Steam Control Valve High quality best price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 111 PCS

- Supply Capability:

- 1000 PCS/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery

| Packaging Detail: | carton or wooden case |

| Delivery Detail: | 30 days |

Specifications

Since 1958.

1).Standard: API6D, CE, IBR, JIS..

2).Certificate: ISO 9001, TS..

3).PN10~PN250..

4).WCB, CF3, CF3M, CF8, CF8M..

| Part Name | Material | |||||

| Body, Bonnet | WCB(ZG230-450), WCC(ZG270-500), WC6(ZG15CrMo), CF8(304), CF8M(316), CF3(304L), CF3M(316L) | |||||

| Plug, Seat | 304(0Cr18Ni9), 316(0Cr17Ni12Mo2), 316L(00Cr17Ni14Mo2) 17-4PH | |||||

| Packing | PTFE, R.TFE, Grafoil | |||||

| Sealing Ring | XB350, PTFE | |||||

| Stem | 304 316 316L 17-4PH | |||||

| Nominal Diameter DN | 20 | 25 | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 | |

| Rate Flow Coefficient | Linear | 6.9 | 11 | 17.6 | 27.5 | 44 | 69 | 110 | 176 | 275 | 440 | 690 |

| Equal-Percent | 6.3 | 10 | 16 | 25 | 40 | 63 | 100 | 160 | 250 | 400 | 630 | |

| Rate Travel | 16 | 25 | 40 | 60 | ||||||||

| Electrical Actuator Type | 361LSA-08 381LSA-08 PSL201 | 361LSA-20 381LSA-20 PSL202 | 361LSB-30 381LSB-30 PSL204 | 361LSC-65 381LSC-65 PSL312 | ||||||||

| Nominal Diameter DN | 250 | 300 | 350 | |||||||||

| Rate Flow Coefficient | Linear | 1000 | 1650 | 2160 | ||||||||

| Equal-Percent | 900 | 1500 | 2000 | |||||||||

| Rate Travel | 100 | 100 | 100 | |||||||||

| Electrical Actuator Type | 361LSC-99/381LSC-99/PSL314 | |||||||||||

| Nominal Pressure(Mpa) | Mpa | 1.6, 2.5, 4.0, 6.4(6.3)/2.0, 5.0, 11.0, 15.0 | ||||||||||

| Bar | 16, 25, 40, 64(63)/20, 50, 110, 150 | |||||||||||

| Lb | ANSI: Class150, Class300, Class600, Class900 | |||||||||||

| Inherent Flow Characteristic | Equal-Percentage, linear | |||||||||||

| Inherent Adjust Rate | 50 | |||||||||||

| Eletricity Supply | 220V 50HZ Please notify if choose the anther electricity supply | |||||||||||

| Input Signal | 4~20mA | |||||||||||

| Feedback Signal | 4~20mA | |||||||||||

| Allowable Leakage | ANSI B16.104 Class IV | |||||||||||

| Temperature | Normal Temp | -20~200, -40~250, -60~250 | ||||||||||

| Radiator | -40~350, -60~450 | |||||||||||

| High Temp | 450~650 High Temperature Material | |||||||||||

| Low Temp | D0:-60~-100, D1:-100~-200, D2:-200~-250 | |||||||||||

| Adjusting & Stopping | -40~150 (PTFE-PTFE), -60~200 (PTFE-Reinforced PTFE) | |||||||||||

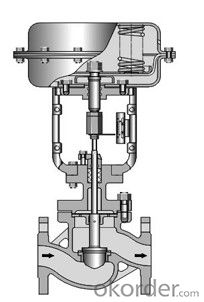

| SINGLE SEAT CONTROL VALVE | |

| The structure of the single seat control valve series is the simplest among all the kinds of control valves, with the accurate flow characteristic, lightest weight and most widely usage. The advantages of this series valves has least leakage, and less pressure reduction losses than the cage and double seat control valves. If the allowable pressure is available, the single seat control valves shall be the first option compare to the cage or double seat kinds. | |

| FEATURES: 1.Compare to other kinds valves, the single seat valve usually has the bigger unbalanced force (Ft) when it closed, so the matched actuator must have the enough output force, if the working condition is beyond the allowable pressure, do not choose the single seat valves as possible. |

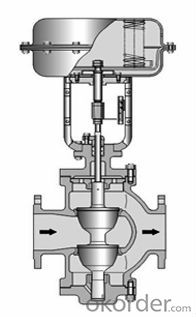

| DOUBLE SEAT CONTROL VALVE | |

| There are two units’ seat, plugs and sealing surface in the normal type double seat control valves, while as for the cage type, it also has two units sealing surface, but it only has one plug. Because of the two flow channel, so the flow capacity (flow efficiency Kv) of the double seat control valves are bigger than the single seat type, but the leakage grade is lower than the single seat type, it is usually grade II, at most grade III. | |

| 1.Forbid to choose the double seat control valves for the conditions of small opening and small flow capacity. 2.If the single seat type or cage type is available for the working condition, do not choose the double seat control valves. 3.As for the control valve with the diameter DN is bigger than 250mm, choose the rotatory valve ( V-shaped ball valve, butterfly valves, eccentric valves) to replace the double seat control valves if possible, otherwise there is a requirement of precise flow characteristic. 4.There is big leakage for the double seat control valve, consider cautiously before opting. |

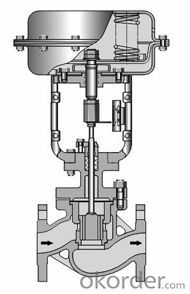

| CAGE TYPE CONTROL VALVE | |

| The structure of the cage type control valve series is the relative simpler among all the kinds of control valves with the accurate flow characteristic. Besides the single seat control valve, the cage type control valve is secondly most used among all the kinds of control valves. It plays an important role in the nine kinds control valves types, in one project, the quantity of the cage type valves some time will exceeds 60% among all the control valves. | |

| 1.Because of the balanced plug, this series valves are able to bear big differential pressure, while the matched output force from the actuator is relatively small. 2.Because of the balanced plug, this series valve can be operated stably without frequent vibration. 3.The windows on the cage are deployed symmetrically, the total flow kinetic energy consumes in the core of the cage, so the other inside partare not easy to be damaged, then the noise is lower, the working life is longer. 4.The windows on the cage can be made to meet different flow characteristic according to the working requirement, so the valves with same diameter are able to meet many different requirement of flow capacity CV. |

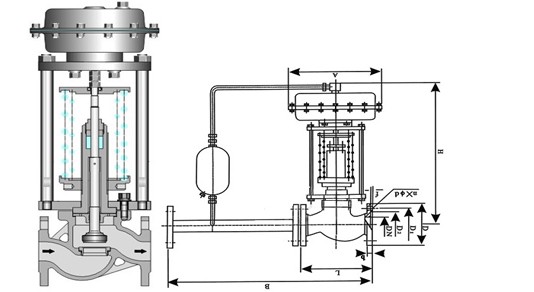

| SELF-OPERATED REGULATOR | |

| The self-operated pressure regulator is a kind which does not need outside power but take advantage of the power from medium to act and adjust by itself. The most notable feature of this series regulator is that it can be used in the working place without the electricity and gas supplying, which saves the power at the same time. In the specific range, the pressure setting can be adjusted at will.So it can be widely used in many fields like petroleum, chemical,electricity, metallurgy, food, textile, machinery and civilian building and so on to reduce/release or stabilize the pressure of the gas, steam and liquid and so on. | |

|

- Q: What valve should be used to test the water valve?

- Switch and multi way valve in the pipeline not only can flow, and flow diversion, flexible control of the medium, but also to turn off any channel to the other two channels. This kind of valve should be installed horizontally in the pipeline. Classification of ball valve: pneumatic ball valve, electric ball valve, manual ball valve.

- Q: What does the 4 point valve mean?

- The caliber is DN15's valve. What valves do you need?

- Q: How to quickly identify the types of valves?

- The "Practical Handbook" valve design on the valve structure, with precision, surface roughness and typical design standard, the valve has hundreds of models, and continue to have a new valve, see a written one, is shorthand

- Q: According to the original valve installed on it, but never demolished, I am afraid to force over, will not be broken? The old valve, that part of the remaining three tubes tight.

- Look, the valve you bought looks like PVC hot melt.. If the old valve and the elbow must be rejected with a hacksaw, hot melt and buy a new elbow and PVC section pipe for hot melt machine welding. From the picture didn't see traces of the thread,

- Q: What are the uses and differences of gate valves, butterfly valves, ball valves and other valves?

- The use of the same difference, you can see the shape

- Q: I'm going to put a solar energy and an electric water heater installed in the same hot water pipe, a valve, a valve open and close the valve B and vice versa the installation of solar and electric water heater, there can be no linkage valve?

- Yes, three ball valves (T and L) are two. Switch more complex point of the valve is basically ball valve, such as central air-conditioning commonly used to the four - way reversing valve.

- Q: What is the purpose of the valve?

- Valve is a pipe accessory. It is a device used to change the direction of the passage and the direction of the medium flow, and to control the flow of the conveying medium.Valves have the following uses:1. Connect or cut off the medium in the pipe. Such as gate valve, globe valve, ball valve, plug valve, diaphragm valve, butterfly valve and so on.2 、 adjust and control the flow and pressure of the medium in the pipeline. Such as throttle, control valve, pressure reducing valve, safety valve, etc..

- Q: How much is the 150LB of the valve?

- Valves can be used to control air, water, steam, a variety of corrosive media, mud, oil, liquid metal and radioactive media and other types of fluid flow.

- Q: How do you calculate the flow of the valve?

- Valve flow calculation value is very vague, pipe pressure, back pressure, medium viscosity, medium temperature, valve structure, and so on, will affect the calculated value.

- Q: What's the material of j41h-16p's valve?

- The j41h-16p valve is a stainless steel globe valve.The working principle of stop valve:The cut-off valve, also called the door, is the most widely used as a valve, it is popular is because the process of opening and closing the sealing surface friction between the small, more durable, highly open small, easy manufacture, convenient maintenance, not only for low pressure, but also suitable for high pressure.The closing principle of the valve is to rely on the valve bar pressure, so that the valve sealing surface and seat sealing surface close together, to prevent the circulation of media.The one-way valve can only medium flow direction when installing. The structure length of the stop valve is larger than that of the gate valve, and the fluid resistance is large, and the reliability of the sealing is not strong during the long-term operation.

Send your message to us

Steam Control Valve High quality best price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 111 PCS

- Supply Capability:

- 1000 PCS/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords