High Quality Aluminum Wall Sheets for Electric Shells

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description

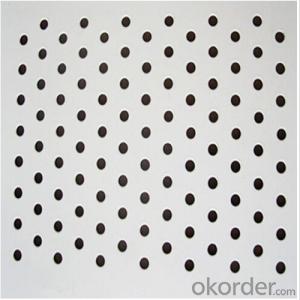

Aluminum sheet checkered /Aluminum sheet embossing sheet

| Material | 1000 series: 1050. 1070. 1100 2025. 2117. 2218. 2618. 6000 series: 6005. 6011. 6053. 6351. 6061. 6101. 6151. 6201. 6261. 6262. 6063. 6463. 6066.6070 7000series: 7001. 7005. 7072. 7075. 7076. 7175. 7178. 7079 8000 series:8011,8021,8079 etc |

| Standard | GB/T17748-2008 |

| Certification | ISO9001,ISO14001, ISO9001:2000 |

| Temper | T4,T5,T6,H111,H112 |

| Surface treatment | Polished,Mill Finished,anodized or power sprayed |

| Features | High weather resistance anti scratch anticorrosion and good weather resistance subtle edges and elegant appearance and easy processing and installation high brightness and hardness |

| Resolution | 2%-98% |

| Advantages | 1)Excellent machining properties 2)Suited to marine and low temp applications |

| Note | If you have any other questin,welcome for your consultation |

1)Chemical compositions&mechanical property&Size

Alloy | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Al |

5005 | 0.30 | 0.70 | 0.20 | 0.20 | 0.50-1.10 | 0.10 | 0.25 | - | spare |

5052 | 0.25 | 0.40 | 0.10 | 0.10 | 2.2-2.8 | 0.15-0.35 | 0.10 | spare | |

5083 | 0.40 | 0.40 | 0.10 | 0.40-1.0 | 4.0-4.9 | 0.05-0.25 | 0.25 | 0.15 | spare |

6060 | 0.30 -0.6 | 0.10 -0.30 | ≤0.10 | ≤0.10 | 0.35~0.6 | ≤0.05 | ≤0.15 | ≤0.10 | spare |

Packaging & Shipping

Package: Standard seaworthy packing or as per request

Transports:Containler sizes:

20ft GP:5898mm(Length)x2352mm(Width)x2393mm(High)

40ft GP:12032mm(Length)x2352mm(Width)x2393mm(High)

Our Services

1 Customer and reputation first

2 Timely feedback

3 Low MOQ

4Timely delivery

5 Competitive price

6Different size can be supplyed as your request

7 Professional service of technical and shipping support

8More than 30 years experience in the cold and hot rolled sheet/coil/stri experience

Photos

- Q: How to distinguish aluminum sheet from magnesium sheet?

- seperately put aluminum sheet and magnesium sheet into NaOH solution, the one generating bubble is aluminum sheet, because aluminum sheet will react with strong base , generating hydrogen.

- Q: Can aluminum sheets be used for cookware?

- Yes, aluminum sheets can be used for cookware. Aluminum is a popular choice for cookware due to its excellent heat conductivity and lightweight nature. However, it is often used as a core material with other coatings or layers added to enhance its durability and prevent chemical reactions with acidic foods.

- Q: Hi everyone, I have this problem that I'm somewhat confused about. The problem is:An alloy of aluminum and magensium was treated with sodium hydroxide solution, in which only aluminum reacts to give hydrogen gas:2Al + 2NaOH + 6H20 --gt; 2NaAl(OH)4 + 3H2If a sample of alloy weighing 1.118 g gave 0.1068 g of hydrogen, what is the percentage aluminum in the alloy?How do I account for the magnesium and what stoichiometric relationships would I need to set-up? This is very confusing, but I appreciate the slightest of help on this!Thank you.

- You don't need to worry about the magnesium at all, because it doesn't enter into the reaction. You have a balanced equation for aluminium and hydrogen, and the data given are sufficient: From the equation, you know that 2 moles of aluminium produce 3 moles of H2. 0.1068 g of H2 were produced, so divide this by molecular mass of H2 (2.016) to determine the moles of H2 produced. You know that 3 moles of H2 would have been produced from 2 moles of Al. Therefore, multiply the moles of H2 by 2/3, to determine the moles of Al that were present. Now multiply this number by the atomic mass of Al, to determine the grams of Al. Now divide this number if grams by 1.118 and multiply by 100 to determine % Al present in the alloy.

- Q: How is aluminum sheet made?

- Aluminum sheet undergoes a rolling process to be manufactured, known as rolling. This process entails passing a preheated aluminum ingot through a succession of rolling mills. The initial step involves heating the ingot to a specific temperature to enhance its malleability. Once heated, the ingot is then fed through a sequence of rolling mills, wherein it is continuously pressed and stretched to reduce its thickness and increase its length. The rolling mills consist of a pair of rotating cylinders with grooves on their surfaces. As the ingot passes through these cylinders, it undergoes compression and elongation, resulting in a thinner and longer sheet. This process is repeated multiple times, with each pass further reducing the sheet's thickness. To maintain the desired thickness and dimensions, the sheet is periodically subjected to annealing. This process involves heating the sheet to a specific temperature and gradually cooling it. Annealing helps alleviate internal stresses and ensures the sheet retains its desired properties. Once the desired thickness is achieved, the aluminum sheet is cooled, trimmed, and either cut into specific lengths or rolled into coils for further processing or distribution. The final product is a flat, thin, and versatile sheet of aluminum that finds applications in various industries, including construction, automotive, packaging, and electrical appliances.

- Q: This question asks about the various types of paint that can be used specifically for aluminum sheets, indicating an interest in paint compatibility and options for this particular material.

- <p>There are several types of paints suitable for aluminum sheets, each offering unique properties. These include: 1. Acrylic Paints - Water-based, easy to apply, and offer good adhesion. 2. Epoxy Paints - Known for their durability and chemical resistance, they provide a strong bond to the metal. 3. Enamel Paints - Provide a hard, glossy finish and are resistant to chipping and scratching. 4. Polyester Paints - Offer excellent durability and UV resistance, making them suitable for exterior applications. 5. Powder Coatings - Applied electrostatically, they provide a tough, scratch-resistant finish. 6. Specialty Paints - Such as heat-resistant or anti-corrosive paints, designed for specific industrial applications. The choice of paint depends on the application, desired finish, and environmental conditions.</p>

- Q: What are the different methods of surface embossing aluminum sheets?

- Aluminum sheets can be embossed using various techniques, each with its own distinct process and result. Some commonly employed methods are: 1. Mechanical Embossing: To create patterns or designs on the aluminum sheet, mechanical tools like rollers or presses are utilized. The sheet is either passed through the rollers or pressed against a surface with a pattern, which impresses the design onto the metal. Mechanical embossing is ideal for repetitive patterns like diamond or checkerplate designs. 2. Chemical Embossing: This technique involves etching or engraving the aluminum sheet using chemical solutions. The solution is selectively applied to the metal's surface, eating away the desired areas to leave an embossed pattern. Chemical embossing enables the creation of intricate and detailed designs on the aluminum sheet. 3. Heat Embossing: By applying heat, embossed designs are formed on the aluminum sheet. A heated die or stamp is pressed onto the metal's surface, causing it to deform and create the desired pattern. Heat embossing is commonly used for raised logos or text on aluminum sheets. 4. Laser Embossing: Laser technology is employed to achieve embossed designs on aluminum sheets. A laser beam is directed onto the metal's surface, vaporizing or melting the desired areas to form the embossed pattern. Laser embossing offers high precision and allows for intricate and complex designs. 5. Roll Embossing: In this method, the aluminum sheet is passed through a series of engraved rolls, which imprint the desired pattern onto the metal. Each roll has a distinct design, providing a range of embossed finishes. Roll embossing is often used for textured or decorative finishes on aluminum sheets. In conclusion, the various techniques for surface embossing aluminum sheets offer multiple options for creating visually appealing and unique designs. The choice of method depends on the desired outcome, complexity of the design, and specific project requirements.

- Q: Can the aluminum sheets be used for manufacturing heat exchanger fins?

- Indeed, the utilization of aluminum sheets is possible in the production of heat exchanger fins. Owing to its remarkable thermal conductivity and resistance to corrosion, aluminum stands as a frequently employed substance in heat exchangers. The lightweight and easily malleable attributes of aluminum sheets render them exceptionally suitable for the creation of fins that possess an extensive surface area, thereby augmenting heat transfer. Furthermore, aluminum is readily accessible and cost-efficient, solidifying its status as a favored selection within the realm of heat exchanger manufacturing.

- Q: What are the properties of anodized aluminum sheets?

- Anodized aluminum sheets have a protective oxide layer that provides increased corrosion resistance, durability, and a decorative finish. They are lightweight, non-toxic, and offer excellent heat and electrical conductivity. Additionally, anodized aluminum sheets are easy to clean, resistant to fading and scratching, and can be dyed in various colors for aesthetic purposes.

- Q: Can aluminum sheets be anodized without affecting their dimensions?

- Aluminum sheets can undergo anodization without significantly impacting their dimensions. Anodization is an electrochemical procedure that produces a protective oxide layer on the aluminum's surface, enhancing its resistance to corrosion and durability. To perform anodization, the aluminum sheet is immersed in an acidic solution while an electric current is passed through it. This causes the aluminum to oxidize, resulting in the formation of an aluminum oxide layer on the surface. Throughout the anodization process, the aluminum oxide layer grows both inward into the metal and on the surface. The growth of the oxide layer can be precisely controlled by adjusting the duration of the anodization process to achieve the desired thickness. Consequently, the dimensional changes induced by anodization are minimal and can be easily accommodated during the design phase. Nevertheless, it is worth noting that anodization can lead to a slight increase in the thickness of the aluminum sheet. This is due to the growth of the oxide layer on the surface. Typically, the increase in thickness is approximately 50% of the overall thickness of the oxide layer. For instance, if the desired oxide layer thickness is 10 micrometers, the resulting increase in sheet thickness would be approximately 5 micrometers. In conclusion, anodizing aluminum sheets can result in a slight increase in thickness, but the dimensional changes are negligible and can be accurately predicted and taken into account during the design phase. Anodization is a widely used and effective method for enhancing the properties of aluminum sheets without significantly altering their dimensions.

- Q: How to solve the loose bonding of aluminum sheet and silica gel?

- Bonding silicone rubber needs surface treatment, after using silicone rubber surface treating agent of Kuer , you can bond them with 4211 adhesive.

Send your message to us

High Quality Aluminum Wall Sheets for Electric Shells

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords