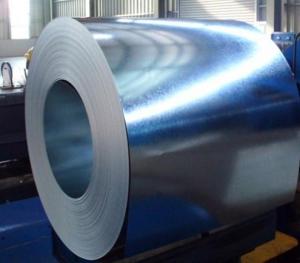

High Quality Hot Dipped Galvanized Steel Coil

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

Hot dipped galvanized steel coil1.Technique: hot dipped galvanized

2.Grade:SGCC,SGCD, DX51D+Z

Hot dipped galvanized steel coil

Thickness | 0.13mm-1.4mm | ||||||

Width | 800mm-1250mm | ||||||

Type | Plate and coil | ||||||

Standard | JIS G3302 GB/T2518 ASTM A653M | ||||||

Material | SGCC, DX51D+Z | ||||||

Coil ID | 508mm/610mm | ||||||

Zinc | 60g/m2 -275g/m2 | ||||||

Technique | Hot dipped galvanized | ||||||

Coil weight | As customer's requirement | ||||||

Application | Construction, shipbuilding, furniture industry, electrical equipment industry, vehicle manufacturing | ||||||

Usage | 1. Construction: roof, roof component, balcony, window, newsstand, warehouse, heating installation, household appliances, refrigeratory, switch box, aircondition, microwave oven, copying-press, electric fan, dust collector 2. Furniture industry: lampshade, chest, desk. Bookrack, medical device 3. Transport industry: car surface, container, expressway fence 4. Others: dustbin | ||||||

MOQ | 20 ton | ||||||

Terms of payment | TT and LC | ||||||

Delivery time | Within 10-15 days after receipt deposit or L/C | ||||||

- Q: What are the different methods of shearing steel coils?

- There are several different methods of shearing steel coils, each offering its own unique advantages and disadvantages. Some of the most common methods include: 1. Guillotine Shearing: This method involves using a guillotine-like machine with a blade that moves vertically to cut through the steel coil. Guillotine shearing offers high efficiency and accuracy, making it suitable for large-scale industrial production. However, it may cause deformation or burrs on the cut edges. 2. Rotary Shearing: In rotary shearing, a set of rotating blades is used to cut through the steel coil. This method allows for continuous cutting, making it ideal for high-speed production lines. It provides a clean and precise cut, but it requires regular maintenance and sharpening of the blades. 3. Slitting: Slitting involves passing the steel coil through a set of circular blades that make multiple parallel cuts. This method is commonly used to produce narrower strips from wider coils. It offers high precision and can produce multiple strips simultaneously. However, slitting may cause edge burrs or camber on the strips. 4. Laser Cutting: Laser cutting uses a high-powered laser beam to melt or vaporize the steel coil along a pre-determined path. This method offers exceptional precision and can cut complex shapes or patterns. It is commonly used for specialized applications where accuracy is crucial, although it can be relatively expensive. 5. Waterjet Cutting: Waterjet cutting utilizes a high-pressure stream of water mixed with abrasive particles to cut through the steel coil. This method is versatile and can handle various materials and thicknesses. It is especially useful for cutting heat-sensitive materials or for applications requiring minimal distortion. 6. Plasma Cutting: Plasma cutting involves ionizing a gas to create a plasma arc that melts and blows away the steel coil. This method is fast and efficient, suitable for cutting thick steel coils. However, it may produce a wider heat-affected zone compared to other methods. 7. Electrical Discharge Machining (EDM): EDM uses electrical discharges to erode the steel coil and create the desired shape. This method is commonly used for intricate or delicate cutting tasks that require high precision. It is particularly effective for hard materials. Each method of shearing steel coils has its own set of advantages and limitations, and the choice depends on factors such as the required precision, speed, material thickness, and the desired end-product.

- Q: What are the common defects found in steel coils?

- Some common defects found in steel coils include surface defects such as scratches, pits, or dents, as well as edge defects like burrs or cracks. Other defects can include coil set or crossbow, which refers to the shape of the coil being out of alignment or having a curved shape. Additionally, defects such as oil or rust stains, laminations, or variations in thickness can also be found in steel coils.

- Q: How are steel coils used in the production of agricultural trailers?

- Steel coils are used in the production of agricultural trailers to provide strength and durability. The coils are shaped into various components of the trailer's structure, such as the frame and chassis. This ensures that the trailer can withstand heavy loads and rough terrain, making it suitable for transporting agricultural equipment and produce.

- Q: How are steel coils used in the manufacturing of HVAC ductwork?

- Steel coils are used in the manufacturing of HVAC ductwork as they provide the necessary strength and durability required for the ductwork. These coils are typically processed through a roll-forming machine, which shapes them into the required ductwork profile. The steel coils are then cut to the desired length, welded or joined together, and finally, coated to prevent corrosion and improve the overall performance of the ductwork.

- Q: This question gets beat to death from what ive seen online but im going to ask it since im searching for a few new knives. The question is as the titles states what is the best steel for a general purpose knife? I plan on buying several different types of knives, Folders, fixed blades, ect. I will carry them around with me all the time for basically anything i can think of to use it for. The reason i ask this question here is because looking online everyone has a differnt veiw. Some say stainless is too soft while others say carbon will chip and is more brittle. Even looking at just a single type of steel, carbon fort instance everyone has a different opinion as to whats best leaving me kind of lost for what i should get. Maybe the better word would be What is a good general purpose steel?. Any advice is much appreciated!!!!

- There is no right one answer, because the term all purpose knife covers a very broad spectrum. The same knife that would be good for wood carving will not be the same for food prep, and will not be the same for general utility purposes. I'll just give you my humble opinion. For fixed blade, hard use blades. Where you will be doing bush tasks like chopping, carving etc... 1095 carbon is generally the standard. Now, 1095 is a great steel, it isn't the BEST steel. There are other steels that can outperform it. But for the price and availability its hard to beat. For folders, I prefer a decent stainless, like aus 8. It holds a good edge, and will hold up to any tasks you need a folding knife to do. Contrary to what you will read on the internet, stainless steel is not all crap. Its just that cheap stainless is just that, cheap. Stainless steel is only as good as its tempering process, some companies such as boker do amazing things with the steel and make for an impressive blade. Just stay away from crap stainless. So to sum up. 1095 for fixed blades. aus 8 for folders. These are both common steels used by different companies. If you get caught up on finding the perfect steel, you may overlook more important aspects of the knife itself. Unless your fixed blade is mostly going to be a food processing, and skinning knife, then I would suggest a QUALITY stainless as well. Remember that all high carbon blades need to be kept oiled or they will start to rust very fast. Btw, I suggest anyone looking into knives to check out mora fixed blades. Incredibly cheap, sharp and durable. They are the rockstars of bushcraft.

- Q: How are steel coils used in the production of industrial boilers?

- Steel coils are used in the production of industrial boilers to form the main body and components of the boiler, such as the shell, tubes, and headers. The coils are shaped and welded together to create a strong and durable structure that can withstand high pressure and temperature conditions. Additionally, the use of steel coils ensures the boiler's efficiency and longevity, as steel is known for its excellent heat transfer properties and resistance to corrosion.

- Q: What is the role of steel coils in the construction industry?

- Steel coils play a crucial role in the construction industry as they are used to manufacture various structural components and building materials. These coils are often transformed into beams, columns, rods, and other structural elements that provide strength and stability to buildings and infrastructure. Additionally, steel coils are also used to produce roofing, siding, and other cladding materials, making them an essential component in construction projects.

- Q: Hello. right now i have been playing electric and acoustic guitar for 6 years. I currently became very interested in learning the pedal steel guitar. I will be teaching myself so is it really hard to learn? Are there a lot of songs online that could give me tabs? Basically im asking if it is worthwhile to spend a lot of money. I dont want it if there are only 3 songs im gona learn. im up for the challenge im just curious how hard it was to learn. thanks for your help.

- The okorder /... Beware of eBay deals unless you know what you're buying. To start, you should get a 10-string single neck with 3 pedals and 4 levers. Some of the student models don't have as many levers and aren't capable of all the changes you need. Stay away from the ShoBud Maverick...you'll outgrow it in a couple of months. Often it makes more sense to buy a used professional model...you'll eventually need one, and they hold their value better than a student model. You'll also need a volume pedal, bar, thumb and finger picks. For now, your guitar amp will be ok. Playing the guitar: There are several tunings and lots of different combinations of levers, but the basic guitar is a 10 string E9 tuning. It's almost an open E but with a few extra notes. The pedals and levers raise and lower the pitch of selected strings. Chord changes are made by moving the bar and pressing pedals and levers. The volume pedal helps you swell and sustain notes. Steel has it's own unique tablature which reflects all these changes. If you have any other questions, feel free to email me or just join the PSG forum and ask there.

- Q: What are the common coil slitting equipment used in the industry?

- The common coil slitting equipment used in the industry include slitter rewinders, rotary shear slitters, and loop slitting machines. These machines are designed to efficiently cut and rewind large coils of material into smaller, narrower coils for various industrial applications.

- Q: What is the thickness range of steel coils?

- The thickness range of steel coils varies depending on the specific application and industry. However, generally speaking, steel coils can have a thickness range from as thin as 0.005 inches (0.13 mm) to as thick as 0.5 inches (12.7 mm) or more.

Send your message to us

High Quality Hot Dipped Galvanized Steel Coil

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords