Airplane Aluminum Sheets AA1070 for Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of Aluminum Sheets AA1070 Used for Construction Description

Aluminum Sheets AA1070 is one semi-finished aluminium material.The Aluminum Sheets AA1070 is widly used in building, industry ect. Its weight is much lower than steel. So many customers choosed aluminium material instead of steel.

Aluminum Sheets AA1070 Used for Construction is widely used for electronics, instruments, lighting decoration, packing industry, house decoration, curtain wall, honeycomb-core panel, sandwich panel, aluminum composite panel and aluminum composite pipes.

2.Main Features of Aluminum Sheets AA1070 Used for Construction

a.Competitive price---We have our own mills and can produce mill finished aluminium coils, so we can control the production cost better.

b.Professional after-sale service---We have more than 15 years exportation experience and you need not worry about the exporation problems.

c.Fast delivery time---We can control the delivery time within 35 days.

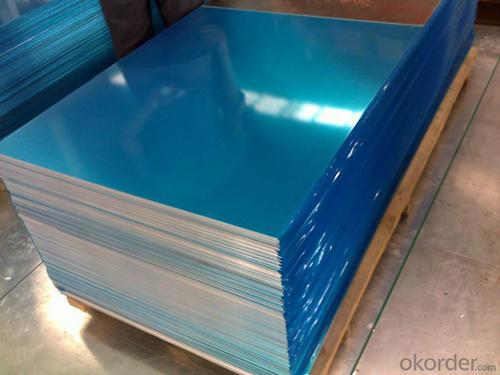

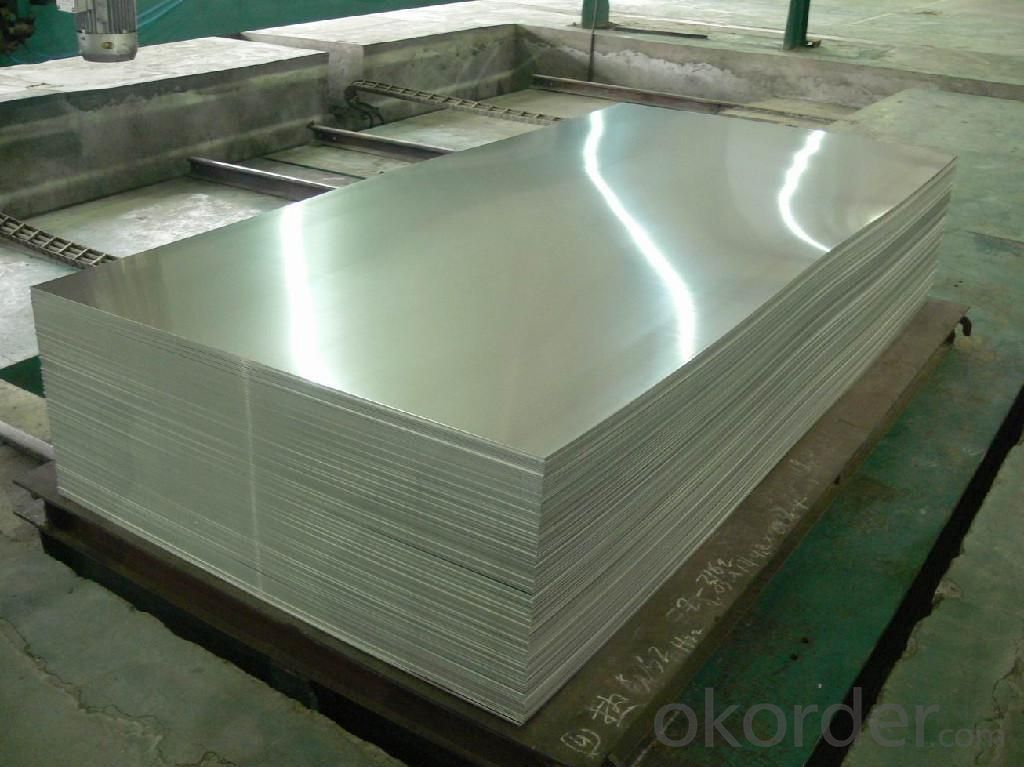

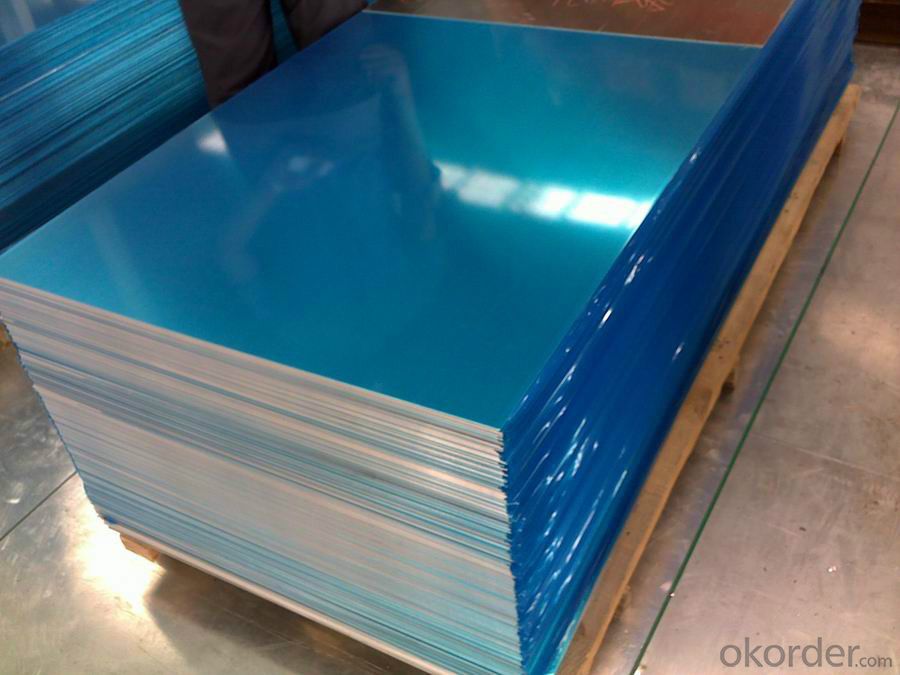

3.Aluminum Sheets AA1070 Used for Construction Images

4.Aluminum Sheets AA1070 Used for Construction Specification

Alloy | AA1070 |

Temper | H14, H16, H18, H22, H24, H26, H32, O/F |

Thickness | 0.2mm -- 100mm |

Width | 30mm -- 1700mm |

Standard | GB/T 3880-2006,EN,ASTM,JIS |

5. FAQ of Aluminum Sheets AA1070 Used for Construction

A.How to guarantee the quality?

Customers are welcome to our mill to visit and check the products. Besides, we can arrange a third party to test Aluminum Sheets AA1070 Used for Construction.

B.When will you deliver the products?

Aluminum Sheets AA1070 Used for Construction will be delivered within 35 days after receiving advanced payment or original L/C.

- Q: For a high school Chemistry course I made soap for a project. Before doing this, thank god, i learned that one should never use an aluminum container to mix the lye (NaOH) and water. Now, I need to know why. I know it eats away at the container but i can't figure out why. It goes against everything I've learned so far. At first i thought it was because Aluminum was, for some strange reason :o, more reactive than Sodium therefore replacing it in the reaction but that turned out not to be true. Does anyone have an idea of why? Thanks

- This exact question, word for word, was asked and answered 7 months ago. See my source for the answer. And find something better to do than reposting old questions.

- Q: What are the different surface finishes available for aluminum sheets?

- Some of the different surface finishes available for aluminum sheets are mill finish, brushed finish, anodized finish, and embossed finish. Mill finish is the natural appearance of the aluminum without any additional treatment. Brushed finish involves brushing the surface to create a textured appearance. Anodized finish involves an electrolytic process that forms a protective layer on the surface and can be colored. Embossed finish involves creating patterns or designs on the surface using pressure or heat.

- Q: Does aluminum foil keep food warm or cool, or is it just a convenient material to cover food with?

- all i know is that it keeps food hot.

- Q: Can aluminum sheets be coated with other materials?

- Yes, aluminum sheets can be coated with other materials. This process is known as aluminum sheet coating or aluminum sheet finishing. Coating aluminum sheets with other materials serves multiple purposes, such as enhancing their appearance, protecting against corrosion, improving durability, and providing insulation. There are various methods to coat aluminum sheets, including painting, anodizing, laminating, and powder coating. Each method offers different benefits and is chosen based on the desired outcome and intended use of the coated aluminum sheet. Coating aluminum sheets with other materials allows for customization, versatility, and increased functionality in a wide range of applications, including construction, automotive, aerospace, and consumer goods industries.

- Q: Nissan A1100P aluminum plate is equivalent to what brand of domestic, where there are relevant information and instructions, mechanical design manuals or other materials manuals? Thank you.

- 1, aluminum plate A1100P equivalent to national standard AL1100 aluminum plate.2 and 1100 are pure aluminium, the content of aluminium is 99%, which can not be improved by heat treatment. With high corrosion resistance, electrical conductivity and thermal conductivity, and its small density, good plasticity, through pressure processing can produce all kinds of aluminum, but the strength is low.

- Q: Aluminum plate thickness 3 mm, what is the allowable error in the national standard thickness?

- The allowable deviation of plate thickness in GB/T3880.3-2006 "general industrial aluminum plate, strip and Aluminum Alloy third part:" size deviation provisions, I have the standard download URL sent to you a message, please check.The deviation is divided into ordinary and high level, +0.10, -0.12

- Q: How do you prevent oxidation of aluminum sheets?

- To avoid oxidation of aluminum sheets, several techniques can be utilized. One commonly used method is to apply a protective coating or finish on the surface of the aluminum sheets. This coating acts as a barrier between the aluminum and the external environment, preventing the metal from reacting with oxygen and forming an oxide layer. There are various types of coatings available for this purpose, such as anodizing, painting, and powder coating. Anodizing involves creating a controlled oxide layer on the aluminum surface through electrolysis. This oxide layer is highly resistant to corrosion and provides excellent protection against oxidation. Painting and powder coating, on the other hand, involve applying a layer of paint or powdered polymer to the aluminum surface. These coatings create a physical barrier that shields the metal from oxygen and moisture. Another effective approach to prevent oxidation is by using aluminum alloys that have enhanced corrosion resistance. These alloys are specifically designed to have a higher resistance to oxidation and can withstand exposure to harsh environments without forming a significant oxide layer. In addition to coatings and alloy selection, proper storage and handling practices play a crucial role in preventing oxidation. It is important to store aluminum sheets in a clean, dry, and well-ventilated area to minimize exposure to moisture and corrosive elements. Contact with acidic or alkaline substances should be avoided, as they can accelerate the oxidation process. Regular cleaning and maintenance of aluminum sheets also help prevent oxidation by removing any contaminants that could promote corrosion. In summary, preventing oxidation of aluminum sheets involves a combination of protective coatings, appropriate alloy selection, and proper storage and handling practices. By implementing these measures, the lifespan and durability of aluminum sheets can be significantly improved.

- Q: I heard somewhere that when aluminum is heated, it releases something that is a known cause of Alzheimers. Is this true? I have a homemade cooker made of aluminum and I don't want Alzheimers.

- Aluminium and aluminium compounds are ubiquitous and we consume up to 50mg a day. The fact that aluminium is present isn't necessarily an indication that it is the cause of Alzheimers, and the consensus is that there are a combination of factors at play including genetic factors. However, there has been research which reveals amyloid plaques, which are protein compounds and aluminium and tangled synapses, which are part of the neuronal network. This is leading researchers to suspect that there is a causal link.

- Q: What's the difference between laser cutting aluminum plate and stainless steel plate?

- The absorptivity of aluminum plate and stainless steel plate to laser is different. The aluminum plate is more reflective and easier to be removed during cutting

- Q: What are some common applications of aluminum sheets?

- Aluminum sheets have a wide range of applications due to their unique properties. Some common applications of aluminum sheets include: 1. Construction: Aluminum sheets are commonly used in the construction industry for roofing, siding, and window frames. Their lightweight nature and durability make them an ideal choice for these applications. 2. Automotive industry: Aluminum sheets are extensively used in the automotive industry to manufacture car bodies, panels, and components. The lightweight nature of aluminum helps reduce the overall weight of vehicles, leading to improved fuel efficiency. 3. Packaging: Aluminum sheets are commonly used for packaging purposes, especially in the food and beverage industry. They are used to make cans, foils, and lids, thanks to their ability to preserve the freshness and quality of the packaged products. 4. Aerospace industry: Aluminum sheets play a vital role in the aerospace industry. They are used to manufacture aircraft bodies, wings, and structural components due to their high strength-to-weight ratio, corrosion resistance, and ability to withstand extreme temperatures. 5. Electrical industry: Aluminum sheets are used in the electrical industry for various applications, including manufacturing electrical enclosures, transformers, and bus bars. Aluminum's excellent conductivity and lightweight nature make it a preferred choice for these applications. 6. Marine industry: Aluminum sheets are widely used in the marine industry for building boats, ship hulls, and other marine structures. Aluminum's resistance to corrosion and its ability to withstand harsh marine environments make it a suitable material for these applications. 7. Decorative purposes: Aluminum sheets are frequently used for decorative purposes in architecture and interior design. They can be shaped, engraved, or coated with different finishes to create aesthetically pleasing surfaces for walls, ceilings, furniture, and signage. These are just a few examples of the common applications of aluminum sheets. The versatility, durability, and lightweight nature of aluminum make it a highly sought-after material in various industries.

Send your message to us

Airplane Aluminum Sheets AA1070 for Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords