Prepainted Aluzinc Steel Coil-ASTM A755M

- Loading Port:

- China Main Port

- Payment Terms:

- T/T or L/C

- Min Order Qty:

- 50mt m.t.

- Supply Capability:

- 100,000 mt m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

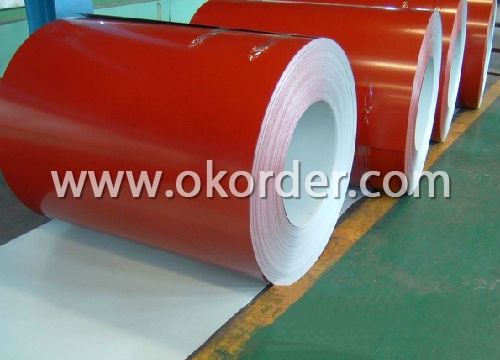

General Information Of Prepainted Aluzinc Steel

With GL as base metal, after pretreatment (degrease and chemical treatment) and liquid dope with several layers of color, then after firing and cooling, finally the plate steel is called pre-painted aluzinc steel. Pre-painted aluzinc steel is good capable of decoration, molding, corrosion resistance. It generally displays superior workability, durability and weather resistance.

Thickness 0.23-1.2mm (BMT) |

Zinc Coating 80-275g/m2 |

Color According to RAL color fan |

Internal Diameter 508mm or 610mm |

Coil Weight 4-8MT |

Quality Commercial and structural quality |

Paint Polyester paint for topside, epoxy for reverse |

Standard JIS G 3312, ASTM A755M, EN 10169 |

Base Steel Grade SGCC,SGCD,DX51D+Z,DX52D+Z;S200GD,S220GD, S280GD,S350GD,CS,FS,SS |

Technical Data Of Prepainted Aluzinc Steel

Yield Strength | (Mpa) 280-320 |

Tensile Strength | (Mpa) 340-390 |

Elongation | 20%-30% |

Reverse Impact | 9J |

T-bending | ≥2T |

Pencil Hardness | ≥2H |

Duration Of Salt Spray Test | 500 H |

Bending At 180 Degree | No crack, purling and fraction |

Application Of Prepainted Aluzinc Steel

Outdoor:

roof, roof structure, surface sheet of balcony,

frame of window, door, door of garage, roller shutter door, booth, Persian blinds, cabana, etc.

In door:

door, isolater, frame of door, light steel structure of house, home electronic appliances, etc.

Packaging & Delivery Of Prepainted Aluzinc Steel

Anti-damp paper inside full wrapped with plastic film, iron sheet outside on wooden pallet in 20 feet container with 25mt.

- Q: im buying a new guitar,, it has a built in tuner and its semi acoustic (can be plugged into an amplifier) ,, im trying to choose which strings are better ,, steel or nylon..?

- i have steel and i like the way it sounds but i like nylon better

- Q: How are steel coils secured during transportation?

- Steel coils are typically secured during transportation using steel strapping, banding, or wire rope. These materials are tightly wrapped around the coils and fastened to prevent any movement or shifting during transit. Additionally, wooden or steel blocking may be used to further secure the coils and prevent them from rolling.

- Q: How are steel coils used in the production of oil and gas equipment?

- Steel coils are used in the production of oil and gas equipment primarily for their strength, durability, and corrosion resistance. These coils are utilized to manufacture various components such as pipes, valves, fittings, and storage tanks that are required in the exploration, drilling, and transportation of oil and gas.

- Q: What are the different types of steel coil packaging?

- There are several different types of steel coil packaging methods used in various industries. Some of the commonly used types include: 1. Wooden Crates: Steel coils are often packed in wooden crates for transportation and storage. These crates provide excellent protection against damage and ensure that the coils remain secure during transit. 2. Steel Frame Bundles: In this packaging method, steel coils are tightly strapped together using steel bands or wires. This creates a sturdy bundle that can be easily lifted and moved using cranes or forklifts. Steel frame bundles are commonly used in industries where the coils are required to be stacked vertically. 3. Steel Strapping: Steel coils can also be packaged using steel strapping. Straps are tightly wrapped around the coils to secure them in place. This method provides good protection against movement and damage during transportation. 4. VCI (Volatile Corrosion Inhibitor) Packaging: VCI packaging is ideal for protecting steel coils from corrosion during storage and shipment. It involves wrapping the coils in special VCI film or paper that releases corrosion-inhibiting molecules. This helps to prevent rust and corrosion, ensuring the coils remain in good condition. 5. Cardboard Packaging: Steel coils can be packaged in cardboard boxes or cartons. This method is commonly used for smaller coils or when additional protection is required. The coils are placed inside the box, which is then sealed to provide a protective barrier against damage and contamination. 6. Stretch Wrapping: Stretch wrapping involves wrapping a plastic film tightly around the steel coils, creating a secure and protective layer. This method is commonly used when the coils need to be protected from dust, moisture, or other external elements. Overall, the choice of steel coil packaging method depends on factors such as coil size, weight, transportation requirements, and the level of protection needed. Each method offers its own advantages and is selected based on the specific needs of the industry and the coils being packaged.

- Q: What are the different methods of annealing steel coils?

- The different methods of annealing steel coils include full annealing, process annealing, spheroidize annealing, and stress relief annealing.

- Q: How do steel coil manufacturers meet customer specifications?

- Customer specifications are met by steel coil manufacturers through a comprehensive and systematic approach that involves various stages and processes. The following are some key steps taken: 1. Thoroughly understanding customer requirements: The process begins with manufacturers gaining a complete understanding of their customers' specific requirements. This includes determining the desired dimensions, tolerances, mechanical properties, surface finish, and any other specific characteristics needed. 2. Selecting the appropriate materials: Based on the customer's requirements, manufacturers carefully select the suitable type and grade of steel to meet the specifications. Factors considered include strength, corrosion resistance, formability, and cost-effectiveness. 3. Planning production: Manufacturers meticulously plan their production processes to ensure that customer specifications are met. This involves determining the appropriate manufacturing techniques, equipment, and resources required. 4. Processing the coils: Steel coils undergo various stages such as hot rolling, cold rolling, annealing, pickling, and coating, depending on the customer's specifications. Each step is meticulously controlled to achieve the desired properties and dimensions. 5. Implementing strict quality control: Throughout the manufacturing process, strict quality control measures are enforced to ensure that the coils meet the customer's specifications. This includes regular inspections, testing, and compliance with industry standards. 6. Offering customization and flexibility: Steel coil manufacturers frequently provide customization options to meet specific customer needs. They have the capability to adjust the thickness, width, and length of the coils to match the desired specifications. 7. Promoting effective communication and collaboration: Effective communication and collaboration between the manufacturer and the customer are crucial in meeting specifications. Manufacturers work closely with their customers to address any concerns or modifications required during the manufacturing process. 8. Providing detailed documentation and certification: Once the steel coils are manufactured, manufacturers supply comprehensive documentation and certifications to ensure traceability and compliance with customer specifications. This includes test reports, material certificates, and any other necessary documentation. By adhering to these steps, steel coil manufacturers can consistently meet customer specifications, guaranteeing that the final product aligns with the desired requirements and quality standards.

- Q: I have a bottle like this* Can u make hot chocolate in it. Can i heat it.I wanna take hot Chocolate to school

- Hot drinks only do well in an insulated thermos. Thermos's were designed for hot drinks. This stainless steel water bottle is not a thermos. You could put hot chocolate or coffee in the water bottle, but you'll burn your hand if you touch it. And, it will cool down very quickly.

- Q: my homework is a breif description on steel pipe. for plumbing/gas.please help me i dont have a clue where to start, something about the thread and where its used.Thanks,

- you can search for some web which sells steel pipe and other relative products to know more details.

- Q: Where can I find a great deal online for Danesco Stainless Steel Egg Poacher

- Danesco okorder /

- Q: What are the weight ranges of steel coils?

- The weight ranges of steel coils can vary widely depending on the specific type and dimensions of the coil. However, typical weight ranges for steel coils can range from a few hundred kilograms to several tons.

1. Manufacturer Overview

| Location | Jiangsu, China |

| Year Established | 2003 |

| Annual Output Value | US$1 Million - US$2.5 Million |

| Main Markets | Southern Asia; America; South America; Eastern Europe |

| Company Certifications | ISO 9000 ISO 14000 OHSAS 18000 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 1% - 10% |

| No.of Employees in Trade Department | 100 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | Above 200,000 square meters |

| No. of Production Lines | 14 |

| Contract Manufacturing | Design Service Offered |

| Product Price Range | Average |

Send your message to us

Prepainted Aluzinc Steel Coil-ASTM A755M

- Loading Port:

- China Main Port

- Payment Terms:

- T/T or L/C

- Min Order Qty:

- 50mt m.t.

- Supply Capability:

- 100,000 mt m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords