Aluminum Corrugated Metal Roofing Sheets Toronto - Best Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t

- Supply Capability:

- 10000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

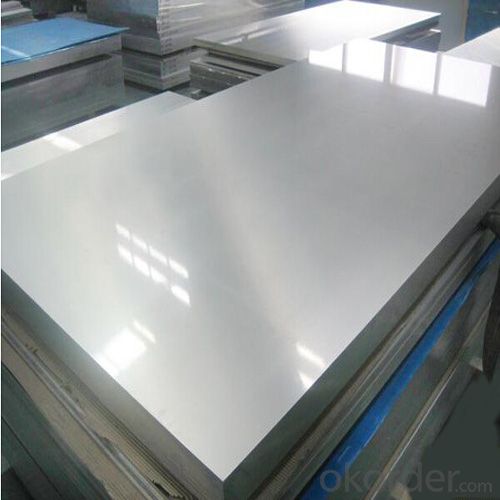

1.Structure of Aluminum Corrugated Metal Roofing Sheet Description:

Aluminum Corrugated Metal Roofing Sheet are widely used for building use, decoration use, making cookware, busing making, shipping building, airplane making and so on。Sizes of aluminum sheet for decoration use: Thickness: 0.3mm~300mm Width: Under 2000mm ( Standard: 1000mm, 1219mm, 1500mm, 1540mm) Length: Under 10000mm. Products commonly used in signs, billboards, building exterior decoration, bus body, high factory wall decoration, kitchen sink, lamp, fan, electronic components, chemical apparatus, sheet processing, deep drawing or spinning hollow ware, welding parts, heat exchangers, Bell surface and plate, plates, kitchen utensils, accessories, safety equipment and other.

2.Main Features of Aluminum Corrugated Metal Roofing Sheet:

Good mechanical properties.

Easy processing, wearability.

Corrosion resistance

Resistance to oxidation.

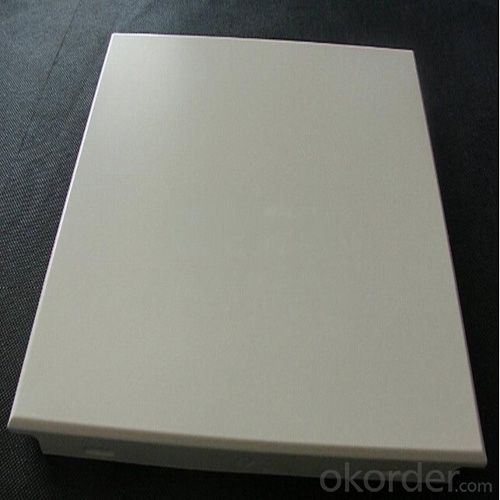

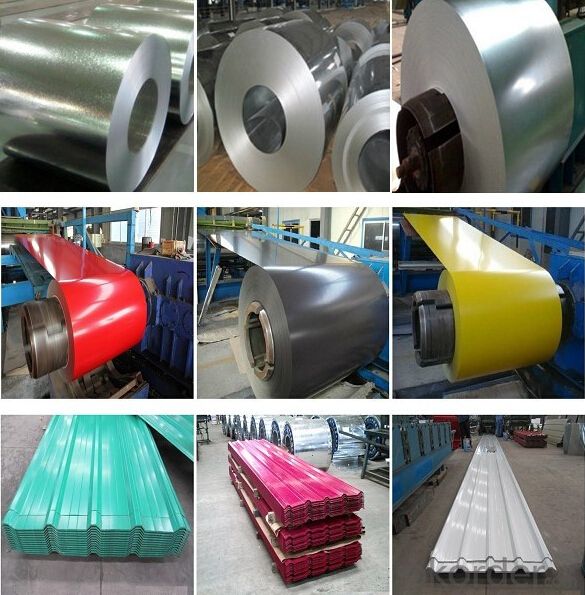

3. Aluminum Corrugated Metal Roofing Sheet Images:

4. Aluminum Sheets for Decoration Specification:

| Aluminium sheet | |||||

| Alloy No. | Thickness (mm) | Width (mm) | Length (mm) | Temper | |

| A1050,A1060, A1070,A1100 | 0.2-100 | 20-2200 | 20-8000 | O,H12,H22,H14,H16,H18, H24,H26,etc | |

| 3A21,A3003,A3105,A3004 | 0.2-100 | 20-2200 | 20-8000 | O,H14,H18,H24,etc | |

| A5052 ,A5005,A5083,A5754 | 0.2-100 | 20-2200 | 20-8000 | O,H18,H24,H32,H34,H111,H112 ,etc | |

| A6061,A6082,A6063 | 0.2-200 | 20-2200 | 20-8000 | T4,T6, T651,etc | |

| A8011 | 0.2-100 | 20-2200 | 20-8000 | O,H12,H22,H14,H16,H18,H24,H26, etc | |

5.FAQ

Q1.How long have you been in this product?

A1:More than 10 years.

Q2. What's the minium quantity(MOQ)?

A2. 5 Metric tons

Q3. How long is shipping time?

A3. 7 (ready-made products)-25 days(OEM)

Q4. How do you guarantee the quality?

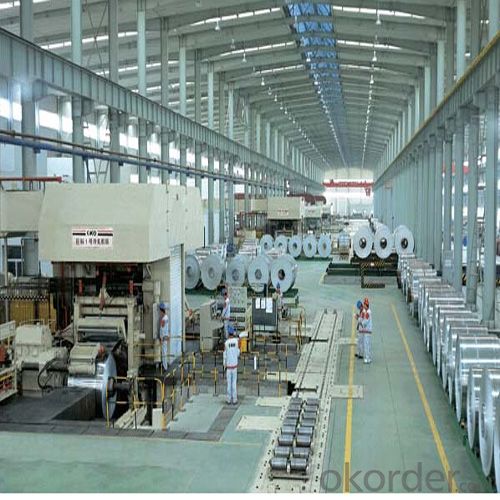

A4. 1. Cooperating and Exchaning experience with sevral quoted aluminum companies

2. Japanese and Swiss production line and skilled works (regular training and testing)

3. more than 10 years production experience.

Q5. Do you have after sale service?

A5. Yes. Any quality problem occurs within one year, pls take photoes,we will be responsible.

- Q: I was hoping someone could explain aluminum corrosion with degreasers and cleaning formulas for automotive cleaning. This starts with, where is this aluminum (wheels)?, what types of cleaners?, do cleaners cause corrosion? Any insights would be appreciated.

- stick with an automotive brand cleaner most wheels are clearcoated to prtect the finish. I use 50/50 water and simple green to clean wheels and ive been detailing 20+ years

- Q: Are aluminum sheets suitable for chemical reactors?

- Depending on the specific application and conditions, aluminum sheets can be suitable for chemical reactors. Aluminum is known for its excellent corrosion resistance, particularly when exposed to air or water, thanks to the formation of a protective oxide layer. This quality makes it appropriate for many chemical reactions involving non-aggressive substances. However, it's important to note that aluminum may not be suitable for reactors that handle highly acidic or alkaline solutions. Such solutions can corrode the oxide layer and cause the metal to degrade. Furthermore, aluminum may react with certain chemicals like strong oxidizers, halogens, or strong bases, which can compromise the integrity of the reactor. In situations where aluminum is used in chemical reactors, it is common to apply protective coatings or linings to enhance its resistance to corrosion and chemical reactions. These coatings serve as an additional barrier between the aluminum and the reactants, ensuring safe and effective operation. Ultimately, the appropriateness of using aluminum sheets for chemical reactors depends on the specific chemical reactions, operating conditions, and the required level of corrosion resistance. It is always advisable to consult with experts and consider material compatibility before selecting aluminum for such applications.

- Q: A 0.250-g sample of a magnesium-aluminum alloy dissolves completely in an excess of HCl (aq). When the liberated H2 is collected over water at 29 C and 752 torr, the volume is found to be 311 mL. The vapor pressure of water at 29 C is 30.0 torr. What is the mass percentage of aluminum in this alloy?

- Mg-Al + HCl -- MgCl2 + AlCl3 + H2 345ml gas collected over water vp water = 30torr total pressure - 30torr = pressure H2gas = 722torr = 0.95atm volume dry gas x 0.95atm = 345ml x 0.989atm volume dry gas = 359.3ml moles gas = pv/(rt) = 0.013moles 2Mg + 3Al + 10HCl -- 2MgCl2 + 2AlCl3 + 5H2 a) moles H2 = xgMg / 24.3g/mole x (5 H2 / 2Mg) = 0.103x b) moles H2 = ygAl / 27g/mole x (5H2 / 3Al) = 0.062y

- Q: What are the typical thickness options for aluminum sheets?

- Depending on the specific application and industry requirements, the thickness options for aluminum sheets vary. However, a range of thicknesses is commonly available for aluminum sheets. Some of the most frequently used thickness options include 0.025 inches (0.635 mm), 0.032 inches (0.81 mm), 0.040 inches (1.02 mm), 0.050 inches (1.27 mm), 0.063 inches (1.6 mm), 0.080 inches (2.03 mm), and 0.125 inches (3.18 mm). These thicknesses are widely utilized in industries such as aerospace, automotive, construction, and manufacturing. It's important to note that specialty aluminum sheets may offer even thicker options, tailored to the specific requirements of a given project.

- Q: Can aluminum sheet be used for electrical bus bars?

- Yes, aluminum sheet can be used for electrical bus bars. Aluminum is a commonly used material for bus bars due to its high electrical conductivity, lightweight nature, and cost-effectiveness.

- Q: This question asks for a comparison of various types of aluminum sheet materials, highlighting their unique characteristics and differences.

- <p>Aluminum sheet materials vary based on alloy composition, thickness, and surface treatment. Common types include 1000 series (99% pure aluminum), 3000 series (alloys like 3003 and 3004), 5000 series (magnesium alloys), and 6000 series (magnesium-silicon alloys). Each series has distinct properties: 1000 series is soft and ductile, 3000 series offers moderate strength and good formability, 5000 series has high strength and corrosion resistance, and 6000 series is known for its strength and excellent weldability. Thickness and temper (hardness) also affect performance, with thinner sheets being more flexible and harder tempers offering greater strength. Surface treatments like anodizing or painting can enhance appearance and corrosion resistance.</p>

- Q: If I were to make an aluminum mold and cover it with a release agent, could I cast aluminum into it? Or would the two parts fuse together? I'm trying to find an alternative to sand casting.Thank you!

- Aluminum okorder /... I use investment lost wax casting.

- Q: Could ring-pull can be transformed as aluminum sheet?

- Yes

- Q: Is it possible to use aluminum sheets for creating personalized designs or artwork?

- <p>Yes, you can use aluminum sheets to create custom designs. Aluminum is a versatile material that can be cut, shaped, and bent to create various designs. It is lightweight, durable, and resistant to corrosion, making it suitable for both indoor and outdoor applications. You can use techniques such as laser cutting, engraving, or bending to personalize aluminum sheets for your specific needs. Additionally, aluminum can be anodized or painted to achieve different colors and finishes, further enhancing the customization options.</p>

- Q: Can aluminum sheets be used in construction?

- Yes, aluminum sheets can be used in construction. Aluminum is a versatile and lightweight material that possesses several beneficial properties for construction purposes. It is corrosion-resistant, making it suitable for both indoor and outdoor applications. Aluminum sheets also have high strength-to-weight ratio, meaning they offer strength and durability while remaining relatively lightweight, which can be advantageous in construction projects where weight is a concern. Additionally, aluminum is non-toxic and highly recyclable, making it an environmentally friendly choice. These factors, combined with its aesthetic appeal and ease of fabrication, make aluminum sheets a popular choice for various construction applications such as roofing, cladding, wall panels, window frames, and more.

Send your message to us

Aluminum Corrugated Metal Roofing Sheets Toronto - Best Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t

- Supply Capability:

- 10000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords