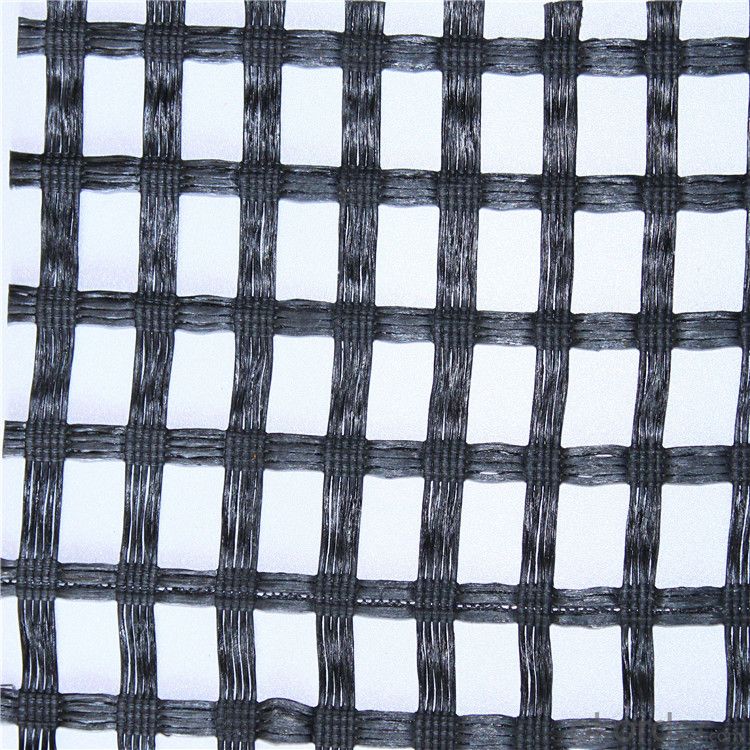

Flexible Fiberglass Geogrids with High Tensile Strength

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

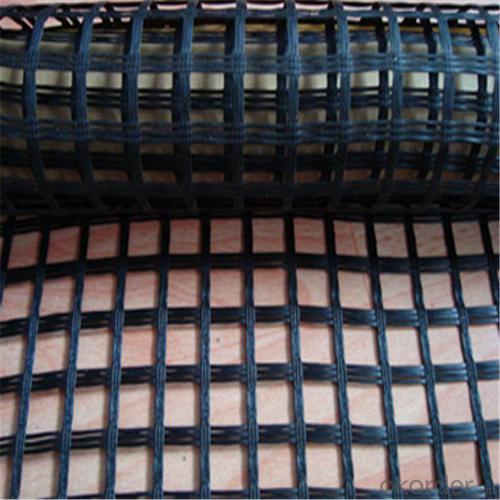

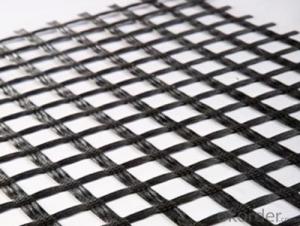

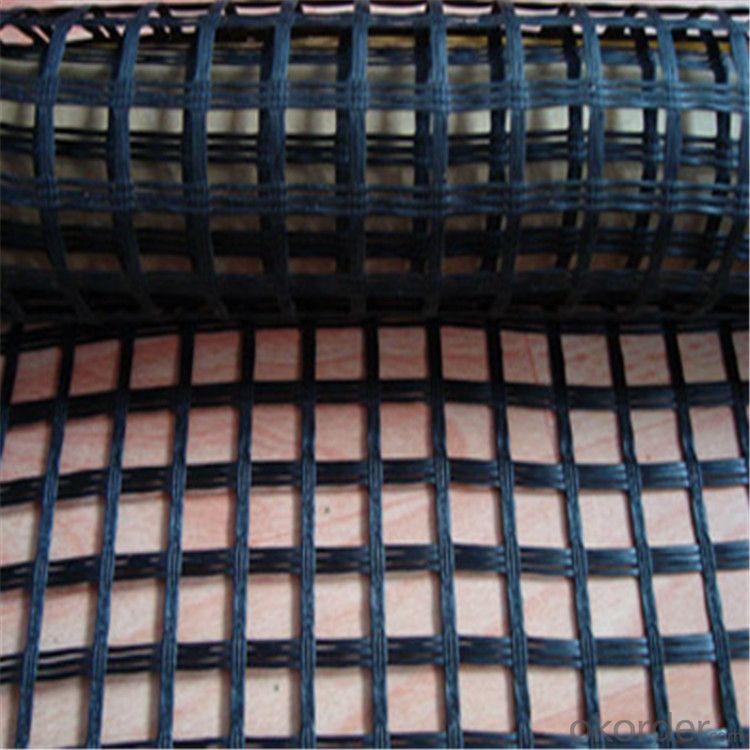

Product Specification---Fiberglass Geogrid

Introduction:

Fiberglass geogrid is a kind of new favorable earthwork base material to strengthen the road surface and roadbed. This product is composed of fiberglass filaments that are coated with an inorganic sizing agent

Features:

1. High tensile strength in warp and across directions

2. Low Elongation

3. High flexibility

4. High and low temperature resistance

Application:

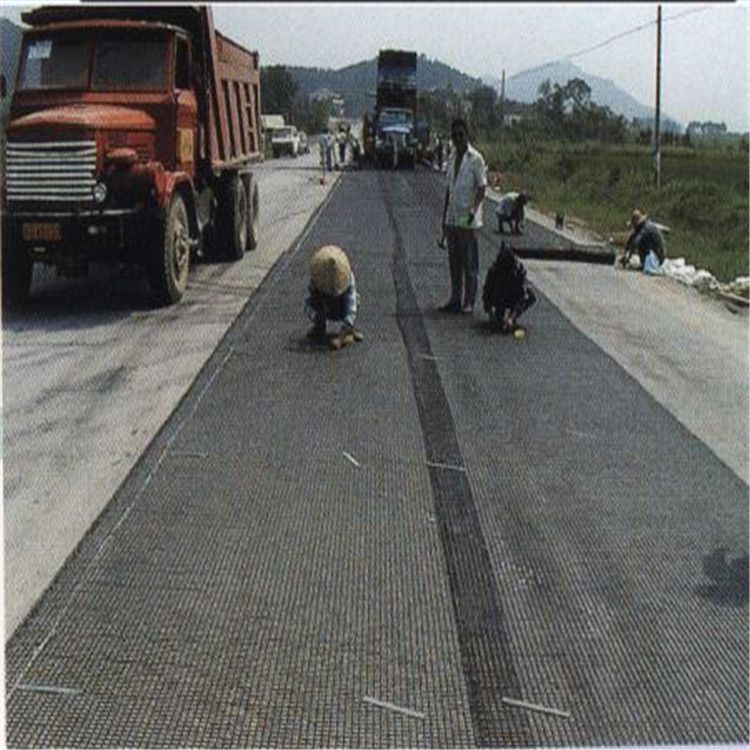

This product is used to strengthen the soft land, such as railway, airport, irrigation work, and dyke, roadbed, and softland loading capacity strengthen.

Function:

This product is made by weaving and covering fiberglass filament. It is featured by high vertical and horizontal tensile

strength, low unit extension, high flexibility, and favorable high and low temperature resistance. The products after

surface covering own the favorable property of alkali resistance and aging resistance.

It is used widely to increase the asphalt road surface, concrete road and roadbed (both soft and hard road surfaces).

Compared with the traditional road surface, it reduces the cost, prolong the service life, and avoid the reflection road

crackle.

This product is also used to strengthen the soft land, such as railway, airport, irrigation work, and dyke, etc, and the

roadbed 。

Properties of Fiberglass Geogrid

Specification | EGA30-30 | EGA50-50 | EGA80-80 | EGA100-100 | EGA120-120 | |

Mesh size(mm) | 25.4×25.4 Or 12.5×12.5 | |||||

Breaking strength ≥(KN/m) | Warp direction | 30 | 50 | 80 | 100 | 120 |

Across warp | 30 | 50 | 80 | 100 | 120 | |

Elongation at break ≤(%) | Warp direction | 3 | ||||

Across warp | 3 | |||||

Elasticity modulus(GPA) | 67 | |||||

Thermal tolerance | -100~280℃ | |||||

Width | 1~6m | |||||

Image of Fiberglass Geogrid

- Q: What are the advantages of using geogrids in soil nailing applications?

- Geogrids offer several advantages in soil nailing applications. Firstly, they enhance the stability and strength of soil by acting as a reinforcement material. This helps to prevent slope failures and soil erosion. Secondly, geogrids improve the overall performance and lifespan of structures by providing a reliable method of soil stabilization. Additionally, they are cost-effective and relatively easy to install, making them a practical choice for soil nailing projects.

- Q: Can geogrids be used in green roof applications?

- Yes, geogrids can be used in green roof applications. Geogrids provide structural reinforcement and stability to the green roof system, allowing for the successful growth and maintenance of plants and vegetation on the roof. They help distribute the weight of the green roof evenly, prevent soil erosion, and enhance drainage, making them a valuable component in green roof construction.

- Q: What is the recommended geogrid junction strength?

- The recommended geogrid junction strength varies depending on the specific application and project requirements. It is important to consult with geotechnical engineers or manufacturers to determine the appropriate geogrid junction strength for each unique situation.

- Q: Are geogrids suitable for use in bridge approaches?

- Yes, geogrids are suitable for use in bridge approaches. Geogrids provide reinforcement and stabilization to the soil, preventing erosion and settling, which are common issues in bridge approaches. Additionally, they enhance the load-bearing capacity of the soil, allowing for the safe passage of vehicles over the bridge.

- Q: Unidirectional tensile plastic geogrid manufacturers which good

- As the polymer in the manufacture of plastic polymer in the process of heating with the extension of the process of re orientation, strengthen the link between the molecular chain force, to achieve the purpose of improving its strength. Its elongation rate is only 10% ~ ~ of the original plate of 15%

- Q: What are the durability characteristics of geogrids?

- Geogrids are highly durable materials that are designed to withstand heavy loads, extreme weather conditions, and long-term stress. They possess excellent tensile strength and do not easily deform or deteriorate under constant pressure. Geogrids are resistant to corrosion, biological degradation, and chemical exposure, making them suitable for various applications in civil engineering and construction projects. Their durability characteristics ensure long-lasting performance and effective reinforcement of soil structures.

- Q: What is the meaning of reinforced subgrade? Is there a geogrid type on the road?

- Reinforced embankment subgrade usually with earthwork material, application is very flexible, such as mesh woven with the willow branches can also do the laying of reinforcement materials in the soil, reinforced net can also, but each has advantages and disadvantages, according to the actual needs of the design.

- Q: Are geogrids resistant to chemical attack?

- Yes, geogrids are generally resistant to chemical attack. They are typically made from high-density polyethylene (HDPE) or other durable materials that can withstand exposure to various chemicals without significant degradation. However, the specific resistance to chemicals may vary depending on the type of geogrid and the specific chemicals involved. It is always advisable to consult the manufacturer's specifications and guidelines to ensure compatibility with specific chemical environments.

- Q: What are the different testing methods for geogrids?

- There are several different testing methods for geogrids, including tensile strength testing, aperture size testing, creep testing, and junction efficiency testing. Tensile strength testing measures the maximum load a geogrid can withstand before breaking, while aperture size testing determines the size of the openings in the geogrid to ensure they meet the required specifications. Creep testing evaluates the geogrid's ability to maintain its strength over time under constant load, and junction efficiency testing assesses the strength of the connections between the geogrid's intersecting strands. These testing methods help ensure the quality and performance of geogrids in various applications.

- Q: What are the differences between geogrids and geonets?

- Geogrids and geonets are both geosynthetic materials used in civil engineering and construction, but they differ in structure and function. Geogrids are typically made of high-strength polymer materials, such as woven or knitted polyester or polypropylene, and have a grid-like structure. They are used to reinforce soil and provide tensile strength to the ground. Geogrids distribute loads over a wider area, reducing soil settlement and improving stability. They are commonly employed in applications like retaining walls, roads, embankments, and slopes. On the other hand, geonets are formed by extruding polymeric materials into a net-like configuration. They have a three-dimensional structure characterized by interconnected voids or channels. Geonets are used for drainage purposes, providing a pathway for liquids to flow through the material while preventing clogging. They are commonly used in applications such as landfill liners, subsurface drainage systems, and erosion control. In summary, the main difference between geogrids and geonets lies in their structure and function. Geogrids provide reinforcement and tensile strength to the soil, while geonets facilitate drainage and prevent clogging.

Send your message to us

Flexible Fiberglass Geogrids with High Tensile Strength

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords