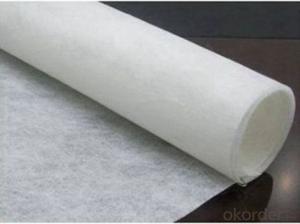

Geotextile Avant Ou Apres Tout Venant PP Woven Geotextile for Long Fibers with High Strength

- Loading Port:

- Qingdao

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Features:

Polyester filament geotextile is made by polyester textile needle consolidation , product specifications from 80-800g/m2 , it is geosynthetic application in geotechnical and civil engineering , they are arranged in three-dimensional structure of the fiber . In addition to having good mechanical properties, but also has a good aspect to the drainage performance and good elongation properties and high resistance to biological , acid , anti-aging chemical stability . Meanwhile , it also has a wide range of pore size , pore distribution tortuous , excellent permeability and filtration performance .

2. Action:

1, Water conservancy project dams and slope of filtration , channel isolation, impervious ;

2, Highways , railways, airport runways based isolation, filtration , drainage, slopes, retaining walls and pavement reinforcement, drainage ;

3, Port engineering soft ground , beach causeway , harbor piers and breakwaters reinforcement, drainage ;

4, Polyester filament geotextile has been widely used in the field of infrastructure construction , and gradually be applied to a wider range of fields.

3. Technical data:

Index | Remark | |||||||||||

100 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 600 | 800 | ||

Deviation of mass per unit area % | -6 | -6 | -6 | -5 | -5 | -5 | -5 | -5 | -4 | -4 | -4 | |

Thickness mm ≥ | 0.8 | 1.2 | 1.6 | 1.9 | 2.2 | 2.5 | 2.8 | 3.1 | 3.4 | 4.2 | 5.5 | |

Width deviation % | -0.5 | |||||||||||

Break strength kN/m | 4.5 | 7.5 | 10.5 | 12.5 | 15 | 17.5 | 20.5 | 22.5 | 25 | 30 | 40 | Vertical and horizontal |

Break elongation % | 40~80 | |||||||||||

CBR bursting strength kN ≥ | 0.8 | 1.4 | 1.8 | 2.2 | 2.6 | 3.0 | 3.5 | 4.0 | 4.7 | 5.5 | 7.0 | |

Equivalent aperture mm | 0.07~0.2 | |||||||||||

Vertical permeability cm/s | K*(10-4~10-3) | K=1.0~9.9 | ||||||||||

Tear strength kN≥ | 0.14 | 0.21 | 0.28 | 0.35 | 0.42 | 0.49 | 0.56 | 0.63 | 0.70 | 0.82 | 1.10 | Vertical and horizontal |

FAQ of our geotextile:

- Q: What can we do for the special customer?

A: Provide custom made service with customer's drawing; We make sure to provide you with the best solutions for your individual case. Whether standard items or non-standard items.

- Q: What can we supply?

A: We provide high levels of communication from start to finish.

- Q: What is our advantage?

A: Top Cemented Carbide has extensive business experience, Fast delivery and high quality.

Erosion problems have been with us since man first learned how to cultivate the land he lived in. Fortunately, many solutions have been produced since that time. One such solution is the use of woven geotextiles. Woven geotextiles are a permanent fabric to assist in the retention of soil in many different situations. Their purpose is to provide a porous foundation for separating particles of varying sizes. Another use is to allow moisture to penetrate the material, but restrict plant life from starting.

Erosion control can sometimes involve using something called a "riprap", which is when non-porous objects are used to slow down the velocity of waterflow. Common objects are large stones or concrete slabs. This reduces the chance of damaging the land. When a riprap is constructed, there are usually different particle sizes of material used. To help keep them separated and in place, woven geotextiles can be placed between the different layers. This will help control the flow of water and reduce the chance of erosion of not only the surrounding soil, but the different parts and layers of the riprap.

Woven geotextiles are used in a great deal in landscaping projects. These serve as permanent barriers against any unwanted vegetation from sprouting up in places where they are not wanted. These barriers are commonly placed three to six inches below the surface. Top soil is placed over the top and the ordimental vegetation is then planted. The woven material allows not only water to flow through it, but also provides a protective barrier to help retain the moisture during very hot and dry conditions.

On construction sites, woven geotextiles are commonly used to cover the soil after it has been disturbed by normal activities. When placed over piles of soil, these coverings make it so the piles can withstand downpours from rain and not be turned into nuisance dust by the wind. These are temporary covers that are used until the soil is ready to be used again or put back to where it came from.

Sometimes the woven geotextiles are used as a filter to assist with separating out the fine particles from the larger materials. Occasionally, the material can become clogged and needs to be replaced and the fine materials are redistributed or disposed of.

- Q: Can geotextiles be used in pond liner systems?

- Yes, geotextiles can be used in pond liner systems. Geotextiles are often employed as a protective layer or underlayment for pond liners to enhance their performance and prevent punctures or damage. They can help with drainage, filtration, and soil stability, making them a valuable component in pond liner systems.

- Q: What are the key factors affecting the hydraulic conductivity of geotextiles?

- The key factors affecting the hydraulic conductivity of geotextiles include the porosity of the fabric, the size and shape of the openings or pores in the fabric, the fabric thickness, and the surface roughness of the fabric. Additionally, the type and quality of the fibers used in the geotextile can also impact its hydraulic conductivity.

- Q: Can geotextiles withstand harsh weather conditions?

- Yes, geotextiles are designed to withstand harsh weather conditions. They are made from durable materials that can resist extreme temperatures, heavy precipitation, and UV radiation. Additionally, geotextiles have excellent drainage properties, ensuring they can handle excessive moisture and prevent erosion even in challenging weather conditions.

- Q: Geotextile how to sampling

- Related methods can refer to GB-1998, can also go to our factory to purchase, to observe. My contact is the name of the registration. Free testing training! All the country's site can be shipped!

- Q: Will the HDPE geomembrane, non-woven geotextile re-examination to detect what project? Is there a basis for testing? Thank you, hurry! The The

- CBR top breaking strength, vertical permeability coefficient ,,

- Q: What are the materials used in geotextile production?

- Geotextiles are typically produced using a variety of materials, including synthetic fibers such as polypropylene, polyester, and polyethylene. These materials are chosen for their durability, strength, and resistance to environmental conditions. Natural fibers like jute and coir can also be used in certain geotextile applications. Additionally, some geotextiles may incorporate additives or coatings to enhance their performance and stability.

- Q: How do geotextiles help in reducing the settlement of structures on soft soils?

- Geotextiles help in reducing the settlement of structures on soft soils by providing a stable and reinforced foundation. They act as a barrier between the soil layers, distributing the load evenly and preventing excessive settlement. Additionally, geotextiles improve the soil's drainage and filtration capabilities, allowing water to permeate and preventing waterlogging, which can further contribute to settlement.

- Q: What are the key factors affecting the tensile strength of geotextiles?

- The key factors affecting the tensile strength of geotextiles include the type and quality of the raw materials used, the manufacturing process employed, the thickness and density of the geotextile, and the presence of any additives or coatings. Additionally, environmental factors such as temperature, moisture, and exposure to UV radiation can also influence the tensile strength of geotextiles.

- Q: How do geotextiles help with reinforcement of geogrid reinforced soil slopes?

- Geotextiles help with the reinforcement of geogrid reinforced soil slopes by providing an additional layer of strength and stability. They act as a separator between the geogrid and the soil, preventing soil erosion and maintaining the integrity of the slope. The geotextiles also distribute the load over a larger area, reducing the stress on the geogrid and enhancing its effectiveness in reinforcing the soil. Overall, geotextiles play a crucial role in enhancing the performance and longevity of geogrid reinforced soil slopes.

- Q: Can geotextiles be used in geosynthetic clay liner caps?

- Yes, geotextiles can be used in geosynthetic clay liner caps. Geotextiles are often used as a protective layer over geosynthetic clay liners to prevent soil intrusion, enhance filtration, and provide additional stability to the liner system.

1. Manufacturer Overview

| Location | Taian City,Shandong Province,China |

| Year Established | 2008 |

| Annual Output Value | Above US$100 Million |

| Main Markets | Africa, Oceania, North America, Western Europe, Eastern Asia |

| Company Certifications | ISO9001;IS014001 Certificate |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

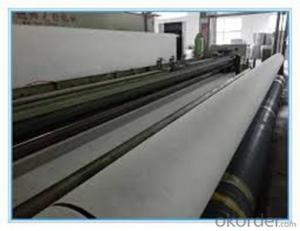

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Qingdao Port;Tianjing Port;Shanghai Port |

| Export Percentage | |

| No.of Employees in Trade Department | 21-30 People |

| Language Spoken: | English; Chinese; |

| b) Factory Information | |

| Factory Size: | 10,000-30,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | Geotechnical Material (Geogrid,Fiberglass/Polyester Geogrid,Geocell,Geonet and Geomat,Plastic Safety Fence) |

| Product Price Range | Average |

Send your message to us

Geotextile Avant Ou Apres Tout Venant PP Woven Geotextile for Long Fibers with High Strength

- Loading Port:

- Qingdao

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords