Hot-dip Zinc Coating Steel Building Roof Walls

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1212123 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Hot-Dip Galvanized Steel Sheet Description:

Hot-dip galvanized steel coils are available with a pure zinc coating through the hot-dip galvanizing process. It offers the economy, strength and formability of steel combined with the corrosion resistance of zinc. The hot-dip process is the process by which steel gets coated in layers of zinc to protect against rust. It is especially useful for countless outdoor and industrial applications. Production of cold formed corrugated sheets and profiles for roofing, cladding, decking, tiles, sandwich walls, rainwater protective systems, air conditioning duct as well as electrical appliances and engineering.

2.Main Features of the Hot-Dip Galvanized Steel Sheet:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent anticorrosive property

• High strength

• Good formability

• Good visual effect

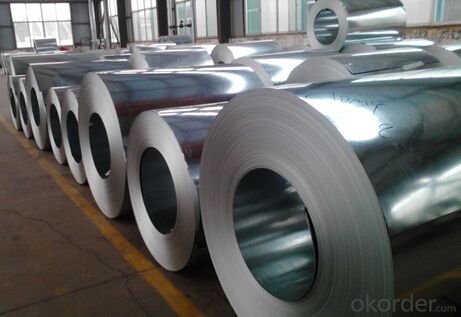

3.Hot-Dip Galvanized Steel Sheet Images

2.Hot-Dip Galvanized Steel Sheet Specification

Standard: ASTM, JIS,EN

Grade: CS, DX51D+Z,SGCC, SS 230~550,S220GD+Z~S550GD+Z, SGC340~SGC570

Thickness: 0.1mm~5mm

Width: max 2000mm

Coil weight:3-12 MT

Coil ID:508/610mm

Surface structure: zero spangle, regular spangle or minimum spangle

Surface treatment: Chromate treatment, Oiled/dry, skinpassed/non-skinpassed

Packing: Standard seaworthy export package

Technology test results:

Processability | Yield strength | Tensile strength | Elongation % | 180°cold-bending |

Common PV | - | 270-500 | - | d=0,intact,no zinc removal |

Mechanical interlocking JY | - | 270-500 | - | d=0,intact,no zinc removal |

Structure JG | >=240 | >=370 | >=18 | d=0,intact,no zinc removal |

Deep drawn SC | - | 270-380 | >=30 | d=0,intact,no zinc removal |

EDDQ SC | - | 270-380 | >=30 | d=0,intact,no zinc removal |

5.FAQ of Hot-Dip Galvanized Steel Sheet

We have organized several common questions for our clients,may help you sincerely:

1.How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

2.How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

3. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-30 days, but the shipment will depend on the vessel situation.

- Q: How are steel coils used in the manufacturing of electrical transformers?

- Steel coils are used in the manufacturing of electrical transformers as they provide a strong and durable core for the transformer. The coils are typically made of high-grade electrical steel, which has low electrical resistance and high magnetic permeability. These properties allow the coils to efficiently conduct and transform electrical energy, ensuring the proper functioning of the transformer.

- Q: What are the challenges in coil slitting for narrow strip widths?

- Coil slitting for narrow strip widths presents a number of challenges. One key challenge is the need to maintain precision and accuracy throughout the slitting process. Even the smallest misalignment or deviation can result in significant defects or inconsistencies in the final product. Therefore, it is important to calibrate and adjust the slitting equipment carefully to ensure accurate cuts. Another challenge is the risk of material damage or deformation during slitting. Narrow strip widths are more susceptible to distortion, wrinkling, or edge cracking, especially if the material is not handled or supported properly. To minimize potential damage, it is necessary to feed the material smoothly through the slitting machine and control the tension effectively. In addition, handling and transporting slit coils can be challenging due to their narrow width. These coils are prone to bending, twisting, or telescoping, which can cause difficulties in stacking, storage, or transportation. To maintain the shape and integrity of the coils, proper packaging and handling techniques must be employed throughout the supply chain. Furthermore, narrow strip widths often require more frequent blade changes during slitting. This adds complexity and time to the setup and maintenance process, as the blades need to be carefully selected and replaced for optimal cutting results. Skilled technicians are crucial for efficiently and effectively handling these blade changes. Overall, while coil slitting for narrow strip widths offers cost savings and increased material utilization, it also comes with challenges that need to be addressed. These challenges include maintaining accuracy, preventing material damage, ensuring proper handling and transportation, and managing blade changes effectively. By understanding and addressing these challenges, manufacturers can optimize their coil slitting operations and produce high-quality narrow strip products.

- Q: What are the dimensions of steel coils used in the automotive industry?

- Steel coils used in the automotive industry come in various dimensions, which are determined by the specific application and requirements. Normally, the thickness of these coils falls between 0.5mm and 3mm, while the width ranges from 500mm to 2000mm. The length of the coils is subject to variation, depending on the production process and customer specifications. Furthermore, the weight of the coils can range from a few hundred kilograms to several tons. It is worth mentioning that these dimensions serve as general guidelines and may differ based on the particular needs of the automotive manufacturer.

- Q: What are the different methods of perforating steel coils?

- There are several methods of perforating steel coils, including rotary punch, laser cutting, and stamping. Each method offers its own advantages and is chosen based on factors such as the desired hole size, material thickness, and production volume. Rotary punch involves using a rotating tool to create holes in the steel coil, while laser cutting uses a high-powered laser beam. Stamping, on the other hand, involves using a die and press to create holes by applying pressure to the steel coil.

- Q: How are steel coils used in the manufacturing of braking systems?

- Steel coils are used in the manufacturing of braking systems to create brake pads and other components that require heat resistance and durability. The steel coils are shaped and processed to form brake pads, which provide friction against the rotor to slow down or stop the vehicle. Additionally, steel coils are also used in the production of brake calipers, rotors, and other parts that ensure efficient and reliable braking performance.

- Q: What are the common coil diameter and weight combinations available for steel coils?

- The available combinations of coil diameter and weight for steel coils vary depending on specific requirements and industry standards. However, the market offers commonly used combinations that are widely accessible. Coil diameter commonly ranges from 24 inches (610 mm) to 72 inches (1829 mm). These sizes are often utilized in industries such as automotive, construction, and manufacturing. Coil weight varies significantly based on the steel type and thickness. In the case of hot-rolled coils, the weight typically falls between 5 to 30 metric tons. For cold-rolled coils, the weight usually ranges from 2 to 20 metric tons. Heavier coils are commonly applied in heavy-duty situations, while lighter coils are preferred for delicate or precise applications. It's important to remember that these are general guidelines, and the actual combinations of coil diameter and weight can be customized to meet a customer's specific needs. Different manufacturers and suppliers offer a wide range of options to accommodate various industry requirements. Therefore, it is advisable to consult with the specific supplier to determine the available coil diameter and weight combinations that best suit your application.

- Q: I'm just wondering what the best steel would be for an edc/hunting knife that could put up with alot of abuse.

- D2 and O2 steels are nice. They are expensive, but hold an edge extremely well. S30V is nice also. It's a more stain-resistant steel that holds an edge very well. For outdoor hiking/camping knives, it's tough to beat good old 1095 carbon steel. Sure it will rust, but it's tough as nails, not brittle, holds an edge pretty well, and easy to sharpen...and it's pretty cheap. Other steels, AUS8 is an ok cheap steel. It's stain resistant and cheap. AUS6 isn't worth the time or effort. Buck knives does an excellent job of heat treating 420 stainless to become very hard. Their knives are excellent considering 420 stainless is typically soft steel.

- Q: What are the common coil processing methods?

- Some common coil processing methods include slitting, cut-to-length, leveling, and blanking. These methods are used to transform large coils of metal into smaller, more manageable sheets or strips for further manufacturing processes.

- Q: Steel being my favorite type, I just picked up Heart Gold today, my gf got Soul Silver...I was wondering which steel types are available and somewhat easily obtainable in HG (and/or what is the earliest steel type I can get?)

- Magnemite is the first steel type you can obtain. Get it by going to the Safari Zone in the mountain area. Magnetons are also found there. You can also evolve a Pineco into a Forretress. You can find Pineco by headbutting trees. Unfortunately, those are the only easy-to-find steels before the Pokemon league. Afterwards, you can obtain a Bronzor, Metagross, Steelix*, and Scizor*. Your girlfriend can trade you a Skarmory as well. Of all the ones listed, Forretress is probably the easiest to obtain, but Metagross is the best. I hope that helped. Contact me if you want more info! *Steelix and Scizor are obtained by trading an Onix or Scyther while holding a Metal Coat. Technically, you can get them before the Elite Four. However, you would need a friend to give you their Metal Coat, or get lucky and find one on a wild Pokemon, becaue the only one you get in-game is obtained after you beat the Elite Four.

- Q: Are steel coils used in the oil and gas industry?

- Yes, steel coils are commonly used in the oil and gas industry for various applications such as pipeline construction, storage tanks, and drilling equipment. The strength, durability, and corrosion resistance of steel make it an ideal material for handling the demanding conditions in this industry.

Send your message to us

Hot-dip Zinc Coating Steel Building Roof Walls

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1212123 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords