Stretch forming is commonly utilized in the aerospace and automotive industries for components like fuselage sections and car body panels. 5. Pressing: Pressing, also known as stamping or punching, is a method employed to form aluminum sheets into specific shapes or patterns. The sheet is positioned between a die and a punch, and pressure is applied to deform the sheet. The die and punch can have various designs, allowing for the creation of simple cutouts or intricate patterns. Pressing is frequently employed in the manufacturing of automotive parts, appliances, and electronic enclosures. These are just a few examples of the various methods used to form aluminum sheets. Each method offers distinct advantages and is chosen based on the specific requirements of the desired shape, thickness, and application of the aluminum sheet.

- Q: Can aluminum sheets be used for protective enclosures?

- Yes, aluminum sheets can be used for protective enclosures. Aluminum is a lightweight yet durable material that offers excellent protection against various environmental factors such as corrosion, moisture, and UV rays. It is commonly used in industries such as automotive, aerospace, and construction for manufacturing enclosures to shield sensitive components or equipment from potential damage.

- Q: I constructed a small hho generator for experimental purposes. I needed to add a cooling condenser to the unit because of a overheating problem. I was using a old heater core from a vehicle, soldered some joints to make some connections. the solution seemed to have eaten the solder I used, which was normal lead free solder used in water pipes. I was going to invest into a trans cooler core which is made of aluminum, but I need to know if the solution will eat up the aluminum. I also thought about using a condenser core from a broken window a/c, which is made of copper tubing. any advise would be very help full

- Aluminum, yes; copper, no. Aluminum is attacked by both acids and bases (it is what is called amphoteric); copper is attacked by neither -- although nitric acid will attack copper by oxidizing it. Solder joints may be attacked by acid, but may be more or less immune to attack by strong bases, depending on what is in the solder.

- Q: Can aluminum sheet be used for packaging applications?

- Yes, aluminum sheet can definitely be used for packaging applications. Aluminum is widely used in the packaging industry due to its excellent properties. It is lightweight, strong, durable, and malleable, making it ideal for packaging various products. Aluminum sheets can be easily formed into different shapes and sizes, allowing for custom packaging solutions. Additionally, aluminum has excellent barrier properties, providing protection against moisture, gases, and light, which helps to maintain the freshness and quality of the packaged goods. Furthermore, aluminum is non-toxic and can be easily recycled, making it a sustainable choice for packaging applications. Overall, aluminum sheet is a versatile and reliable material for packaging various items, including food, beverages, pharmaceuticals, cosmetics, and many others.

- Q: a 1 kg block of aluminum and a 1 kg block of lead are immersed in water, Both sink, but which experienced the greater buoyant force? Why?

- Buoyant force = weight of water displaced The thing that affects the weight displaced is the volume of the metal blocks. Both Aluminum and Lead have the same mass (1kg) but Lead is more dense than Aluminum (11.34g/cm^3 vs 2.70g/cm^3). As such, the 1kg of Aluminum has a greater volume than Lead and hence experienced the greater buoyant force.

- Q: I want to make a dress from aluminum cans. However, aluminum is very sharp once cut. So, do you thing there is a possible way to make the cut edges less sharp? Would sanding the edges help?

- . The cans will always be sharp. It is possible sand or file aluminum, you will need a brush to clean the sandpaper on file. You could try folding edges to possibly remove some of the some of the sharpness.

- Q: Are aluminum sheets suitable for insulation purposes?

- Indeed, aluminum sheets prove to be well-suited for insulation endeavors. Aluminum, being a notably reflective substance, possesses the ability to effectively impede the transmission of heat, rendering it a superb selection for insulation purposes. With its low emissivity value, aluminum reflects heat radiation rather than absorbing it, thereby aiding in the preservation of a uniform temperature within a given area and diminishing the necessity for heating or cooling. Moreover, aluminum sheets are characterized by their lightweight nature, straightforward installation process, and resistance to moisture, making them an eminently practical choice for insulation in a plethora of applications, including attics, walls, floors, and HVAC systems.

- Q: This question asks about the various types of aluminum foil used specifically for the purpose of food packaging.

- <p>Aluminum foil used for food packaging comes in several types, each with specific applications: 1. Heavy-duty foil: Strong and durable, used for roasting meats and baking. 2. Light-duty foil: Thinner and more flexible, ideal for lining baking sheets and wrapping foods. 3. Reynolds Wrap: A brand known for its non-stick and heavy-duty aluminum foils, suitable for a wide range of cooking and baking needs. 4. Aluminum foil rolls: Available in various widths, used for general food wrapping and sealing. 5. Pre-cut aluminum foil squares: Convenient for individual food portions and small wrapping tasks. Each type offers different levels of heat resistance, malleability, and non-stick properties, catering to diverse food packaging requirements.</p>

Send your message to us

High Quality Hot Rolled Thick Aluminum Roofing Sheets for Canada

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t

- Supply Capability:

- 10000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords