Bosch Profiles Aluminum A380 High Quality Die Cast

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Structure of A380 Aluminum Die Cast Description:

These are used when the casting alloy cannot be used in hot-chamber machines; these include aluminium, zinc alloys with a large composition of aluminium, magnesium and copper. The process for these machines start with melting the metal in a separate furnace. Then a precise amount of molten metal is transported to the cold-chamber machine where it is fed into an unheated shot chamber (or injection cylinder). This shot is then driven into the die by a hydraulic or mechanical piston. The biggest disadvantage of this system is the slower cycle time due to the need to transfer the molten metal from the furnace to the cold-chamber machine.

2.Main Features of the A380 Aluminum Die Cast:

Drawing: provide by customer, or we design as the sample.

Mold: Design and produce by ourself.

Product Material Option: A360, A380, ADC12, ADC3, AlsSi7Mg, AlSi12, AlSi9Cu3, etc.

SURFACE TREATMENT

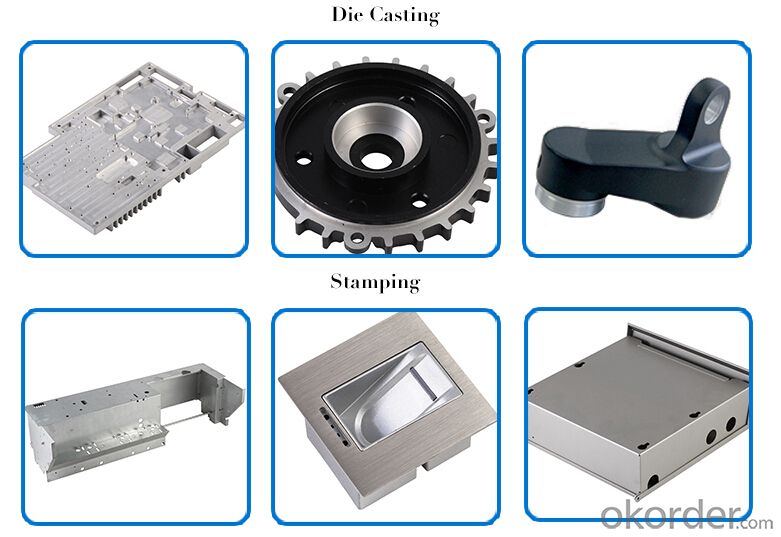

3. A380 Aluminum Die Cast Images

4. A380 Aluminum Die Cast Specification

Process | Material Grade | Weight range | Application |

Investment casting, sand casting, ESR casting Die casting Metal casting

| Iron: Grey iron, Ductile iron Steel: Carbon steel, Alloy steel, Stainless steel Nonferrous metal: Bronze, Brass, Al, Zinc, Ti, etc. | From 0.01Kg to 100 ton | Auto motive, agricultural machines, vessels, toolings, mining , oi l& gas machinery, locomotive industry, aerospace, hardware, contruction, engineering machinery, electrical equipment etc. |

5. RFQ

1).What kind of the materials can be provided?

Product Materials: mainly is Aluminum alloy. But we also can provide other material products for you: like zinc alloy, iron, stainless steel, plastic. Because we are very familiar with them, and better service for you

Mould Materials: H13,3Cr2W8V,4Cr5MoVlsi,SKD61,8407#

According to customers’ requirement

2).What your payment terms?

TT or LC

3).What is the privacy policy of your company?

We respect for all the customers, and make all the customers information confidential. We limit the scope of the information provided to third parties, and we allow its use only the customer permits.

- Q: This question asks for a list of various types of aluminum profiles that are commonly used in the construction industry.

- <p>Aluminum profiles used in construction come in various types, each with specific applications. Common types include: 1. Extruded Profiles: These are the most common, formed by forcing aluminum through a die to create different shapes and sizes. 2. Structural Profiles: Used for structural integrity, such as beams and columns. 3. Decorative Profiles: For aesthetic purposes, like trims and moldings. 4. Industrial Profiles: Designed for specific industrial applications, like conveyor systems. 5. Window and Door Profiles: Specifically designed for window and door frames. 6. Heat Sink Profiles: Used for dissipating heat in electronic devices. 7. Railing Profiles: For constructing railings and balustrades. 8. Solar Profiles: Used in solar panel mounting systems. Each type has unique properties and is chosen based on the specific requirements of the construction project.</p>

- Q: Explain how aluminum profiles contribute to the energy efficiency of a building.

- <p>Aluminum profiles significantly enhance the energy efficiency of a building through several mechanisms. They are lightweight yet strong, reducing the overall weight of the structure and the energy required for construction. Their excellent thermal conductivity allows for efficient heat transfer, which can be managed with proper insulation to reduce heat loss. Aluminum profiles also facilitate better window and door sealing, minimizing drafts and heat leakage. Additionally, their high reflectivity can help in reflecting solar heat, reducing the need for cooling. Lastly, aluminum profiles can be used in the construction of solar panels and other renewable energy systems, further contributing to a building's energy efficiency.</p>

- Q: Can aluminum profiles be used for DIY projects or home improvement?

- Aluminum profiles have multiple applications in DIY projects and home improvement. Their versatility allows for easy cutting, shaping, and joining, enabling the creation of diverse structures and components. Despite being lightweight, they possess strength and durability, making them suitable for various projects. Whether you desire a personalized shelving unit, a garden fence, a solar panel frame, or even a one-of-a-kind furniture piece, aluminum profiles prove to be an excellent choice. Moreover, they possess corrosion resistance and require minimal upkeep, making them perfect for outdoor undertakings as well. With the appropriate tools and a touch of creativity, aluminum profiles can be transformed into functional and visually appealing additions to your home.

- Q: How do aluminum profiles contribute to energy-saving initiatives?

- Aluminum profiles play a significant role in promoting energy-saving initiatives for several reasons. Firstly, aluminum is a lightweight material, which means that less energy is required during transportation and installation compared to other heavy construction materials. This reduces the overall carbon footprint associated with the construction process. Additionally, aluminum profiles have excellent thermal conductivity properties. This enables them to efficiently transfer heat, which is crucial for energy-saving initiatives. By using aluminum profiles in windows, doors, and facades, buildings can benefit from improved insulation and reduced thermal bridging. This helps to maintain a comfortable indoor temperature while minimizing the need for excessive heating or cooling, thus reducing energy consumption. Moreover, aluminum profiles can be effectively combined with energy-efficient glazing systems. These systems include double or triple glazing, low-E coatings, and gas-filled cavities, which further enhance the thermal performance of windows and facades. By using aluminum profiles in conjunction with energy-efficient glazing, buildings can significantly reduce heat loss or gain, resulting in reduced energy usage for heating and cooling. Furthermore, aluminum is a highly durable and long-lasting material. Its corrosion resistance properties make it suitable for use in various weather conditions, reducing the need for frequent replacements. This durability ensures that the energy-saving benefits provided by aluminum profiles are maintained over an extended period, reducing the environmental impact associated with frequent material replacements. Lastly, aluminum is a recyclable material with a high recycling rate. The energy required to recycle aluminum is significantly lower compared to the energy needed for primary production. By promoting the use of aluminum profiles, we encourage the recycling and reuse of this material, thereby reducing the demand for new aluminum production and conserving energy resources. In conclusion, aluminum profiles contribute to energy-saving initiatives by reducing transportation and installation energy consumption, improving thermal insulation, facilitating energy-efficient glazing systems, providing durability, and promoting recycling. By incorporating aluminum profiles in construction projects, we can significantly contribute to energy conservation and sustainability efforts.

- Q: Are aluminum profiles suitable for use in sustainable or eco-friendly construction projects?

- <p>Yes, aluminum profiles can be used for green building projects. They are valued for their recyclability, which contributes to sustainability. Aluminum is lightweight, strong, and requires less energy to produce and transport compared to other materials like steel. Additionally, aluminum's durability can lead to a longer lifespan, reducing the need for frequent replacements and thus minimizing waste. Moreover, aluminum can be used in energy-efficient designs, such as in window frames that provide better insulation, further enhancing the green credentials of a building.</p>

- Q: What are the advantages of using aluminum profiles in the defense industry?

- There are several advantages of using aluminum profiles in the defense industry. Firstly, aluminum profiles offer high strength-to-weight ratio, making them ideal for applications requiring lightweight yet durable components. This allows for the development of lighter military vehicles, aircraft, and other defense equipment, which ultimately enhances mobility and fuel efficiency. Secondly, aluminum profiles possess excellent corrosion resistance properties, ensuring the longevity and reliability of defense systems even in harsh environments. This is particularly crucial for military equipment that operates in various weather conditions and may be exposed to saltwater or corrosive agents. Additionally, aluminum profiles can be easily machined and fabricated into complex shapes, allowing for customization and innovative designs, which can optimize performance and functionality. These profiles also offer good electrical conductivity, making them suitable for applications requiring electrical grounding or electromagnetic shielding. Lastly, aluminum is a highly recyclable material, aligning with sustainability goals. This not only reduces waste but also supports the defense industry's efforts towards environmental stewardship. Overall, the advantages of using aluminum profiles in the defense industry include lightweight strength, corrosion resistance, versatility in design, electrical conductivity, and sustainability.

- Q: How do aluminum profiles contribute to sustainable packaging solutions?

- Aluminum profiles play a crucial role in promoting sustainable packaging solutions due to their numerous eco-friendly properties. Firstly, aluminum is a highly recyclable material, and its profiles can be easily recycled without losing their inherent qualities. This allows for a closed-loop recycling system, reducing the need for new raw materials and minimizing waste. Additionally, aluminum profiles offer exceptional strength and durability, ensuring that packaging made from these profiles can withstand rigorous handling and transportation. This durability reduces the likelihood of damage or breakage, resulting in less product waste and minimizing the need for additional packaging materials. Moreover, aluminum profiles provide excellent barrier properties, protecting the contents of the packaging from external factors such as moisture, oxygen, light, and temperature variations. This helps to extend the shelf life of the products, reducing food waste and ensuring that goods remain fresh and safe for consumption. Furthermore, aluminum profiles are lightweight, which contributes to energy savings during transportation. The lightweight nature of aluminum packaging allows for reduced fuel consumption and lower carbon emissions, making it an environmentally friendly choice. Lastly, aluminum profiles are resistant to corrosion, ensuring that the packaging remains intact and functional for an extended period. This longevity reduces the need for frequent replacement, saving resources and minimizing the overall environmental impact. In summary, aluminum profiles contribute to sustainable packaging solutions by being recyclable, durable, providing excellent barrier properties, lightweight, and corrosion-resistant. These properties help to minimize waste, reduce energy consumption, extend product shelf life, and lower carbon emissions, making aluminum profiles an ideal choice for eco-conscious packaging solutions.

- Q: What are the different machining techniques for aluminum profiles?

- Some of the different machining techniques for aluminum profiles include milling, drilling, turning, and sawing. These techniques are used to shape, cut, and create various features on aluminum profiles, such as holes, slots, chamfers, and intricate designs. Additionally, other techniques like grinding, polishing, and sanding may be employed to achieve the desired surface finish on the aluminum profiles.

- Q: What are the noise insulation properties of aluminum profiles?

- Aluminum profiles have relatively poor noise insulation properties compared to other materials commonly used for soundproofing, such as wood or PVC. Aluminum is a lightweight and thin material, which allows sound waves to easily pass through it. It does not provide a significant barrier to block or absorb sound, resulting in minimal noise reduction. However, certain aluminum profiles can be designed with additional features to enhance their noise insulation capabilities, such as incorporating insulating materials or using thicker profiles. These modifications can improve the soundproofing performance to some extent, but it still may not be as effective as other materials specifically designed for noise insulation.

- Q: What do the 6063 and T5 represent in the aluminum profile 6063-T5?

- 5: the main alloying element is magnesium6: mainly add alloy elements for silicon and magnesium7: the main alloying elements are zinc and magnesium8: a new alloy that does not belong to the above alloy series2.2, second digits: an alloy that indicates the addition of alloying elements or impurities in the original alloy0: table alloy1: table original alloy by the first amendment2: table original alloy after second modifications2.3,

Send your message to us

Bosch Profiles Aluminum A380 High Quality Die Cast

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords