Aluminum Trailer Siding Sheets Canada - Aluminium Cold Rolled Alloy Sheet with Best Price

- Loading Port:

- Shanghai

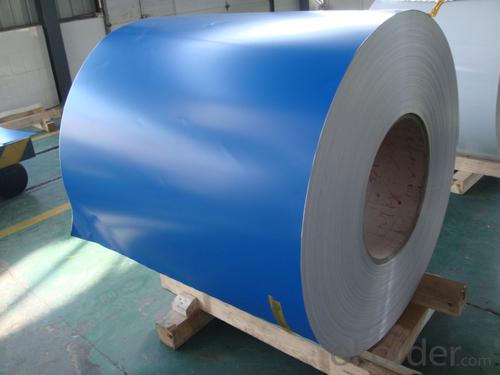

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 4000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Product Description

Cold rolled aluminum sheet and hot rolled aluminium sheet, cold drawn aluminium sheet, and hot drawn aluminium sheet are both widely used in the field of construction field and decoration field, etc. Actually we can provide the above items, besides, the available grade are as follows: 1010, 1050,1060,1100, 2024, 3003, 3005, 3105, 5052,5754,5083,6061,6063,8011, etc.

The temper is include H14, H22, H24, H44,H112,H114,etc.

2. Main features of the product

a. Competitive price

b. Frist-Class Service.

c. Shortest service.

3. Image.

4. Product detailed sizes:

1000mm*2000mm, 1219mm*2438mm,1220mm*2440mm, 1250mm*2500mm,1500mm*3000mm, etc.

5. FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006 or others.

What is the width range?

---It is from 1000mm to 2500mm, etc.

What is the length range:

---It is from 2000mm to 6000mm, etc.

Where is your client from?

---Normally it is from Japan, USA, ENGLISH, SINGAPORE, ETC.

What is your mainly products?

---Normally they are aluminum sheet, checkered sheet,

mirror finish aluminium sheet, aluminum casting coil, etc.

How many tons will be exported in each year ?

----Normally it is around 9000 tons totally.

- Q: Does anyone know how to polish aluminum on a motorcycle that isn't too expensive to do?

- MOTHERS okorder one to do the polishing....then use a fresh one to buff the aluminum. Trust me on this one.....this is the ONLY polish I use on custom bikes.....with this stuff, you can make aluminum look almost like chrome!!!

- Q: Are the aluminum sheets suitable for manufacturing automotive fuel tanks?

- Yes, aluminum sheets are suitable for manufacturing automotive fuel tanks. Aluminum is a lightweight and corrosion-resistant material, making it an ideal choice for fuel tank manufacturing.

- Q: I recently had a new bridge plate and knobs made from aluminum for my guitar. They are bare uncoated aluminum. How would I go about protecting the parts from oxidation and corrosion? I just worry about the bridge plate because of sweat from playing my guitar near the bridge. There are no local places to get the parts chromed or anodized unfortunately.

- Aluminum gets a white coating of aluminum oxide and then does not further react with the air. You can put clear nail polish on the bridge and knobs.

- Q: How do aluminum sheets perform in terms of sound insulation?

- Aluminum sheets do not possess notable sound insulation properties, as they lack significant density and thickness. Instead, they are predominantly utilized in scenarios where their lightweight composition, resistance to corrosion, and thermal conductivity are sought after, rather than for their ability to block sound. For effective sound insulation, alternative materials like rubber, foam, or fiberglass are frequently preferred.

- Q: How do aluminum sheets perform in terms of wear resistance?

- Aluminum sheets have good wear resistance due to their natural ability to form a protective oxide layer on their surface. This oxide layer helps to prevent corrosion and wear, making aluminum sheets suitable for various applications requiring durability and resistance to wear.

- Q: As for cast aluminum sheet or wrought one, which one has faster heat conduction?

- 1,duralumin: it's the alloy of aluminum, copper, magnesium, manganese and other metals. it's suitable for compacting by rolling, and it has a higher strength and hardness than common aluminum products. 2, aluminum: it contains many inpurities, is crisp and easy to be smashed.cast aluminum usually is secondary aluminum, and it is produced by remelting the collected old aluminum pots and spoons.3, wrought aluminum: it contains 98% aluminum and 2% or more inpurities, and is comparatively pure aluminum. its soft priority makes it suitable for being pressed into various shapes, aluminum pots,aluminum lunch box,aluminum sheets,aluminum wires,aluminum pipes are all made by wrought aluminum.you will know their defferences from their definition.

- Q: Explain the distinction between aluminum sheets based on their thickness.

- <p>Aluminum sheets with different thicknesses primarily differ in their strength, weight, and applications. Thicker sheets offer greater strength and rigidity, making them suitable for structural applications or heavy-duty uses. In contrast, thinner sheets are lighter and more flexible, ideal for applications requiring formability or where weight is a concern, such as in the automotive or aerospace industries. The choice of thickness depends on the specific requirements of the project, including load-bearing needs, durability, and aesthetic considerations.</p>

- Q: What are the potential environmental issues that arise from the use of aluminum sheets?

- <p>Yes, there are environmental concerns related to using aluminum sheets. The production process is energy-intensive and contributes to greenhouse gas emissions. Additionally, the mining of bauxite, the primary source of aluminum, can lead to deforestation and habitat destruction. The disposal of aluminum waste can also lead to pollution if not properly managed. However, aluminum is highly recyclable, which can mitigate some of these concerns if recycling practices are adopted widely.</p>

- Q: What's the difference between laser cutting aluminum plate and stainless steel plate?

- The absorptivity of aluminum plate and stainless steel plate to laser is different. The aluminum plate is more reflective and easier to be removed during cutting

- Q: Carbon costs more than aluminum. But there are manufactures who make high quality alloy frames which costs just as much, if not more slightly than mediocre carbon frames.In your opinion, which is better, stiffer, and lighter?If you need examples....umm like Cervelo's S1 or CAAD9 compared to the lower quality carbon frames.

- Personally I would go with the high quality Aluminum because it would be stiffer, but not nesaccarily lighter. A mediocre carbon frame are known to not take stress well and can break more easily than a high quality Aluminum. I would only go with Carbon if it was high quality.

Send your message to us

Aluminum Trailer Siding Sheets Canada - Aluminium Cold Rolled Alloy Sheet with Best Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 4000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords