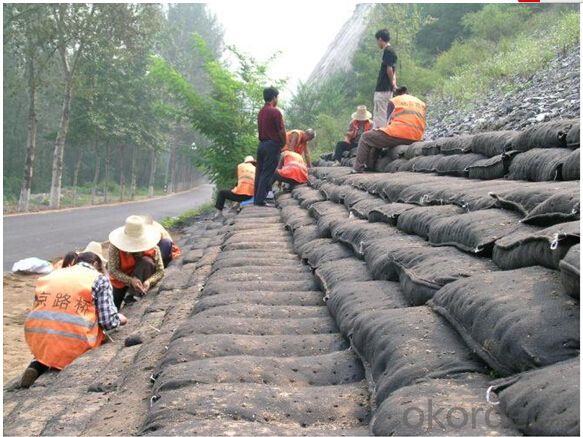

Geo Bag for Flood Controls/ Slope Protecion/Greening Environmental

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 pc

- Supply Capability:

- 500000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Product Introudction of Geo Bag: Geotextile sand bag made of PE or PP, with good corrosion resistance ,excellent chemical resistance,the UV resistance. The products can be applied in construction projects such as water conservancy projects,river bank protection, dams, road and railway project, airport, environmental protection projects, in which play the important role of filtration, drainage, separability, and reinforcement. 2. Technical Sheet of Geo Bag: Item Unit Weight g/m2 100 125 150 200 Tensile Strength KN/m ≥4.5 Elongation at break % ≥40 Material PP or PET CBR Mullen Burst Strength KN ≥0.8 ≥1.1 ≥1.4 ≥1.8 Tearing Strength KN ≥0.14 ≥0.17 ≥0.21 ≥0.28 3. Application of Geo Bag: Ecological restoration 1) On both sides of the river: Natural bank with the environment of human and wildlife coexistence 2). Green mine recovery: Comprehensive utilization of mine gangue, scientific renovation subsidence area, greening of barren hills, purifying water, create the mine ecological restoration, barren hills and green complex in New Era 3). The lake shore, the sea surface landslide, culvert hole, a drainage ditch, soil erosion, irrigation system 4). Artificial wetland: Ecological restoration 5). Roof greening Infrastructure construction 1). Road slope protection: Railway, highway slope protection, suitable for cut slope and fill slope 2). Lake revetment: Applicable to the river, lake, reservoir slope. 3). Special application: Military facilities and emergency flood control, flood control dams bunker, etc. Landscaping and residential garden 1)Vertical greening, landscape art 2)Commercial and residential district 3)Roof garden green

4. FAQ of Geo Bag:

Q1. How is the delivery time?

Delivery: Within 2 weeks upon the receipt of the deposit.

Q2. What's are the MOQ?

The MOQ is different for different products, for our first cooperation we can accept your first trial order volume.

Q3. Are the free samples availale?

Yes, the free samples are available. We will charge the express fee based on the area sent, your express account is the top choice for samples sending

Geosynthetics are the man-made material which is having the basic feature of improving the soil conditions. These are made up from such plastics which will not decompose easily from fungal as well as bacterial action.

They are used to solve the main problems of civil engineering along with being available in a vast range of materials and forms which is used differently by different users.

These products are more durable when they are used on the ground. They are also used in transportation and private development fields like roadways and railways.

How can it prove to be beneficial for your industry?

If the requirement of your industry needs geosynthetics clay liners or the geonets, then it is important you are aware of what all it offers and the ways in which it will prove to be helpful.

Separation & Reinforcement of soil

It will help to increase the soil condition by road ways and laneways along with improving the slope-grade situation including the banks and hillsides.

It is done by the material having a composite feature which is helpful in retaining walls in bridges and box culverts.

Soil movement prevented & Water pressure is controlled

This will help to prevent soil movement which will allow water to move through drainage systems and fill the mode from back side which intakes more water.

These products will control the water pressure by allowing water to flow nicely from the foundation walls to drain.

These products are having different types which are mainly used in agriculture field. They are used in drainage system along with separation and reinforcement part. They are also used in woven and non-woven clothes. They are such type of material which is used for stabilization process.

- Q: 25og / m2 filter geotextile is what

- 250g / square meters of geotextile, I am specializing in production

- Q: What are the key considerations for geotextile installation in high temperature environments?

- The key considerations for geotextile installation in high temperature environments include selecting geotextiles that are resistant to thermal degradation, ensuring proper anchoring and securing of the geotextiles to prevent movement or displacement, and considering potential expansion and contraction of the geotextiles due to temperature fluctuations. Additionally, it is important to assess the long-term performance and durability of the geotextiles under high temperature conditions and to monitor their performance regularly to detect any signs of degradation or failure.

- Q: Can concrete slabs be placed directly on geotextiles?

- Huazhi geotextile material manufacturers

- Q: Application Index of Geotextile Geotextile Expressway

- Too professional, and find a happy manufacturers it

- Q: Weaving geotextile construction should pay attention to what

- Weaving geotextile construction specifications: 1, before the construction of roadbed should be integrated clean up, the surface shall not have sharp corners. 2, geotextile is best to use mechanical erection, can also be used artificial laying. When laying, it should be noted that the rough side of the singeing up, and then one end fixed with a fixed, mechanical or human tension, tensile elongation of about 1 & amp;% to 1 & amp;%, Facing front laying. The fixture includes fixed and fixed metal. Fixed nails should be used cement nails or nails, nail length 8 ~ 10cm fixed iron can be thick lmm, width 3mm of the strip. 3, weaving geotextile and the length of the long, should be used industrial sewing machine sewing, sewing method using "dow" and "seam". Suture and geotextile should have a significant color difference in order to facilitate inspection.

- Q: Can geotextiles be used in mine tailings management?

- Yes, geotextiles can be used in mine tailings management. Geotextiles are commonly used in the mining industry to help with the containment and stabilization of mine tailings. They can be used as liners or covers for tailings ponds, preventing the migration of contaminants into the surrounding environment. Geotextiles are also effective in reducing erosion and promoting vegetation growth on tailings surfaces, improving the long-term stability of these waste materials.

- Q: How do geotextiles help with soil separation in subgrade improvement projects?

- Geotextiles are used in subgrade improvement projects to separate different soil layers, preventing them from mixing. They act as a barrier, allowing water to pass through while preventing the migration of fine particles. This helps to maintain the stability and strength of the subgrade, reducing the risk of settlement and soil erosion.

- Q: Geotextile effect

- First, the drainage effect: polyester staple acupuncture geotextile has a good water conductivity, it can form a drainage channel within the soil, the soil structure of the excess liquid and gas efflux. Second, the role of contraction: When the water from the fine soil into the coarse soil layer, the use of polyester staple acupuncture geotextile good permeability and water permeability, so that water through, and effectively carrying soil particles, sand , Small stone, etc., in order to maintain the stability of soil and water engineering. Third, the isolation role: the use of polyester staple acupuncture geotextile with different physical properties of the building materials to isolate. So that two or more materials are not lost, not mixed, to maintain the overall structure and function of the material, so that the building capacity to enhance the capacity. Fourth, the role of puncture: and geomembrane combined into a composite waterproof impermeable material, play the role of anti-puncture. High tensile strength, good permeability, breathable properties, high temperature resistance, anti-freeze, anti-aging, corrosion-resistant, not moth-eaten. Polyester staple acupuncture geotextile is a widely used geosynthetics.

- Q: what is the function of geotextiles in footing any photos?

- tis like the subway put some liver in ur mouth In the middle of rush hour whore some year old mayonnaise meets yesterdays tuna It’s end of line.!!!!!!!!

- Q: Can geotextiles be used for filtration of contaminants in water?

- Yes, geotextiles can be used for filtration of contaminants in water. They are commonly used in various filtration systems, including wastewater treatment plants, to effectively remove pollutants and particles from the water. Geotextiles act as a physical barrier, allowing water to pass through while trapping and retaining contaminants, thus improving water quality.

Send your message to us

Geo Bag for Flood Controls/ Slope Protecion/Greening Environmental

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 pc

- Supply Capability:

- 500000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords