Geotextile Underlayment Fabric with High-Density Fiberglass Geogrid and High Tensile Strength

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

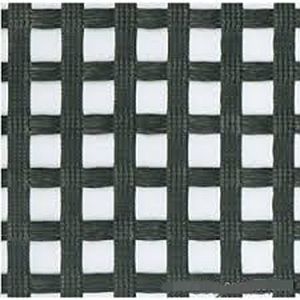

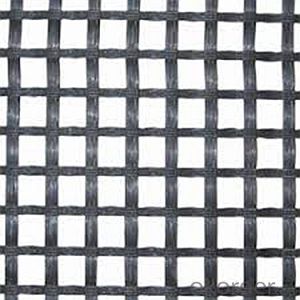

Classify Fiberglass Geogrid Classify Polyester Geogrid

Material Fiberglass Material Polyester

Tensile Strength: 25-25KN; 30-30KN; 50-50KN; 80-80KN; 100-100KN; 120-120KN;

Road Size: 3.95x100m; as customer required;

Fiberglass Geogrid features

1. Light weight, high tensile strength, high modulus, low elongation and good

toughness.

2. Corrosion resistance, no long-term creep, long life span.

3. Good physical and chemical stability and good thermal stability.

4. Resistant to fatigue cracking, high-temperature track and low temperature

shrinkage cracking.

5. Delaying and decreasing crack reflection.

Packaging & Shipping

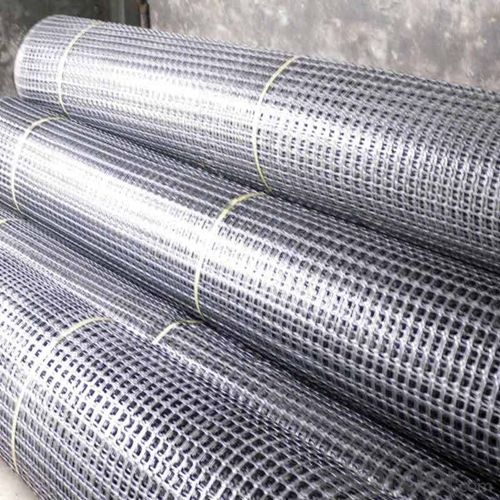

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

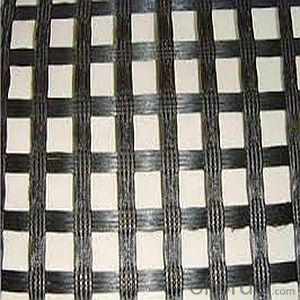

geotextile fabric

permeability,filtration,easy for construction

ISO and CE certificate

Good quality and competitive price

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q: Are geotextiles commonly used in civil engineering projects?

- Yes, geotextiles are commonly used in civil engineering projects. They are versatile materials that provide various benefits such as soil stabilization, erosion control, filtration, and drainage. Geotextiles are used in applications like road construction, retaining walls, landfills, and erosion control measures, making them an essential component in many civil engineering projects.

- Q: How can the geotextile extension of 65 to do the following

- I professional production geotextile geomembrane and other geotechnical materials, wish smooth

- Q: Is there a geotextile for reed cultivation?

- Big slope pond words use better, need depth laying, with geomembrane

- Q: What are the cost considerations for geotextiles?

- The cost considerations for geotextiles depend on factors such as the type and quality of the geotextile, the required strength and durability, the size of the project, and the installation method. Generally, higher-quality geotextiles with better performance characteristics tend to be more expensive. Additionally, the quantity of geotextile required for a project and the labor costs associated with installation can significantly impact the overall cost. Therefore, it is essential to carefully analyze the specific needs of the project and compare prices from different suppliers to make an informed decision.

- Q: Are geotextiles poisonous?

- Geotextile is not toxic, the production of geotextile raw materials are polyester (PET) or polypropylene (PP). Polyester and polypropylene have become daily necessities. Many of the mineral water bottles are also produced by PET and PP raw materials.

- Q: Is the polypropylene composite geotextile and the polyethylene composite geomembrane the same?

- Geotextiles and geomembranes are not the same, but they complement each other to meet the engineering requirements. First introduced under the geotextile: geotextile is the state for civil engineering in the construction of a new type of construction materials, by filament or short fiber through different equipment and process shop into a mesh, and then after acupuncture and other processes to different Fibers are intertwined with each other, tangent to the fabric to make the fabric normal, so that the fabric is soft, plump, thick, stiff, to meet the different thickness to meet the requirements, according to the length of silk is divided into filament non-woven geotextile or short wire Non-woven geotextile, filament tensile strength higher than the short wire. Fibrous soft with a certain tear resistance. The main role is: filter, filter, reinforcement role. Specifications from 100 grams per square meter to 800 grams per square meter. The main material for the polyester fiber, with excellent permeability, filtration, durability deformation adaptability, and has a good flat drainage capacity (see below) Geomembrane to plastic film as anti-seepage substrate, and non-woven composite Made of geotextile impermeable material can be divided into two cloth a film, a cloth a film, its impermeability depends mainly on the plastic film impermeability. The geomembrane is a waterproof barrier material with the polymer of the polymer chemical material as the basic raw material. The proportion of small, strong extension, high adaptability to adapt to deformation, corrosion resistance, low temperature, good frost resistance. (See below)

- Q: Can geotextiles be used in geosynthetic encased columns?

- Yes, geotextiles can be used in geosynthetic encased columns as they provide reinforcement, filtration, and separation functions. They help to improve the stability and performance of these structural elements by enhancing soil confinement and preventing the loss of fine particles.

- Q: What are the different geotextile installation techniques in reinforcement?

- There are several geotextile installation techniques used in reinforcement, including direct placement, wrap-around, and anchor trenching. In direct placement, the geotextile is simply laid directly on the ground and covered with soil or aggregate. Wrap-around technique involves placing the geotextile around the object being reinforced, such as a pipe or retaining wall, and securing it in place. Anchor trenching involves burying the geotextile in a trench and anchoring it with soil or other materials to provide additional strength and stability.

- Q: Can geotextiles be used in the protection of underground tanks?

- Yes, geotextiles can be used in the protection of underground tanks. Geotextiles are commonly used as a protective layer to prevent damage to underground tanks from surrounding soil movement or external pressure. They provide an effective barrier between the tank and the surrounding soil, reducing the risk of punctures, abrasions, and corrosion. Additionally, geotextiles can help with filtration and drainage, ensuring proper functioning and longevity of the underground tank.

- Q: What is the difference between finished and semi-finished products?

- Think of ways to develop customers in the country Well. Foreigners may now also like, in the future may also like to like something else. We have the domestic people's own preferences are unable to control, but also control the other countries ah?

Send your message to us

Geotextile Underlayment Fabric with High-Density Fiberglass Geogrid and High Tensile Strength

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords