Aluminum Profiles South Africa - Aluminium Cast Slab Not Alloyed in Coil Form

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Structure of Aluminium Cast Slab not Alloyed in Coil Form Description:

Coated aluminum coil/sheet are of a wide range of colors, which gives wonderful appearance no matter in residential and commercial constructions of great exhibition centers.

The coated aluminum coil/sheet have been widely used in the fields of construction and decoration( garage doors, ceiling etc.), electronic appliances, lighting decoration, air-condition air pipes, sandwich panels and drainages etc.

Main Features of the Aluminium Cast Slab not Alloyed in Coil Form:

1) High flexibility

2) Impact resistance

3) Excellent weather-proof durability

4) Anti-ultraviolet

5) High erosion resist

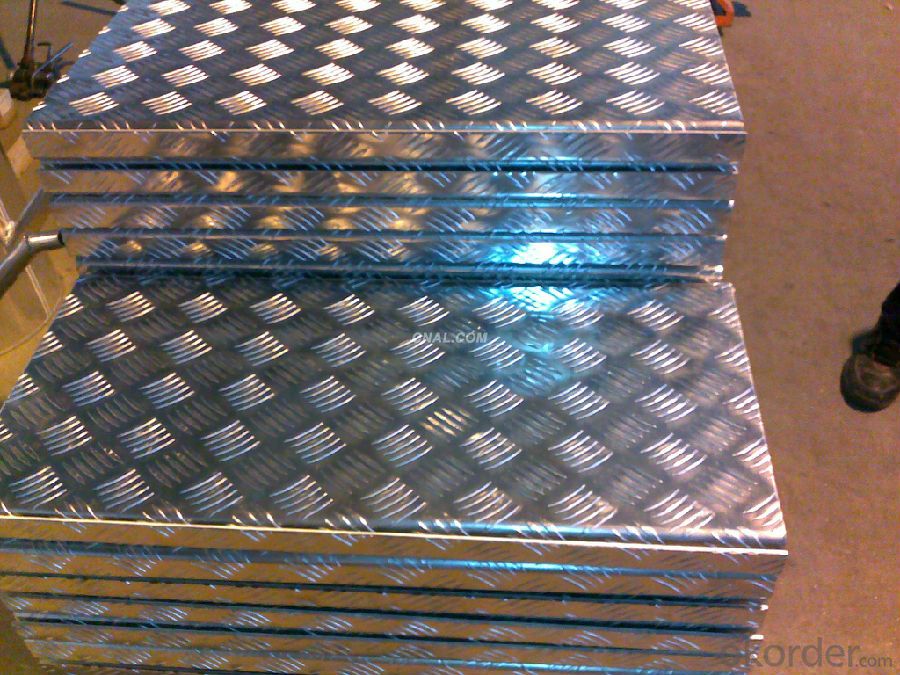

Images of the Aluminium Cast Slab not Alloyed in Coil Form:

Aluminium Cast Slab not Alloyed in Coil Form Specification:

Alloy | A1100,A3003,A1050,A8011 etc |

Temper | H16,H18,H24 |

Thickness | From 0.024mm to 1.2mm |

Width | Standard width:1240mm |

Special width:1300mm,1520mm,1570mm,1595mm | |

Diameter | Standard dia:1200mm |

Interior dia:150mm,405mm,505mm | |

Weight | 2.5 T/coil,3.0 T/coil |

Coating | PE, PVDF, AC |

Surface | Embossed, mill finish, coated |

Color | AS to code RAL |

Gloss | 10-90%(EN ISO-2813:1994) |

Coating Thickness | PE: more than 18 micron |

PVDF: more than 25 micron | |

Coating Hardness (pencil resistance) | More than 2h |

Coating adhesion | 5J(EN ISO-2409:1994) |

Impact Resistance | No peeling or cracking(50 kg/cm,ASTMD-2794:1993) |

Flexibility (T-bend) | 2T |

MEK resistance | More than 100 |

FAQ Aluminium Cast Slab not Alloyed in Coil Form:

a.What is monthly capacity

---CNBM is one stated own company and our monthly capacity is about 2000tons.

b. Now which countries do you export your goods?

---Now we export to South East Asia,Africa, North America,South America ect.

- Q: What are the different surface treatments for aluminum profiles?

- Some of the different surface treatments for aluminum profiles include anodizing, powder coating, painting, and polishing.

- Q: How do aluminum profiles perform in terms of heat resistance?

- Aluminum profiles generally exhibit good heat resistance. Aluminum has a high thermal conductivity, allowing it to efficiently dissipate heat. Additionally, aluminum profiles can withstand high temperatures without deforming or losing structural integrity. However, extreme temperatures, especially above 600°C, can cause aluminum to gradually lose strength. Therefore, it is important to consider the specific application and temperature requirements when evaluating the heat resistance of aluminum profiles.

- Q: Can aluminum profiles be an alternative to steel or other materials?

- Yes, aluminum profiles can be a viable alternative to steel or other materials in many applications. Aluminum profiles offer several advantages over steel, such as being lightweight, corrosion-resistant, and highly durable. One of the key benefits of aluminum profiles is their low weight. Aluminum is approximately one-third the weight of steel, making it an ideal choice when weight reduction is a priority. This lightweight nature makes aluminum profiles easier to handle, transport, and install, reducing overall costs and labor requirements. Additionally, aluminum profiles possess excellent corrosion resistance properties, especially when compared to steel. Aluminum naturally forms a protective oxide layer when exposed to air, which prevents further oxidation and corrosion. This makes aluminum profiles suitable for applications in industries such as construction, automotive, aerospace, and marine, where exposure to moisture, saltwater, or harsh weather conditions is common. Another advantage of aluminum profiles is their high strength-to-weight ratio. Aluminum alloys can be engineered to provide exceptional strength while still being lightweight. This makes them an excellent choice for structural applications where both strength and weight reduction are crucial. Furthermore, aluminum profiles are highly durable and can withstand extreme temperatures. Aluminum has a melting point of 660 degrees Celsius, significantly higher than most other non-ferrous metals. This makes it suitable for applications where exposure to high temperatures or thermal stress is expected. Aluminum profiles can also be easily fabricated, allowing for complex shapes and designs. They can be extruded, machined, welded, or formed into various configurations to meet specific requirements. This flexibility in manufacturing processes makes aluminum profiles a versatile material choice. However, it is important to note that aluminum profiles may not be suitable for all applications. Steel still offers superior strength and rigidity, making it more appropriate for heavy-duty applications or areas where high impact resistance is required. Additionally, aluminum profiles can be more expensive compared to steel, depending on the specific alloy and manufacturing processes involved. In conclusion, aluminum profiles can serve as a viable alternative to steel or other materials in many applications. Their lightweight nature, corrosion resistance, high strength-to-weight ratio, durability, and ease of fabrication make them an attractive choice for various industries. However, the specific requirements of each application should be carefully considered before deciding on the most suitable material.

- Q: Are there any limitations or drawbacks to using aluminum profiles?

- Yes, there are some limitations and drawbacks to using aluminum profiles. Firstly, aluminum is a relatively soft metal compared to steel, which means it may not be as strong or durable in certain applications. Additionally, aluminum profiles can be more expensive than other materials such as wood or plastic. They also have lower resistance to high temperatures, which can lead to warping or deformation. Finally, aluminum profiles may require additional surface treatments or coatings to protect against corrosion in certain environments.

- Q: Are there any specific safety precautions when working with aluminum profiles?

- Yes, there are specific safety precautions when working with aluminum profiles. These include wearing appropriate personal protective equipment such as gloves, safety glasses, and hearing protection. It is also important to ensure proper ventilation in the workspace to prevent inhalation of aluminum dust or fumes. Additionally, precautions should be taken to avoid sharp edges and use proper lifting techniques to prevent injury.

- Q: What does aluminum 6063 T5 mean?

- 6063 is a kind of 6 alloy, T5 is quenched, air-cooled

- Q: Are aluminum profiles suitable for industrial workstations?

- Yes, aluminum profiles are suitable for industrial workstations. Aluminum is a lightweight and durable material that provides excellent strength and stability, making it ideal for use in industrial settings. It has high corrosion resistance, which helps to prolong the lifespan of the workstations. Additionally, aluminum profiles can be easily customized and assembled, allowing for flexibility and adaptability in designing the workstations to meet specific industrial needs. The material is also environmentally friendly, as it is 100% recyclable, which aligns with the growing emphasis on sustainability in the industrial sector. Overall, aluminum profiles offer numerous advantages for industrial workstations, making them a suitable choice for various applications in industrial settings.

- Q: Can aluminum profiles be customized according to specific requirements?

- Indeed, specific requirements can be accommodated through the customization of aluminum profiles. This adaptable material can be effortlessly manipulated, trimmed, and formed to adhere to diverse design specifications. The dimensions, shape, thickness, and surface finish of aluminum profiles can all be personalized. Furthermore, drilling, bending, welding, and powder coating are additional processes that can be employed to further tailor aluminum profiles, achieving desired functionality and aesthetic allure. Such customizability renders aluminum profiles fitting for an extensive array of applications across industries, including construction, automotive, aerospace, and electronics.

- Q: This question asks if aluminum profiles can be used in cold weather conditions and if they maintain their properties in such environments.

- <p>Yes, aluminum profiles are suitable for use in cold climates. Aluminum is a durable material with excellent resistance to corrosion and weathering, which includes maintaining its integrity in low temperatures. It does not rust or degrade significantly in cold conditions, making it a reliable choice for construction and other applications in cold climates. However, it's important to consider the specific alloy and any protective coatings or treatments that may be necessary to ensure optimal performance in extreme cold.</p>

- Q: What are the different surface engraving or etching techniques for aluminum profiles?

- There are several surface engraving or etching techniques available for aluminum profiles, each offering unique benefits and results. Some of the commonly used techniques include: 1. Chemical Etching: This process involves the use of chemicals to selectively remove the top layer of the aluminum profile. It allows for precise and intricate designs to be etched onto the surface, making it suitable for decorative purposes. 2. Laser Engraving: Laser engraving utilizes a high-powered laser beam to vaporize the aluminum surface, creating a permanent etching. This technique offers excellent precision, allowing for detailed designs and logos to be engraved onto the profile. 3. Mechanical Engraving: Mechanical engraving involves the use of rotary cutters or diamond-tipped tools to physically engrave the surface of the aluminum profile. This technique is commonly used for industrial applications, such as marking product codes or serial numbers. 4. Electrochemical Etching: This technique uses an electric current and an electrolyte solution to etch the aluminum surface. It is commonly employed for creating durable and legible markings, such as product labels or identification codes. 5. Sandblasting: Sandblasting involves directing a stream of abrasive particles at high speed onto the aluminum surface. This process removes the top layer of the material, leaving a textured or frosted appearance. Sandblasting is often used for decorative purposes or to create a matte finish. 6. Acid Etching: Acid etching utilizes an acid solution to selectively remove the top layer of the aluminum surface. This technique is commonly used for creating a matte or satin finish, as well as for creating patterns or textures on the profile. These engraving and etching techniques offer a wide range of options for aluminum profiles, allowing for customization, branding, or functional purposes. The choice of technique depends on factors such as the desired design, level of detail, durability requirements, and the intended application of the aluminum profile.

Send your message to us

Aluminum Profiles South Africa - Aluminium Cast Slab Not Alloyed in Coil Form

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords