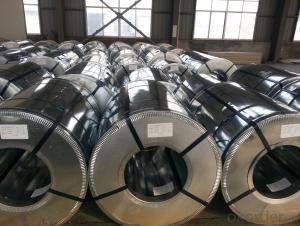

High Quality Hot Dipped Galvanized Steel Coils

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery

| Packaging Detail: | mill's standard packing,sea worthy packing,steel pallets |

| Delivery Detail: | within 15-30 days after received the deposit or the LC at sight |

Specifications

hot dipped galvanized steel coils

1.FOB:650-1000SUSD/TON

2.size:0.13-0.6mm*750-1250mm*C

3.zinc coating:50-220gsm

4.chromate

hot dipped galvanized steel coils

NAME

| PPGI |

GALVANIZED

|

GALVALUME/ALUZINC

|

CERTIFICATE | ISO9001:2008 | ||

GRADE

| CGCC CGCH CGCD1-CGCD3 CGC340-CGC570 GRADE

| SS GRADE33-80 SGCC SGCH SGCD1-SGCD3 SGC340-SGC570 SGCC DX51D | GRADE33-80 SGLCC SGLCD SGLCDD SGLC400-SGLC570 SZACC SZACH SZAC340R |

MODEL NO | 0.16MM-0.8MM*1250MM OR UNDER | (0.127-1.2*1250MM OR UNDER | 0.12MM-2MM*1250MM OR UNDER |

TYPE

|

Steel coil Steel sheets/plates Corrugated steel sheets/plates

| Steel coil Steel sheets/plates Corrugated steel sheets/plates |

Steel coil Steel sheets/plates Corrugated steel sheets/plates

|

TECHNIQUE |

Ccold rolled -galvalume /galvanized -PPGI/PPGL | Cold rolled - galvanized |

Cold rolled -galvalume /Aluzinc

|

SURFACE TREATMENT | Mini/regular/big/zero spangle, Chromate treatment /chromate-free treatment /untreated unoile/oiled, TENSION LEVELLERT SKIN PASS anti-fingerprint/un-anti-fingerprint, Coating,color

| Mini/regular/big/zero spangle, Chromate treatment /chromate-free treatment /untreated unoile/oiled, TENSION LEVELLERT SKIN PASS anti-fingerprint/un-anti-fingerprint, Coating

| |

APPLICATION | Structural use ,roofing, commercial use, household appliance, industry, family

| ||

SPECIAL APPLICATION | Wear resistant steel, high- strength - steel plate | ||

- Q: What is the tensile strength of steel coils?

- The tensile strength of steel coils can vary depending on the specific grade of steel used, but it typically ranges from 300 to 2,000 megapascals (MPa).

- Q: How long can steel coils be stored before they need to be used?

- The storage duration for steel coils can vary depending on various factors such as the type of steel, environmental conditions, and proper storage techniques. However, generally, steel coils can be stored for an extended period, ranging from several months to a few years, as long as they are stored in a controlled environment to prevent corrosion and damage.

- Q: Do any tour players use steel shafted woods? And are there any real advantages to having steel shafted woods? I have only played with one person to use steel shafted woods, he tells me thats because he cant hit it straight with graphite, however he is a very short hitter.

- Steel shafts will provide more accuracy, but they are much heavier than graphite (obviously). They have extremely low torque ratios which allows them to be more accurate. However, you need to have a very fast, controlled swing to be successful with steel shafted woods. Notice that only a few PGA Tour pros have them.

- Q: Can steel coils be used in the manufacturing of machinery and equipment?

- Machinery and equipment manufacturing can indeed utilize steel coils effectively. These coils possess remarkable versatility and contribute strength, durability, and stability to various industrial applications. They can be manipulated to assume various shapes, receive cuts, and undergo formation to generate diverse parts and components that are indispensable to the manufacturing process of machinery and equipment. Gears, shafts, frames, brackets, and other structural elements are commonly produced using steel coils. Moreover, these coils can undergo further processing to fashion specialized components like springs or fasteners. By incorporating steel coils into machinery and equipment manufacturing, the end products are guaranteed to possess exceptional quality, capable of enduring heavy loads, and boasting an extended lifespan.

- Q: How are steel coils processed and shaped for specific applications?

- Steel coils are processed and shaped for specific applications through a systematic manufacturing process. Initially, the coils are uncoiled and flattened, followed by cleaning and coating to protect against corrosion. Then, they undergo a series of shaping processes such as rolling, bending, or cutting, depending on the desired application. These processes help transform the steel coils into various forms, including sheets, plates, or strips, which can be further fabricated into specific products like automobiles, appliances, or construction materials.

- Q: my homework is a breif description on steel pipe. for plumbing/gas.please help me i dont have a clue where to start, something about the thread and where its used.Thanks,

- you can search for some web which sells steel pipe and other relative products to know more details.

- Q: How do steel coils contribute to the sustainability of construction projects?

- Steel coils contribute to the sustainability of construction projects in several ways. Firstly, steel is a highly durable and long-lasting material. Steel coils are manufactured to withstand extreme weather conditions, corrosion, and other external factors, making them ideal for construction projects that require strength and longevity. This durability reduces the need for frequent repairs and replacements, thus minimizing waste and resource consumption over time. Additionally, steel coils are recyclable. At the end of their lifespan in a construction project, steel coils can be easily and efficiently recycled. This process requires less energy compared to the production of new steel, resulting in reduced carbon emissions and environmental impact. Moreover, the recycled steel can be used in various industries, including construction, further promoting sustainability and resource conservation. Furthermore, steel coils contribute to the sustainability of construction projects by offering design flexibility. Steel is a versatile material that can be easily shaped, cut, and molded into different forms and sizes. This allows for efficient construction practices, reducing material wastage and optimizing resource utilization. Additionally, the lightweight nature of steel coils allows for ease of transportation and installation, further reducing fuel consumption and associated greenhouse gas emissions. Lastly, steel coils contribute to the sustainability of construction projects through their energy efficiency. Steel is an excellent conductor of heat and electricity, making it ideal for energy-efficient buildings. Steel coils can be used in the construction of walls, roofs, and other components that help to insulate buildings and reduce energy consumption for heating and cooling. This results in lower energy bills for the occupants and reduces the overall carbon footprint of the construction project. In conclusion, steel coils contribute to the sustainability of construction projects through their durability, recyclability, design flexibility, and energy efficiency. By using steel coils, construction projects can reduce waste, conserve resources, minimize environmental impact, and optimize energy consumption, thus promoting a more sustainable and environmentally friendly approach to construction.

- Q: What are the different methods of coating steel coils?

- There are several different methods of coating steel coils, each offering unique benefits and applications. Some of the most common methods include: 1. Hot-dip galvanizing: This process involves immersing the steel coils in a bath of molten zinc. The zinc forms a protective layer on the surface of the steel, providing excellent corrosion resistance and durability. 2. Electro-galvanizing: In this method, a layer of zinc is applied to the steel coils using an electroplating process. It provides similar corrosion resistance to hot-dip galvanizing but with a thinner coating. 3. Electro-coating (E-coating): Also known as electrodeposition, this method involves immersing the steel coils in a bath of paint or resin containing electrically charged particles. An electrical current is applied, causing the particles to adhere to the surface of the steel. E-coating provides excellent corrosion protection and is often used as a primer before applying additional coatings. 4. Powder coating: Steel coils can be coated with a dry powder paint that is electrostatically charged and then baked onto the surface. This method offers a wide range of colors, finishes, and textures, providing both aesthetic appeal and corrosion resistance. 5. Organic coatings: These coatings, such as paints or lacquers, are applied to the steel coils using various techniques like spray, roller, or dip coating. Organic coatings provide protection against corrosion, as well as offering customizable colors and finishes. Each method of coating steel coils has its advantages and is selected based on the desired level of corrosion resistance, appearance, and specific end-use requirements.

- Q: How did the growth of the steel industry influence the development of other industries?

- At least three ways: 1. Steel as a material that other industries could use to do things that couldn't be done before (for example, construction (skyscrapers, long bridges, etc.)) or could now be done at much lower cost and hence increased the size of the industry (automobiles, bearings, etc.)

- Q: Can steel coils be used in the production of furniture?

- Yes, steel coils can be used in the production of furniture. Steel coils can be used to create sturdy frames for furniture such as chairs and sofas. The coils can be shaped and welded together to provide support and durability to the furniture.

Send your message to us

High Quality Hot Dipped Galvanized Steel Coils

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords