8mm Thick Aluminum Sheets - Mill Finished Hot Rolled Aluminum Roofing Panels

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of Aluminum Roofing Panels Mill Finished Hot Rollsed

Aluminum Sheets are strengthened and cut from raw materials with different alloys, such as AA5005, AA5052, etc. They are easy for processing in different shapes, good in intensity and can be quickly installed. Aluminium Sheets for Energy Saving Curtain Walls are good in energy saving, weather resistance, fire resistance, easy for maintenance and with many colors.

Aluminium Sheets for Energy Saving Curtain Walls are widely used in construction of metal walls, metal ceilings, car decoration, advertizing panels, etc.

2.Main Features of Aluminum Roofing Panels Mill Finished Hot Rollsed

•High intensity

•Easy to be processed and shaped

•Weather resistance

•Anti-pollution & environment protection

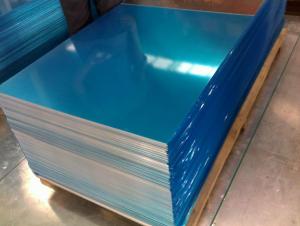

3. Aluminum Roofing Panels Mill Finished Hot Rollsed Images

4.Specification of Aluminum Roofing Panels Mill Finished Hot Rollsed

Alloy Number | AA5XXX |

Temper | H12, H14, H16, H18, H22, H24, H26, H32, HO, F |

Thickness | 0.1mm – 500mm |

Width | 10mm- 2200mm |

Standard | GB/T3880-2006, ASTM, ISO, EU standard |

5.FAQ

A.What about inspections to guarantee quality?

For each order for Aluminum Sheets with Mill Finished Surface AA5XXX, we will arrange strict inspection for raw materials, inspection during production and inspection for finished goods.

With requirement of customers, we also can arrange the third party inspection.

B.What about delivery?

We will put order for Aluminum Sheets with Mill Finished Surface AA5XXX in production schedule after order gets confirmed against copy of TT or L/C. Normally it takes about one month for production. Exact shipment schedule is different based on different sizes and quantity.

C.What is the MOQ?

5 tons for each size.

D. Where have you exported aluminium sheets?

We have exported aluminum sheets to many countries. Main markets include South East Asia, Middle East, North America, South America, etc.

- Q: Are the aluminum sheets suitable for marine vessel construction?

- Yes, aluminum sheets are suitable for marine vessel construction due to their excellent corrosion resistance, high strength-to-weight ratio, and durability in harsh marine environments.

- Q: Can aluminum sheets be used for solar reflectors?

- Yes, aluminum sheets can be used for solar reflectors. Aluminum has a high reflectivity, meaning it can effectively reflect sunlight and reduce heat absorption. This makes it an ideal material for solar reflectors, which redirect and concentrate sunlight onto solar cells or other energy-absorbing devices.

- Q: Is it possible to utilize recycled aluminum scraps as an alternative to purchasing new aluminum sheets for a project?

- <p>Yes, you can use recycled aluminum scraps in your project instead of buying new aluminum sheets. Recycled aluminum is not only environmentally friendly but also cost-effective. It has similar properties to new aluminum, making it suitable for many applications. However, ensure the quality and purity of the recycled aluminum meet your project's requirements. Check for any impurities or inconsistencies that might affect the strength or performance of your final product. If the recycled aluminum is in good condition and appropriate for your needs, it can be a sustainable and economical choice.</p>

- Q: What are the different methods of surface protection for aluminum sheets?

- Aluminum sheets can be protected in various ways to ensure their longevity and functionality. Anodizing is a widely used technique, involving the creation of a protective oxide layer on the aluminum surface. This is achieved by immersing the sheets in an electrolyte solution and passing an electric current through them. The outcome is a resilient and corrosion-resistant layer that can be further enhanced with different dyes and sealants. Another option is powder coating, which entails applying a dry powder onto the aluminum sheets and then curing it with heat. This results in a robust coating that offers excellent defense against scratches, chemicals, and weathering. Powder coating is available in a wide array of colors and finishes, making it a popular choice for decorative purposes. Chemical conversion coating is yet another alternative, involving the treatment of aluminum sheets with a chemical solution to convert the surface into a protective layer. This coating not only improves corrosion resistance but also provides a suitable base for paint or other coatings. Painting is a commonly utilized method for safeguarding aluminum sheets. Different types of paints, such as epoxy, acrylic, and polyurethane-based coatings, can be applied to the surface. These paints not only shield against corrosion and environmental factors but also offer the opportunity for aesthetic customization. Lastly, laminating is a technique where a protective film is applied to the surface of the aluminum sheets. These films can be made from various materials like PVC, polyester, or polyethylene. Laminating adds an extra layer of protection against scratches, abrasion, and UV radiation. Each method of surface protection for aluminum sheets has its own merits and considerations, which depend on the specific requirements of the application. It is crucial to thoroughly assess the desired level of protection, aesthetic preferences, and budget constraints before selecting the most suitable method.

- Q: Are aluminum sheets fire resistant?

- Yes, aluminum sheets are fire resistant.

- Q: How are the aluminum plates cut?

- Cutting machine or plasma cutting machine, laser cutting, or electric saw. Generally thin aluminum (below 0.5mm) can be cut with a blade.

- Q: Are aluminum sheets suitable for use in electrical applications?

- Aluminum sheets are indeed appropriate for utilization in electrical applications. The reason for this appropriateness lies in aluminum's remarkable ability to conduct electricity. Its exceptional conductivity enables the efficient transmission of electrical current. In fact, aluminum sheets are frequently employed in electrical applications including power transmission lines, electrical wiring, and electrical enclosures. Furthermore, aluminum's lightweight nature facilitates easier handling and installation. It also possesses resistance against corrosion, ensuring prolonged durability and reliability within electrical systems. Nevertheless, it is crucial to acknowledge that aluminum exhibits lower conductivity in comparison to copper. Consequently, compensating for this disparity may require the use of larger gauge sizes. In summary, aluminum sheets serve as a feasible and cost-effective choice for a variety of electrical applications.

- Q: Are aluminum sheets resistant to abrasion?

- Indeed, aluminum sheets exhibit a general resistance to abrasion. Renowned for its sturdy nature and robustness, aluminum proves impervious to scratches or harm induced by abrasion. Nevertheless, the degree of resistance may fluctuate contingent upon the particular alloy and thickness of the aluminum sheet. Sheets boasting greater thickness and higher alloy content typically offer superior protection against abrasion. Furthermore, the surface finish of the aluminum sheet can also influence its resistance to abrasion. All things considered, aluminum sheets present a dependable option for enduring abrasion in a myriad of applications.

- Q: What are the different types of alloys used in aluminum sheets?

- There are several types of alloys used in aluminum sheets, including 1100, 3003, 5052, and 6061. These alloys have different properties and are chosen based on the specific application and desired characteristics of the aluminum sheet.

- Q: What unique cleaning techniques should be employed when cleaning aluminum sheets?

- <p>Yes, there are special cleaning methods for aluminum sheets. It's important to use a gentle, non-abrasive cleaner to avoid scratching the surface. Avoid using harsh chemicals or abrasive materials that can damage the aluminum. Instead, use a soft cloth or sponge with a mild detergent solution. Rinse thoroughly with water to remove any cleaning residue, as some detergents can leave a film on the aluminum. Dry the aluminum sheet immediately after rinsing to prevent water spots. Regular cleaning can help maintain the appearance and longevity of aluminum sheets.</p>

Send your message to us

8mm Thick Aluminum Sheets - Mill Finished Hot Rolled Aluminum Roofing Panels

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords