Best Quality for Hot Dip Galvanized Steel Coil-Minimum Spangle

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50mt m.t.

- Supply Capability:

- 5000 tons per month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

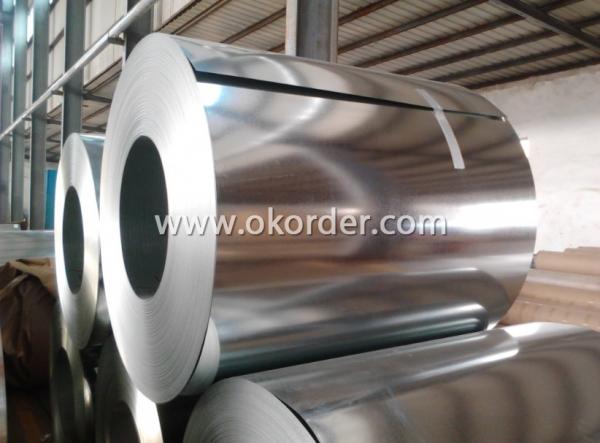

General Information of Hot Dip Galvanized Steel Coil

Hot-dip galvanized steel coils are available with a pure zinc coating through the hot-dip galvanizing process. It offers the economy, strength and formability of steel combined with the corrosion resistance of zinc. The hot-dip process is the process by which steel gets coated in layers of zinc to protect against rust. It is especially useful for countless outdoor and industrial applications.

Specification of Hot Dip Galvanized Steel Coil:

1. Thickness: 0.15-1.2mm

2. Width: 800mm-1250mm

3. Internal Diameter: 508mm/610mm

4. Coil Weight: 3-12MT

5. Quality: commercial and structural quality

6. Surface Treatment: regular & minimum spangle, zero spangle, oiled & dry , chromated , non-skin pass ,skin pass

7. Standard: JIS G 3302, ASTM A 653M, EN 10327

8. Steel Grade: SGCC, CS, FS, SS, LFQ, DX51D+Z , S280GD

Technical Data of Hot Dip Galvanized Steel Coil

Chemical Composition | C | Si | Mn | P | S |

0.04-0.06% | 0.01-0.03% | 0.18-0.22% | 0.014-0.016% | 0.006%-0.009% |

Technical Data | |

Yield Strength | (Mpa) 280-320 |

Tensile Strength | (Mpa) 340-390 |

Elongation | 20%-30% |

Out-of-square | not exceed 1% Flatness |

Bow | 15mmmax |

Edge Wave | 9mmmax |

Centre Buckle | 8mmmax |

Bending At 180 Degree | No crack, purling and fraction |

Application of Hot Dip Galvanized Steel Coil

It can be widely used in transportation, light industry, civil usage and farming. It is also the perfect building material in construction for making roofing tile, steel profiles for wall partition, T-bar, studs, fireproof door, air conditioning duct and home appliance.

Package of Hot Dip Galvanized Steel Coil

Full wrapped with anti-damped paper inside, iron sheet wrapped outside, and bundled by iron strips

- Q: What are the different coil packaging materials used for steel coils?

- Different materials are used for packaging steel coils, each with its own unique properties and benefits. Some of the most commonly used materials are as follows: 1. Stretch film is a flexible material that tightly wraps around the coil, providing protection against dust, moisture, and scratches. 2. Steel strapping is a strong and durable option that ensures the coils remain tightly bound during transportation or storage, thanks to its high tensile strength and resistance to breakage. 3. Plastic strapping, on the other hand, is a lightweight and cost-effective alternative to steel strapping. It offers good shock absorption and is resistant to rust and corrosion, making it suitable for smaller or lighter steel coils. 4. Paperboard is an environmentally friendly packaging material that provides a protective layer against dust and minor impacts. It also allows for slight breathability to prevent moisture buildup. 5. Wooden crates are commonly used for large or heavy steel coils, as they offer sturdy support and protection during handling, transportation, or storage. 6. Corrugated cardboard is a versatile and lightweight material suitable for smaller steel coils. It provides cushioning and protection against minor impacts, and it is easily recyclable. The choice of packaging material for steel coils depends on factors such as coil size and weight, transportation requirements, and the desired level of protection. Each material has its own advantages and should be selected based on the specific needs of the steel coil packaging.

- Q: What are the different types of steel coil handling systems?

- There are several different types of steel coil handling systems, including coil upenders, coil cradles, coil transfer cars, coil tilters, and coil grabbers.

- Q: So here's the deal:I recently bought McCann's Instant Steel-Cut Oatmeal, and I'm wondering about any possible nutritional differences between the instant and regular stove-top. In case you haven't seen it, instant steel-cut comes in individual packets and is cooked only by adding boiling water, the same as instant rolled oatmeal (i.e. Quaker).When I asked about instant vs. stove-top rolled oats, my doctor said there are no significant nutritional differences, but since the main health appeal of steel-cut is the coarse grain, it doesn't seem possible for the finer ground instant to be as nutritious.I can't find much info about this, so any help is appreciated!

- The rationale for consuming steel cut oats rather than rolled oats (beyond the fact that the former taste really good) is the lower glycemic index. It is my understanding that in the rolled oat category, it is better to eat the long-cooking variety rather the instant for the improved fiber load and lower glycemic index. While I do not understand exactly how instant steel cut oats are processed and how much the glycemic index is affected by processing, it is safe to assume that the old unprocessed steel cut oats are still best. I always prepare 4-6 servings of the steel cut oats at one time and warm up a serving when needed to avoid having to wait 30 minutes to cook them. My rule of thumb: the less processing for any food product, the better it is for me.

- Q: Ok, I need two negative facts about steel wheels and two for aluminum wheels. im designing a wheel for a project in design and draw for production class. Also if you find a web site that you got the info from plz refrence it i need to write down the source of the info, but if you can't its ok. Thanks

- Negative facts for steel wheels: (1) Not as many style choices as aluminum. (2) Rust easily even when painted or powder coated, due to rock chips. (3) Heaver than aluminum, as far as fuel economy. Negative facts for aluminum wheels: (1) More sensitive to proper torquing of lug nuts. IE torque must be checked more often. (2) Susceptible to impact damage from road hazards much more than steel. (3) Need constant attention to prevent oxidation. Are these what you are looking for? I hope so. Wingman

- Q: What are the challenges faced during steel coil processing?

- Some of the challenges faced during steel coil processing include ensuring proper alignment and feeding of the coils into the machinery, handling the heavy weight and size of the coils, managing the high temperatures involved in processing, preventing surface defects or damage to the steel, maintaining consistent quality throughout the process, and minimizing material waste and scrap.

- Q: I'm trying to buy a Survival,tactical knife but don't know what steel is better

- Depends on the grade of metal and how it is tempered. Poor grade or any steel is worthless. Poor temper on quality steel is worthless. I have several 440 Stainless Steel knives that hold a edge very well. But I to have several carbon steel knives that also hold a fine edge. It pretty much boils down to you get what you pay for, top quality don’t come cheap. I prefer name brands like Puma, Buck, S.O.G, Gerber and Old Timer. These brands have never failed me yet. A $5.00 knife is a $5.00 knife , where as S.O.G, and Puma can run you a couple hundred dollars easy. But I have field dressed 5 deer and that was cutting through the pelvic bone of all 5 deer before dulling my Puma, but back in 1978 that puppy cost me $65.00. For Tactical knives S.O.G is my favorite. Don’t be fooled by the cheesy Rambow survival knives, remember the key word is survival so your life may some day rest on the quality knife you buy. It don’t have to have a cheap compass or hollow handle to hold fish hooks and matches. It needs to be a knife you can bet your life on. Look at the knives that the military special forces use today S.O.G makes up most of them Either the S.O.G “Seal pup” used by the Army Rangers or the full sizes “Seal” used by other military special forces teams. ( my son was a trainer for the U S Army Rangers and he was issued a S.O.G Seal Pup) I would suggest you invest in a high quality knife, you can always make up a small survival kit using quality hooks and matches and a quality compass. Remember your life may some day rest on what you invest in. You would not buy cheesy health insurance, now would you? D58 Hunting with Rifle, Pistol, Muzzle loader and Bow for over 3 decades. Reloading Rifle, Pistol and shotgun for over 3 decades.

- Q: How are steel coils used in the production of industrial machinery?

- Steel coils are used in the production of industrial machinery as they provide a strong and durable material for various components. These coils are often shaped and cut to specific sizes to create parts such as gears, shafts, and frames, which are essential for the functioning of machinery. The high strength and flexibility of steel coils make them ideal for withstanding heavy loads and harsh operating conditions, ensuring the reliability and longevity of industrial machinery.

- Q: I have a bottle like this* Can u make hot chocolate in it. Can i heat it.I wanna take hot Chocolate to school

- Hot drinks only do well in an insulated thermos. Thermos's were designed for hot drinks. This stainless steel water bottle is not a thermos. You could put hot chocolate or coffee in the water bottle, but you'll burn your hand if you touch it. And, it will cool down very quickly.

- Q: I want to purchase a set of knives made of carbon steel and want to be able to store them on a magnetic knife strip for handy access, I just wasn't sure if this alloy would stick to a magnet????Thanks

- Carbon steel knives will stick to a magnet. Stainless steel may not.

- Q: How are steel coils inspected for quality control purposes?

- Steel coils are inspected for quality control purposes through various methods such as visual inspection, dimensional checks, and non-destructive testing techniques. Visual inspection involves examining the surface of the coil for any defects or irregularities. Dimensional checks are conducted to ensure that the coil meets the specified thickness, width, and length requirements. Non-destructive testing techniques like ultrasonic testing or magnetic particle inspection are used to detect internal flaws or defects in the steel coil. These inspection methods help ensure that the steel coils meet the desired quality standards before they are used in various applications.

1. Manufacturer Overview

| Location | Zhejiang, China |

| Year Established | 1999 |

| Annual Output Value | US$1 Million - US$2.5 Million |

| Main Markets | Europe; Africa; Mid East; Southeast Asia |

| Company Certifications | ISO9001;ISO14001 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai Port |

| Export Percentage | 41% - 50% |

| No.of Employees in Trade Department | 50-80 |

| Language Spoken: | Chinese, English |

| b) Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | 5 |

| Contract Manufacturing | OEM Service Offered |

| Product Price Range | Average |

Send your message to us

Best Quality for Hot Dip Galvanized Steel Coil-Minimum Spangle

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50mt m.t.

- Supply Capability:

- 5000 tons per month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords