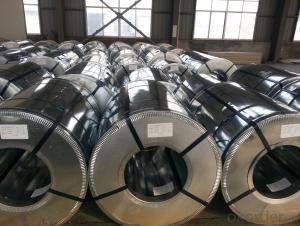

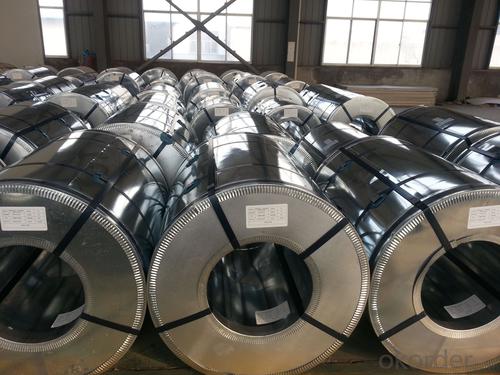

HOT DIP GALVANIZED STEEL IN COIL

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

HOT DIP GALVANIZED STEEL IN COIL

thickness:0.13-2.0mm

width:600-1500mm

material:SGCC,DX51D,Q195

coil weight:3-8 ton

Application:construction field ,ships building industry ,Petroleum and chemical industries ,war and electricity industries ,food processing and medical industry,boiler heat exchanger, machinery and hardware fields

Appliances Industry Outer clad sheets for washing machine, refrigerator, television, air conditioner and ventilation system, explosion-proof strip, solar water heater and appliance parts

Package:covered with waterproof-paper,strapped by strips. Standard seaworthy export package:4 eye bands and 4 circumferential bands in steel, galvanized metal fluted rings on inner and outer edges, galvanized metal & waterproof paper wall protection disk, galvanized metal & waterproof paper around circumference and bore protection.

SPANGLE: normal spangle, large spangle, small(min) spangle, zero spangle

Auto Industry Muffler, heat shields of exhaust pipe and catalytic converter, auto parts & accessories under the frame, signboard in highway

Industrial Instruments Electric control cabinet, industrial refrigeration equipment, automatic vending machine

Architecture Roofs and outside walls of civilian and industrial buildings, garage doors, fencings and window blinds

- Q: How are steel coils used in the production of metal furniture?

- Steel coils are used in the production of metal furniture as they serve as the primary raw material for manufacturing various components such as frames, legs, and supports. These coils are unwound and processed through cutting, bending, and shaping techniques to create the desired shapes and sizes. Additionally, steel coils provide the necessary strength and durability to ensure the longevity and stability of the final furniture products.

- Q: What are the challenges in coil leveling for coated steel?

- Coil leveling for coated steel presents several challenges due to the additional layer of coating. Firstly, the coating can be sensitive to pressure and friction, making it prone to damage during the leveling process. Maintaining the integrity of the coating while achieving the desired flatness of the steel is a delicate balance. Additionally, the thickness of the coating can vary across the coil, leading to uneven leveling results. The choice of leveling equipment and parameters must be carefully determined to minimize coating damage and ensure consistent flatness throughout the coil. Moreover, the presence of coating can impact the accuracy of leveling measurements, as it may interfere with the sensors or affect the readings. These challenges require careful attention and expertise to successfully level coated steel coils while preserving the quality of the coating.

- Q: I live in Dubai. I want to make a damascus steel sword and have no idea where to get the steel or what sort of steel I should get.First to adress the access of my steel...I need to get some low carbon and high carbon steel for the Damascus....what sort of steel is recommended for this? Also where would I be able to get my hands on it (Internet options e.g websites or locations)THANKS

- hI Jordan damascus steel is not actually a steel it is a composite material like the damascus rifle barrels the Afghan's use it is made from wire wrapped around an inner mandrel the beaten on an anvil till all the wire becomes one so it is several types of iron and steel beaten together and forged to produce it so it is not something you can actually buy as a material the tribesmen that produce these swords have these secret methods of doing this so there is the first problem. it is not like cast steel which is what most swords are made of it is far more complex in it's construction. so you may need to do a lot of research to find out how. what is a similar idea is the SAMURAI sword that is made up of combining different steels together and forged into a very sharp and capable killing blade.

- Q: i would like to know of any companies who buy shredded scrap steel

- We are one of the biggest steel mills in Asia. Under our group, we have steel mills in Thailand and Bangladesh. On the monthly basis, we purchase steel scrap HMS1/2 80:20 and the shredded ISRI210/211, ISRI211 by bulk and 20' container to Thailand and Bangladesh. Due to the limitation of our existing shredded steel scrap supplier, we need to get more supply of the shredded. Please contact us or offer us of ISRI 210/211 or ISRI211 CFR Chittagong, Bangladesh with 500mt - 2000mt per shipment by 20' container. If any questions, please feel free to contact us.

- Q: Will a 1 inch thick A36 steel target withstand a 7.62x54r round?

- it depends on the type of steel. If it's soft steel it may stop the round, but leave a craterthat can causeirregular ricochets. If it's hardened steel (AR500 for example), the bullet will just 'splash' and fragment into little bits. It's better to shoot thin steel so the round goes through than shoot thick soft steel thatforms a crater. No matter what type you're shooting, put it no closer than 100 yards for a full power jacketed round. Try to hang the plateso it is angledslightly towards the ground so anymajor ricochets are directed into the ground and not up or back towards you.

- Q: What are the safety standards for steel coil manufacturing?

- To ensure the well-being and protection of workers, as well as the quality and reliability of the products produced, the safety standards for steel coil manufacturing have been designed. These standards encompass various aspects of the manufacturing process and include both general safety guidelines and industry-specific requirements. One of the primary safety standards for steel coil manufacturing involves implementing proper safeguards for machinery and equipment. This entails ensuring that all machinery and equipment used in the manufacturing process are adequately maintained, regularly inspected, and equipped with safety features such as emergency stop buttons and safety guards. Workers must also receive sufficient training on the safe operation of these machines and be aware of potential hazards. Another crucial safety standard is the utilization of personal protective equipment (PPE). Workers engaged in steel coil manufacturing must be provided with appropriate PPE, including safety goggles, gloves, ear protection, and protective clothing, in order to safeguard them against potential hazards such as flying sparks, noise, and chemical exposure. Additionally, safety standards for steel coil manufacturing emphasize the proper handling and storage of materials. This includes guidelines on how to safely lift and transport heavy steel coils, as well as regulations for stacking and storing them to prevent accidents and injuries. Fire safety is also of utmost importance in the safety standards for steel coil manufacturing. Measures should be implemented to prevent and control fires, such as regular inspections of electrical systems, proper storage and handling of flammable materials, and the availability of fire extinguishers and emergency evacuation plans. Furthermore, safety standards necessitate regular safety training and awareness programs for all employees involved in steel coil manufacturing. This ensures that workers are well-informed about potential hazards, safety procedures, and emergency protocols. Regular safety audits and inspections are also conducted to evaluate compliance with these standards and identify areas for improvement. Overall, the safety standards for steel coil manufacturing strive to establish a safe working environment, minimize the risk of accidents and injuries, and ensure the production of high-quality steel coils. Compliance with these standards is crucial for preserving the well-being of workers, protecting the environment, and upholding the reputation of the manufacturing industry.

- Q: How are steel coils measured?

- Steel coils are typically measured in terms of their width, thickness, and weight. The width is determined by measuring the distance across the coil's widest point, while the thickness is measured by gauging the thickness of the steel sheet. The weight of the coil is measured by weighing it using scales or load cells.

- Q: How are steel coils used in the production of steel framing systems?

- Steel coils are used in the production of steel framing systems as they are unrolled and fed into a machine that shapes and cuts the steel into the desired lengths and profiles. These coils provide a continuous supply of high-quality steel, allowing for efficient and precise manufacturing of steel framing components, which are then assembled to create sturdy and durable steel structures.

- Q: I just bought a dpms ar15 and it says if I shoot steel cases (laquer coated) or foreign ammo it voids the warranty. But before I knew this I bought 200 rounds of Russian steel cased anmo. Think I should just shoot there two hundred and not buy anymore? Some people say all they shoot is steel cased ammo and have no problemAny advice is appreciated

- I am not aware of any catastrophic failures being attributed to Russian Steel cased ammo use. I would recommend checking out the several AR15 message boards and see what everyone who uses it has to say and if anyone has had serious problems. I have personally used Wolf steel case in all of my ARs with no serious issues. I have also fired it in several full auto rifles. What I noticed is that it is dirtier ammo than Winchester or Federal ammunition and I will get an occasional failure to eject. Right now, American production brass cased .223 is $.50-$1.00 or more per round when you can find it.. The Russian Wolf can be found for $.40 or less. Most people shoot whatever they can find and afford and do not worry about the warranty.

- Q: I've been looking into battle-ready katanas a lot lately. And I've come across some debates between the best forges and steels to be used for them. The functional katanas I use now are Musashi brand katanas, using 1045 carbon steel. They each cost roughly $200-$250. The straight carbon steels are mentioned in the debates, but they aren't very sophisticated in their design. Now the higher end of this middle class of katana ($250-$1000) uses higher carbon. spring, damascus, and other various steels and combinations. I've heard a lot about the strength of damascus steel and it's cutting power. But I look for more than that. I've also been looking at (and for) durability, flexibility, and how well it stands up to contact. So I guess what I'm asking is for the opinion of people who have used these steels, and an answer on what the community thinks is the best steel for a mid range ($250-$1000) battle-ready katana. Looking forward to some good answers.

- This Site Might Help You. RE: Best battle-ready katana steel? I've been looking into battle-ready katanas a lot lately. And I've come across some debates between the best forges and steels to be used for them. The functional katanas I use now are Musashi brand katanas, using 1045 carbon steel. They each cost roughly $200-$250. The straight carbon...

Send your message to us

HOT DIP GALVANIZED STEEL IN COIL

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords