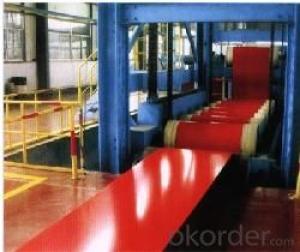

Prepainted Steel Coils, Hot-dipped galvanized, RAL System, with good corrosion resistance

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

Specifications:

1. Standard: AISI,ASTM,BS,DIN,GB,JIS,ASTM,JIS,GB

2. Steel Grade: DX51D, SGCC, SGCH, SPCC,SPCD,DC01,ST12,ST13,Q195,08AL

3. Thickness: 0.13-0.5mm

4. Width: 600-1250mm

5. Length: up to The Thickness or as require

6.Spangle: Zero,Mini,Regular,Big,Skin Pass

7.Audited Certificates:BV, SGS, ISO,CIQ

8.Zinc Coating:40g-200g

9.surface: chromated ,dry/oiled,Cr3 treated anti-finger

10.Package: standard exporting package (or as required)

11.ID: 508/610mm

| commodity | Color Coated Steel Coil (PPGI/ PPGL) |

| Techinical Standard: | JIS G3302-1998, EN10142/10137, ASTM A653 |

| grade | TSGCC, TDX51D / TDX52D / TS250, 280GD |

| Types: | For general / drawing use |

| Base metal | galvanized, galvalume, cold rolled steel |

| Thickness | 0.14-1.0mm(0.16-0.8mm is the most advantage thickness) |

| Width | 610/724/820/914/1000/1200/1219/1220/1250mm |

| Type of coating: | PE, SMP, PVDF |

| Zinc coating | Z60-150g/m2 or AZ40-100g/m2 |

| Top painting: | 5 mic. Primer + 15 mc. R. M. P. |

| Back painting: | 5-7 mic. EP |

| Color: | According to RAL standard |

| ID coil | 508mm / 610mm |

| Coil weight: | 4--8MT |

| Package: | Properly packed for ocean freight exportation in 20' ' containers |

| Application: | Industrial panels, roofing and siding for painting / automobile |

| Price terms | FOB, CFR, CIF |

| Payment terms | 20%TT in advance+80% TT or irrevocable 80%L/C at sight |

| delivery time | 25 days after recepit of 20% TT |

| Remarks | Insurance is all risks |

| MTC 3.1 will be handed on with shipping documents | |

| We accept SGS certificatation test |

1, Mill/factory supply,Quality protection,4 Galvanized steel lines keep runing.

2, Competitive price with best quality and service

3, Nearest sea port, Convenient transportation,Efficient service team online for 24 hours

4, More than 7 years Export Experiences,More than 50 countries customers

5. Delivery time: Within 25-35 days after the receipt of L/C or according to customer's requirement.

- Q: How are steel coils used in the production of HVAC ductwork?

- Steel coils are commonly used in the production of HVAC ductwork due to their durability and strength. The coils are typically made of galvanized steel, which provides protection against corrosion and extends the lifespan of the ductwork. The manufacturing process begins with the steel coils being unrolled and cut into the desired length. The coils are then fed through a machine that shapes the steel into a rectangular or round duct form. This shaping process can be done using various techniques such as roll forming or press braking. Once the steel has been formed into the desired duct shape, it is then joined together using various methods such as welding or locking mechanisms. Welding is often used for rectangular ducts, while locking mechanisms like snap locks or Pittsburgh seams are commonly used for round ducts. These joining techniques ensure that the ductwork is secure and airtight. After the ductwork has been assembled, it may undergo additional processes such as insulation or lining. Insulation helps to reduce heat loss or gain, while lining can improve the acoustic properties of the ductwork. These additional steps are often done to meet specific requirements or regulations. Overall, steel coils play a crucial role in the production of HVAC ductwork as they provide strength, durability, and protection against corrosion. The versatility of steel allows for various shapes and sizes of ductwork to be fabricated, making it a popular choice for HVAC systems.

- Q: How are steel coils used in the manufacturing of automotive body panels?

- Steel coils are used in the manufacturing of automotive body panels by being processed and shaped into the desired form through techniques like stamping or roll forming. These coils provide the raw material for creating strong and durable body panels, ensuring the vehicle's structural integrity and safety.

- Q: What are the dimensions of steel coils used in the industrial machinery industry?

- The dimensions of steel coils used in the industrial machinery industry can vary depending on the specific application and requirements. However, generally speaking, steel coils used in this industry typically have a width ranging from 600 to 2,000 millimeters (24 to 79 inches) and a weight ranging from 2 to 25 metric tons (4,400 to 55,100 pounds). The inner diameter of the coil, known as the core, can range from 508 to 762 millimeters (20 to 30 inches). Additionally, the thickness of the steel coil can range from 0.4 to 25 millimeters (0.016 to 0.98 inches). These dimensions may be subject to variations based on the specific needs and specifications of the machinery being manufactured or used in the industrial machinery industry.

- Q: i have a computer chair where the metal part that attachs the top part to the bottom with wheels has cracked around half of the assembly. my dad said it might be able to be repaired with jb weld. can jb weld fix it? how strong is jb weld? is it as strong as steel?

- Not a chance. Stresses that are strong enough to crack solid steel would snap JB weld like a matchstick! JB is NOT a substitute for actual welding. Steel is more than 20 times stronger; or in other words, JB is 20 times weaker than the steel in your chair. JB is good for applications where the parts to be joined aren't constantly going to be under stress. For wood or plastics it works OK, for steel, not so much. Your best bet is to take the chair to a professional welding shop. If they want to charge you more than $15-$20; go somewhere else, they could weld that in less than a minute.

- Q: I am buying a knife for my future husband for his wedding gift and I was wondering what is better carbon steel or stainless steel?

- carbon steel is my choice. googlecarbon steel vs stainless steel knives for more info. If you buy stainless make sure it is an alloy that will hold an edge..many a shiny knife is just a dull dud. Carbon blades don't rust unless they are left laying in the wet. I was having this conversation with a Friend once. So I took his knife and struck his knifes edge against mine with a light blow.. His had a 1/16 dent in it, mine not even a mark on it. I assume this is not a kitchen knife.

- Q: Which movie is better and why?I say Man of Steel!

- Captain America: The First Avenger -- Mostly because it was a rousing, entertaining, old-school adventure film, plus it was true to the character of Steve Rogers/Captain America. Man of Steel, IMO, had a poor script, tinkered way too much with one of the great superhero origin stories and was not at all true to the character. Historically Superman has always been a symbol of heroism, proud, strong, beaming. But what we got in that movie was an utterly cheerless, dour automaton devoid of any kind of charisma or presence. I don't know who that boring, depressed dude who looked like Superman was in that movie, but he most certainly wasn't Superman.

- Q: They both sell the same thingIf prices are to high companies won't by the steelIf prices are to low then the steel company won't earn enoughWhy are some steel companies more successful than others

- Steel is a global commodity. There is some variety in product (flat rolled, tubing, etc), but basically the same product worldwide. Cost to the customer includes shipping of a very heavy product. Inputs are also heavy and costly to ship. Inputs: - Coal - Iron Ore. Some firms have the ability to recycle old steel, a competitive advantage. - Energy (very energy intensive industry) - Labor - Machinery. A new blast furnace is more efficient than 50 years old. So the most profitable steel firms have some of these characteristics: - Proximity to raw materials - Proximity to customers - Access to cheaper means of transportation; rail and sea - Newer machinery - Cheaper labor force - Reasonable cost for electricity and fuel for furnaces

- Q: How are steel coils used in the production of electrical enclosures?

- Steel coils are used in the production of electrical enclosures as they are formed and shaped into various components such as panels, frames, and doors. These coils are typically cut, stamped, and bent to the required dimensions, providing the necessary strength and durability for the enclosures. Additionally, steel coils can be coated or painted to enhance their resistance to corrosion and improve the overall aesthetics of the electrical enclosure.

- Q: What are the different types of steel coil storage containers?

- There are several types of steel coil storage containers, including coil racks, coil cradles, coil saddles, coil cassettes, coil pallets, and coil cones. These containers are designed to safely store and transport steel coils, providing support and stability to prevent damage or shifting during handling and storage.

- Q: How are steel coils inspected?

- Steel coils are inspected using various methods such as visual inspection, ultrasonic testing, magnetic particle inspection, and eddy current testing. These techniques help identify any defects, irregularities, or damages in the steel coils, ensuring their quality and suitability for further processing or use.

Send your message to us

Prepainted Steel Coils, Hot-dipped galvanized, RAL System, with good corrosion resistance

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords