High Quality Aluminum Standard Profiles Die Cast Aluminum Enclosure

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Die Cast Aluminum Enclosure Description:

Die Cast Aluminum Enclosures are from 150 ton to 2500 ton which provide the wide range of cast part sizes from 0.4” square to over 2’ square. Our world class tooling technology offers solid tools and the plenty experiences of casting parameters control that make our casting parts are accurate, durable and exquisite to compare with the other workmanship. Our competitive offshore price and short first article lead time delivers the fast success of your project.

2.Main Features of the Die Cast Aluminum Enclosure:

·can be easily installed or moved.

·Free from corrosion and carry superior insulation.

·passed waterproof and dustproof carried out under rigid quality standard

·The use is also convenient for the installation of Terminal Substitution Rail, Button Box, Small Terminal,Signal , Relay and Sensor

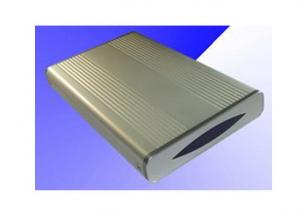

3. Die Cast Aluminum Enclosure Images

4. Die Cast Aluminum Enclosure Specification

Product Class: | die cast aluminum enclosure | ||

Material: | Aluminum & Aluminum alloy A360, A380, A356, ADC12,ADC10, | ||

weight | 0.02-15 kg ( Tolerance :+/- 0.5mm) | ||

Manufacture Process | 1) Process: die cast aluminum enclosure/Metal alloy die casted parts /gravity casting products 2)Secondary Machining: CNC turning, milling, drilling, grinding, assembly to Packing 3) Surface Finish: Chrome plating, sandblasting, painting, anodizing, powder coating, electrophoresis | ||

Surface Treatment | 1)Sand blasting 2)Zinc/chrome plating 3)Powder coating 4)Anodizing 5)Oil injection 6)Brush .etc | ||

Production usage

| 1)Auto parts casting 2)Motorcycle parts 3)Chair parts 4)Locomotive parts 5)Machinery parts 6)Tool parts 7)Radiator 8)Die cast aluminum enclosure .etc | ||

Service | OEM/ODM service are welcomed | ||

Competitive advantage | 1) Small quantity order acceptable 2)Very tight tolerance. 3)Advanced equipment, excellent R&D teams. 4)Strict quality control system. 5)Professional technics and rich experience. 6)Packaging details as client required. | ||

Certification | ISO9001/TS16949,ISO14001,7S |

5.FAQ

1.What is your mOQ?

1000pieces

2. How about your delivery time?

About one month

3.How to order?

First,Customers could send us your sample or drawing,such as 2D and 3D drawing(IGS or STP format) Second,Our engineers will check the drawing carefully and then provide you a better price. Third, If you accept, then order confirmed.

- Q: Are aluminum profiles suitable for structural applications?

- Yes, aluminum profiles are suitable for structural applications. Aluminum is a lightweight and highly versatile material that offers excellent strength-to-weight ratio, corrosion resistance, and durability. These properties make it ideal for various structural applications such as architectural frameworks, bridges, aerospace structures, automotive frames, and industrial equipment. Additionally, aluminum profiles can be easily fabricated, welded, and joined, allowing for efficient construction and customization. With proper design and engineering considerations, aluminum profiles can provide the necessary strength and stability required for structural applications.

- Q: How are aluminum profiles cut and shaped?

- Aluminum profiles can be cut and shaped using a variety of methods depending on the desired outcome. One common method is cutting the profiles using a saw. This can be done manually with a hand saw or by using a power saw such as a miter saw or a circular saw. These saws are equipped with specially designed blades that are capable of cutting through aluminum. Another method is using a CNC (Computer Numerical Control) machine. CNC machines are highly precise and can be programmed to cut and shape aluminum profiles with great accuracy. This method is often used for more complex and intricate designs. In addition to cutting, aluminum profiles can also be shaped using various techniques. One common method is bending. Aluminum profiles can be bent to a desired angle using specialized bending machines. These machines use force to gradually shape the aluminum without causing any damage or deformation. Another shaping technique is extrusion. Extrusion involves forcing the aluminum through a die to create a specific shape. This method is commonly used in the manufacturing of aluminum profiles with consistent cross-sectional shapes such as tubes or beams. Overall, the cutting and shaping of aluminum profiles require specialized tools and machinery to achieve the desired results. The specific method used will depend on the complexity of the design and the desired outcome.

- Q: Is it possible to utilize aluminum profiles in regions with low temperatures?

- <p>Yes, aluminum profiles can be used in cold climates. Aluminum is a durable material with excellent resistance to corrosion and weathering, including low temperatures. It maintains its strength and does not rust or degrade in cold conditions. However, it's important to consider thermal expansion and contraction, as aluminum expands and contracts more than some other materials. Proper design and installation practices can mitigate these effects, making aluminum profiles suitable for use even in extreme cold environments.</p>

- Q: What is the difference between the type 4040c and 4040d of aluminum profile?

- Sometimes there are differences in wall thickness, and sometimes there are differences between strengthening and non strengthening.

- Q: This question asks for the various types of adhesives that can be used for bonding aluminum profiles to building structures.

- <p>There are several types of adhesives used to attach aluminum profiles to building structures, including epoxy adhesives, which offer high strength and resistance to chemicals and temperature changes; polyurethane adhesives, known for their flexibility and durability; acrylic adhesives, which provide good adhesion on a variety of surfaces and are resistant to UV light; and silicone adhesives, which are excellent for sealing and bonding in environments with fluctuating temperatures. Each adhesive type has specific properties that make it suitable for different applications and environmental conditions in construction.</p>

- Q: Can aluminum profiles be used for exhibition stands?

- Indeed, exhibition stands can utilize aluminum profiles. Lightweight and adaptable, aluminum profiles prove to be a prime selection for exhibition stands. Their effortless assembly and disassembly facilitate convenient transportation and storage. Furthermore, aluminum profiles can be tailored to suit the particular design and layout prerequisites of an exhibition stand. They can be employed in fabricating frames, partitions, and display panels, resulting in a robust and polished structure. Incorporating aluminum profiles into exhibition stands also permits the flexibility to incorporate accessories such as lighting fixtures, shelving, and signage, thereby augmenting the overall visual allure and functionality of the stand.

- Q: Are aluminum profiles suitable for use in transportation vehicle bodies?

- Transportation vehicle bodies can benefit from the use of aluminum profiles. Aluminum is a material that is both lightweight and durable, making it suitable for this purpose. By utilizing aluminum profiles, vehicles can achieve a reduced weight, resulting in improved fuel efficiency and lower emissions. Furthermore, the excellent strength-to-weight ratio of aluminum profiles enables them to withstand the stresses and loads experienced by transportation vehicles. The corrosion resistance of aluminum is also advantageous, especially for vehicles exposed to harsh environmental conditions. Additionally, the flexibility of aluminum profiles allows for easy formation and shaping into complex designs, providing versatility in vehicle body construction. Overall, the adoption of aluminum profiles in transportation vehicle bodies presents numerous advantages, contributing to its widespread popularity in the industry.

- Q: This question asks about the various materials used to coat aluminum profiles for improving their appearance.

- <p>There are several types of coating materials used on aluminum profiles for aesthetic purposes, including: 1. Powder coating, which offers a durable and colorful finish. 2. Anodizing, a process that enhances the surface hardness and provides a decorative effect. 3. Electrophoretic coating, known for its smooth and even finish. 4. PVDF (Polyvinylidene Fluoride) coating, which is weather-resistant and offers a wide color palette. 5. Thermal spraying, which can provide a decorative or protective layer. 6. Sol-gel coating, a newer technology that offers excellent adhesion and corrosion resistance. These coatings not only enhance the visual appeal but also protect the aluminum from environmental factors and wear.</p>

- Q: What are the different types of surface coatings for aluminum profiles?

- There are several different types of surface coatings that can be applied to aluminum profiles, each with their own unique characteristics and benefits. 1. Anodizing: Anodizing is a popular coating method that involves creating a protective oxide layer on the surface of the aluminum. This layer not only enhances the appearance of the profile but also improves its resistance to corrosion, wear, and scratches. Anodized aluminum profiles can be further enhanced through color dyeing or other finishing techniques. 2. Powder coating: Powder coating is a dry finishing process that involves applying a powdered coating material to the aluminum profile. The powder is electrostatically charged and then applied to the profile, after which it is heated to form a durable and attractive coating. Powder coating offers excellent protection against scratches, UV rays, and chemical damage, making it a popular choice for outdoor applications. 3. Liquid paint coating: Liquid paint coatings can also be applied to aluminum profiles. This method involves spraying or dipping the profile into a liquid paint solution, which is then cured to form a tough and durable finish. Liquid paint coatings offer a wide range of color options and can be customized to achieve specific aesthetic requirements. 4. PVDF coating: Polyvinylidene fluoride (PVDF) is a high-performance coating material that provides exceptional resistance to weathering, fading, and corrosion. PVDF coatings are typically applied through a liquid paint process and can be used to achieve long-lasting and vibrant finishes on aluminum profiles, especially in architectural applications. 5. E-coating: Electrocoating, also known as electrophoretic deposition (EPD), involves immersing the aluminum profile in a bath of paint or coating solution and applying an electric current to deposit the paint uniformly onto the surface. E-coating provides excellent coverage and adhesion, making it suitable for complex-shaped profiles. It also offers good corrosion resistance and can be used as a primer before applying other coatings. Overall, the choice of surface coating for aluminum profiles depends on the specific requirements of the application, including desired appearance, durability, corrosion resistance, and environmental factors. Each type of coating has its own advantages and limitations, so it is important to carefully consider these factors before making a selection.

- Q: This question asks about the various methods for connecting aluminum profiles using fasteners.

- <p>There are several ways to join aluminum profiles together using fasteners: 1. Bolts and Nuts: Commonly used for strong and removable connections. 2. Rivets: Provide a permanent connection, suitable for high-stress applications. 3. Screws: Offer a secure and adjustable connection, often used in furniture and construction. 4. Pins: Used for alignment and positioning, often in lighter applications. 5. Adhesives: Can be used for a more aesthetically pleasing joint, though not as strong as mechanical fasteners. 6. Welding: Although not a fastener method, it is a common way to join aluminum profiles for a permanent and strong bond. Each method has its advantages and is chosen based on the specific requirements of the application, such as strength, permanence, and ease of assembly.</p>

Send your message to us

High Quality Aluminum Standard Profiles Die Cast Aluminum Enclosure

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords