Very Thin Aluminum Sheets - Hot Rolled Aluminium Sheet with Best Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 4 m.t

- Supply Capability:

- 200 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of Product Description

Our aluminum sheet/plate/slab is widely used in the field of construction field and decoration field, etc.

There are many different grades, such as: 5000 series, 6000series, etc. The detailed grade are as follows: 1010, 1060,5052,5083,6061,7075, 8011, etc.

The temper is include H14,H24, H44,H112,O, H112, etc.

2. Main features of the product

a.Competitive price

b.Frist-Class Service.

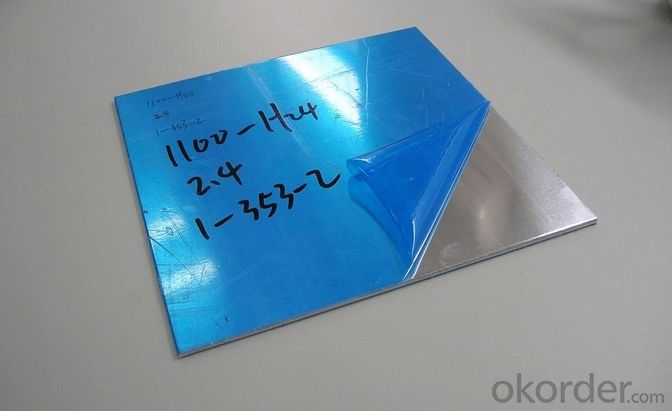

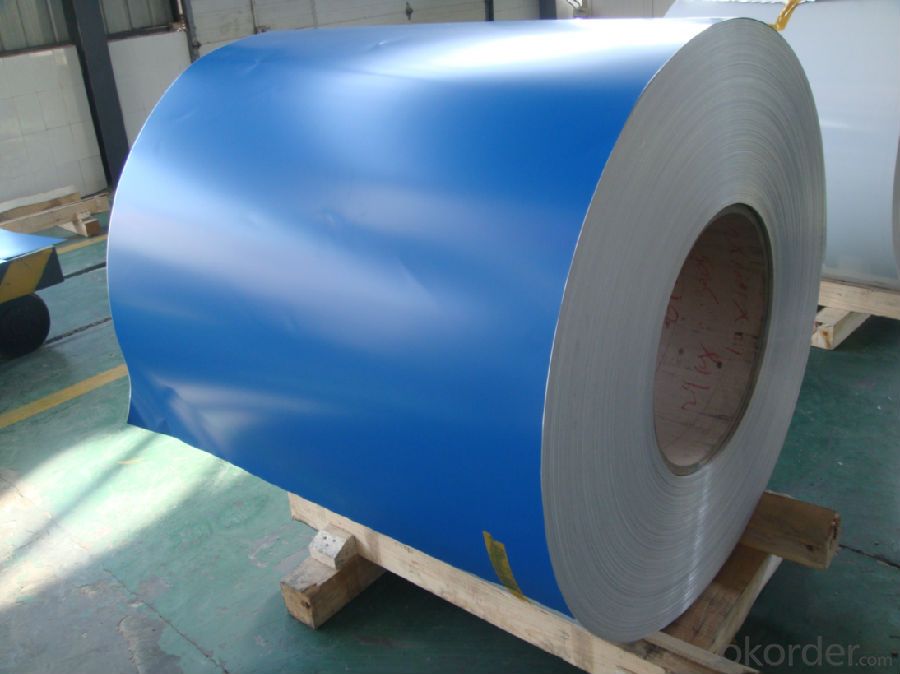

3. Image.

4. Product detailed sizes:

1000mm*2000mm, 1219mm*2438mm, 1220mm*2440mm,etc.

5. FAQ:

---Usually our standard is GB3880-2006 or others.

What is the width range?

---It is from 1000mm to 2500mm, etc.

What is the length range:

---It is from 2000mm to 6000mm, etc.

---Normally it is around 5 tons/each size.

How many tons did you export in one year?

---UAE, USA, Canada, Fiji, Turkey, South Africa, etc.

what is your mainly products?

---Normally they are aluminum sheet,checkered sheet, checkered plate, checkered slab,

mirror finish aluminium sheet, aluminum casting coil, etc.

- Q: I have no idea, and I can't figure this out, and neither can my aunt and she's super smart. It's this project that's due on Monday, and if I can't get it turned in, then I get detention and a failing lab grade. The only information I have is it's $2.96 for a roll of aluminum, it contains 2.96 square meters, and it weighs .995 grams...

- This can be done, as crazy as it sounds. Aluminum has a molar mass of 26.98g and the stated sample (the roll) is $2.96 for 0.995g You would divide 0.955 by 26.98. This gives you 0.0369, which is the amount of moles of aluminum in the roll. Then you need to use Avogadro's number. This is 6.02*10^23, and is the amount of particles in a mole. Avogadro's number multiplied by 0.0369 gives you 2.22138*10^22. This is the amount of aluminum atoms in the roll. Now, you divide the price ($2.96) by the amount of aluminum atoms (2.22138*10^22) to get the price per atom. Price per atom of aluminum in the stated sample: $1.332505*10^-22 (This is equivalent to .$0.0000000000000000000001332505) I hope this helps.

- Q: Are aluminum sheets suitable for cryogenic applications?

- Yes, aluminum sheets are suitable for cryogenic applications. Aluminum has excellent thermal conductivity and low thermal expansion, which allows it to withstand extreme cold temperatures and maintain its structural integrity. Additionally, aluminum has a low density and is lightweight, making it a practical choice for cryogenic applications where weight reduction is important. Aluminum also has good corrosion resistance, further enhancing its suitability for cryogenic environments. Overall, aluminum sheets are a reliable and cost-effective option for various cryogenic applications, such as in aerospace, cryogenic storage tanks, and cryogenic research facilities.

- Q: Can aluminum sheets be used for architectural applications?

- Architectural applications can definitely make use of aluminum sheets. Aluminum, being a lightweight and versatile material, offers numerous advantages for architectural projects. It possesses durability, resistance to corrosion, and the ability to withstand extreme weather conditions, making it an ideal choice for different architectural applications like roofing, cladding, facades, windows, doors, and decorative elements. The availability of aluminum sheets in various thicknesses, finishes, and colors allows architects and designers to achieve their desired aesthetic while maintaining structural integrity. With the material's flexibility in being easily shaped, bent, and formed into complex designs, architects are provided with creative freedom and flexibility. Aside from its aesthetic appeal, aluminum is also an environmentally sustainable choice for architectural applications. It is highly recyclable, contributing to a high recycling rate and promoting eco-friendly options. The use of aluminum sheets in architectural projects helps in reducing the carbon footprint and promoting sustainable design practices. Moreover, aluminum sheets offer excellent thermal and acoustic properties that contribute to energy efficiency and sound insulation in buildings. The material aids in reducing energy consumption and enhancing occupant comfort, making it an attractive option for architects and building owners. In conclusion, the versatility, durability, sustainability, and aesthetic appeal of aluminum sheets make them a popular choice for architectural applications. They provide numerous benefits and can be utilized in various ways to create stunning architectural designs while ensuring long-lasting performance.

- Q: my grandpa gave me a family harloom, a 1971 Honda Trail 90, after it sat in a shed for a good 30 years. i have got most everything in tip top shape except for the polished aluminum has become lightly tarnished. and because i am a perfectionist

- I helped a friend restore an old Honda 160. We did a combination of the things mentioned. We painted the engine cases with a high temp aluminum paint. We did the side covers by wet sanding with 400-800-1000 and then finishing with Semichrome. Other misc bits we went with flat black (makes the polished aluminum pop). It wasn't exactly stock, but it looked great. It would take an expert to know the difference.

- Q: In which autocomponents usage of aluminium is better or otherwise?

- Aluminium is lighter as well as stronger than CI. Thats the reason most of the Automobile manufacturers use Aluminium for car bodies while they use cast iron for the underframes and internal chassis....NMN

- Q: Can aluminum sheets be used in construction?

- Construction can indeed utilize aluminum sheets. Aluminum, a versatile and lightweight material, possesses numerous advantageous properties for construction purposes. Its corrosion resistance allows for both indoor and outdoor applications. Moreover, aluminum sheets exhibit a high strength-to-weight ratio, granting them durability and strength while remaining relatively lightweight. This characteristic proves advantageous in construction projects where weight is a consideration. Furthermore, aluminum is non-toxic and highly recyclable, making it an environmentally conscious option. When combined with its aesthetic appeal and ease of fabrication, aluminum sheets become a favored choice for a variety of construction applications such as roofing, cladding, wall panels, window frames, and more.

- Q: What are the electrical conductivity properties of aluminum sheets?

- Aluminum sheets are equipped with exceptional electrical conductivity characteristics. With its low electrical resistance, aluminum finds extensive usage in diverse electrical applications. It boasts a high conductivity rating, marginally lower than that of copper, rendering it an effective electricity conductor. This attribute enables aluminum sheets to efficiently transmit electrical current with minimal energy wastage. Consequently, aluminum is extensively employed in power transmission lines, electrical wiring, and electrical connectors. Moreover, aluminum's conductivity renders it suitable for applications requiring heat dissipation, such as heat sinks in electronic devices. In general, aluminum sheets are renowned for their favorable electrical conductivity, making them a preferred choice in numerous electrical and electronic applications.

- Q: I want to make a dress from aluminum cans. However, aluminum is very sharp once cut. So, do you thing there is a possible way to make the cut edges less sharp? Would sanding the edges help?

- . The cans will always be sharp. It is possible sand or file aluminum, you will need a brush to clean the sandpaper on file. You could try folding edges to possibly remove some of the some of the sharpness.

- Q: How do aluminum sheets compare to copper sheets in terms of conductivity?

- When it comes to conductivity, aluminum sheets and copper sheets have their differences. Copper is known for its exceptional ability to conduct electricity and is considered one of the most conductive metals available. Its high electrical conductivity allows electricity to flow through it with minimal resistance. On the other hand, aluminum, while still a good conductor of electricity, is not as conductive as copper. In fact, aluminum has about 61% of the conductivity that copper possesses. As a result, if high conductivity is a top priority, copper sheets would be the preferred option. However, if cost-effectiveness and lightweight properties are more important, aluminum sheets can still offer adequate conductivity for many applications. Ultimately, the decision between aluminum and copper sheets relies on the specific project requirements and the balance between conductivity, cost, and other factors.

- Q: What are the mechanical properties of aluminum sheets?

- Aluminum sheets possess several mechanical properties, including high strength-to-weight ratio, excellent corrosion resistance, good formability, and high thermal and electrical conductivity. They are also non-magnetic and non-toxic, making them suitable for various applications in industries such as aerospace, automotive, construction, and packaging.

Send your message to us

Very Thin Aluminum Sheets - Hot Rolled Aluminium Sheet with Best Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 4 m.t

- Supply Capability:

- 200 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords