Hot Dip Galvanized Steel Coil- Best Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hot-dip Zinc Coating Steel Building Roof Walls

1.Structure of Hot-Dip Galvanized Steel Sheet Description:

Hot-dip galvanized steel coils are available with a pure zinc coating through the hot-dip galvanizing process. It offers the economy, strength and formability of steel combined with the corrosion resistance of zinc. The hot-dip process is the process by which steel gets coated in layers of zinc to protect against rust. It is especially useful for countless outdoor and industrial applications. Production of cold formed corrugated sheets and profiles for roofing, cladding, decking, tiles, sandwich walls, rainwater protective systems, air conditioning duct as well as electrical appliances and engineering.

2.Main Features of the Hot-Dip Galvanized Steel Sheet:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent anticorrosive property

• High strength

• Good formability

• Good visual effect

3.Hot-Dip Galvanized Steel Sheet Images:

4.Hot-Dip Galvanized Steel Sheet Specification:

Standard: ASTM, JIS,EN

Grade: CS, DX51D+Z,SGCC, SS 230~550,S220GD+Z~S550GD+Z, SGC340~SGC570

Thickness: 0.1mm~5mm

Width: max 2000mm

Coil weight:3-12 MT

Coil ID:508/610mm

Surface structure: zero spangle, regular spangle or minimum spangle

Surface treatment: Chromate treatment, Oiled/dry, skinpassed/non-skinpassed

Packing: Standard seaworthy export package

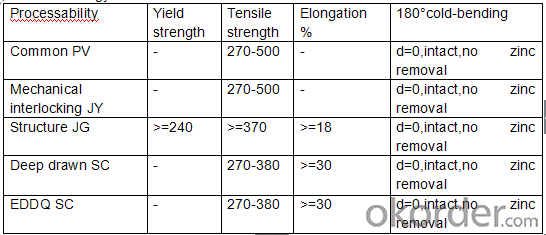

Technology test results:

5.FAQ of Hot-Dip Galvanized Steel Sheet:

We have organized several common questions for our clients,may help you sincerely:

1.How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

2.How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

3. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-30 days, but the shipment will depend on the vessel situation.

- Q: How do steel coil manufacturers stay updated with industry trends?

- Steel coil manufacturers utilize various methods to stay informed about industry trends: 1. Attending industry conferences and trade shows allows manufacturers to connect with other professionals, attend seminars and presentations, and learn about the latest trends and innovations in the steel coil industry. 2. Subscribing to industry publications and magazines provides manufacturers with regular updates on trends, market insights, and technological advancements in the steel coil industry. These publications often feature articles and interviews with experts, delivering valuable information to stay updated. 3. Actively participating in online forums, discussion boards, and social media groups dedicated to steel coil manufacturing helps manufacturers stay connected with the industry. These platforms allow them to engage with peers, share knowledge, ask questions, and stay updated on the latest trends. 4. Maintaining close relationships with suppliers and customers enables manufacturers to gain insights into changing market demands, new product requirements, and emerging trends. Suppliers and customers often share information about industry trends and advancements that assist manufacturers in adapting their processes accordingly. 5. Investing in continuous education and training programs for employees ensures that the workforce remains updated on the latest industry trends, technological advancements, and best practices. Prioritizing employee development equips manufacturers with the skills and knowledge necessary to stay ahead of the curve. 6. Allocating resources for research and development activities allows steel coil manufacturers to explore new materials, manufacturing techniques, and technologies. By investing in R&D, manufacturers can stay at the forefront of industry trends and develop innovative solutions that meet evolving customer demands. 7. Staying updated with government regulations, industry standards, and certifications that impact the steel coil industry is crucial. Compliance with these regulations often requires manufacturers to adopt new practices, technologies, or materials, ensuring that they remain up to date with the latest trends and requirements. By actively engaging in these activities, steel coil manufacturers can stay informed about industry trends, emerging technologies, and market demands. This enables them to adapt their processes, products, and strategies to remain competitive and meet the evolving needs of their customers.

- Q: What are the different types of steel coil cutting methods?

- There are several different types of steel coil cutting methods, including shearing, slitting, and laser cutting. Shearing involves using a straight blade to cut through the coil, while slitting involves using circular blades to make multiple cuts. Laser cutting is a more precise method that uses a laser beam to cut through the coil. Each method has its advantages and is chosen based on the specific requirements of the project.

- Q: How does coil slitting work?

- Coil slitting is a process used in manufacturing industries to cut large coils of material, such as metal, into narrower strips of desired widths. The coil is unwound and passed through a set of circular blades that make precise cuts along the length of the coil. The blades can be adjusted to the desired width, and the process continues until the entire coil is slit into multiple smaller coils or strips.

- Q: I am looking to weld some stainless steel using stainless electrodes. I was told that the arc welder needs to be able to run in DC in order to be able to weld stainless steel. Is this true? Or can you weld stainless steel with stainless electrodes with AC also?

- Stainless Steel Stick Welding

- Q: Suppose that the hardness of steel is uniformly distributed, taking on values between 50 and 80 on the Rockwell B scale.Compute the probability that the hardness of a randomly selected steel specimen is less than 60. a..462b..333c..500d.2e..750 Question 8 Refer to question 7. Compute the probability that the hardness of a randomly selected steel specimen is between 70 and 75.a..167b..500c..063d..100e..

- Suppose that the hardness of steel is uniformly distributed, taking on values between 50 and 80 on the Rockwell B scale. That would be... f(x) = 1/(80 - 50), 50 ≤ x ≤ 80 . . . . . 0 elsewhere Consider this following problem.. Compute the probability that the hardness of a randomly selected steel specimen is less than 60. Here, we have... P(x 60) Oh! Know that the mean and the standard deviation of the uniform distribution function are... ? = (a + b)/2 σ = (a - b)?/12 You should get... ? = 65 σ = 75 Now... P(z (60 - 65)/75) = P(z -0.07) Hence, you should get around 0.462. Good luck!

- Q: How do steel coils contribute to strength and stability in structures?

- Steel coils are vital components in numerous structures due to their significant impact on strength and stability. The exceptional strength of steel itself makes it renowned, as it can resist large amounts of tension without breaking or deforming. When steel is shaped into coils, its strength is further enhanced by evenly distributing the load across the entire structure. This even distribution of force prevents localized stress concentrations, enabling the structure to withstand heavy loads and external pressures more effectively. Furthermore, steel coils provide stability to structures by offering rigidity and resistance against deformation. Steel is known for its stiffness, preventing excessive flexing or bending under loads. The tightly wound coils create a robust and compact structure that can efficiently resist dynamic forces like wind, earthquakes, or vibrations. This resistance to deformation minimizes potential damage, ensuring the structure's stability and integrity. Moreover, steel coils also contribute to the durability and longevity of structures. Steel exhibits remarkable durability, being highly resistant to corrosion, rust, and deterioration over time. This longevity ensures that structures built with steel coils can remain strong and stable for extended periods, requiring minimal maintenance or repairs. Additionally, steel coils offer versatility in design and construction. The ability to shape steel into various coil sizes and configurations allows for customization based on specific structural requirements. Architects and engineers can utilize steel coils to create complex structures while maintaining their strength and stability. This versatility allows for innovative and efficient design solutions, making steel coils the preferred choice in many construction projects. In conclusion, steel coils play a crucial role in enhancing the strength and stability of structures. The inherent strength of steel, combined with the unique design of coils, provides structures with the necessary rigidity, resistance to deformation, and durability. Additionally, the versatility of steel coils allows for customization and innovative design solutions. Overall, steel coils significantly contribute to the overall integrity and longevity of structures, making them an essential component in the construction industry.

- Q: What is the role of steel coils in the production of appliances?

- The role of steel coils in the production of appliances is to provide a strong and durable material for the construction of various components and structures. Steel coils are commonly used to manufacture appliance parts such as panels, frames, cabinets, and internal components. The high strength and versatility of steel make it ideal for withstanding the stress and demands of everyday appliance use. Additionally, steel coils can be shaped, molded, and welded to create customized designs and configurations, ensuring the appliances are both functional and aesthetically pleasing.

- Q: I have a job where I'm required to wear ANSI certified steel toed boots or shoes(so long as its ANSI). Thing is, I'm a vegan. I do NOT want to buy leather, and I will go to great lengths to buy a non leather shoe/boot I can wear on the job! I AM currently borrowing my dad's leather ANSI boots, but would very much love to be able to rock a pair of cruelty free boots/shoes on the job!It does not have to be certified vegan just all man-made materials and no leather/sued and other such stuff where animals have to die. It would make me no better than the massive slaughterhouse industries and such. Valueing money of ver live/morals. I don't want one of the first things I need to do in my manufacturing job is compromising my morals. :3So if you know of an ANSI vegan friendly boot brand PLEASE TELL ME! *gets on knees begging*Money isn't really an option for me, I'll just continue borrowing my dad's boots till I save up enough!Thanks in advance! :D

- Sears okorder /

- Q: How do steel coils contribute to the manufacturing of HVAC systems?

- The manufacturing of HVAC systems heavily relies on steel coils, which have a critical role. These coils typically consist of high-quality steel, known for its exceptional strength, durability, and resistance to heat. Heat exchangers are one of the primary applications of steel coils in HVAC systems. These exchangers play a vital role in transferring heat between different mediums, usually air and a refrigerant. In HVAC systems, steel coils are employed in both the evaporator and condenser coils. The evaporator coil absorbs heat from the indoor air, while the condenser coil releases heat to the external environment. These coils are designed with numerous coiled tubes connected by fins. The use of steel in their construction ensures their ability to withstand high pressure and resist corrosion, guaranteeing the long-term reliability and efficiency of the HVAC system. Steel coils also contribute to the overall structural integrity of HVAC systems. They are commonly utilized in the fabrication of ductwork, responsible for distributing conditioned air throughout a building. The strength and rigidity of steel coils enable the ductwork to maintain its shape and structural integrity under various conditions, including high air pressure and temperature fluctuations. Additionally, steel coils are frequently involved in the fabrication of HVAC system cabinets and enclosures. These cabinets house several system components, including compressors, fans, and control panels. The robustness of steel coils ensures that the cabinets can withstand external forces, protect the internal components, and provide a secure housing for the entire HVAC system. To summarize, steel coils are crucial components in the manufacturing of HVAC systems. Their strength, durability, and heat resistance make them ideal for applications such as heat exchangers, ductwork, cabinets, and enclosures. By incorporating steel coils, HVAC manufacturers can produce systems that efficiently regulate temperature, enhance indoor air quality, and provide comfort in various residential, commercial, and industrial settings.

- Q: What are the different types of steel coil handling devices?

- There are various types of steel coil handling devices, including coil lifters, coil tongs, coil hooks, coil grabs, and coil carriages.

Send your message to us

Hot Dip Galvanized Steel Coil- Best Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords