Geotextile Fabrics - Filament Spunbond Needle Punched Geotextile

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 150000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction

good flexibility, permeability, filtration, sepatation and easy for construction.

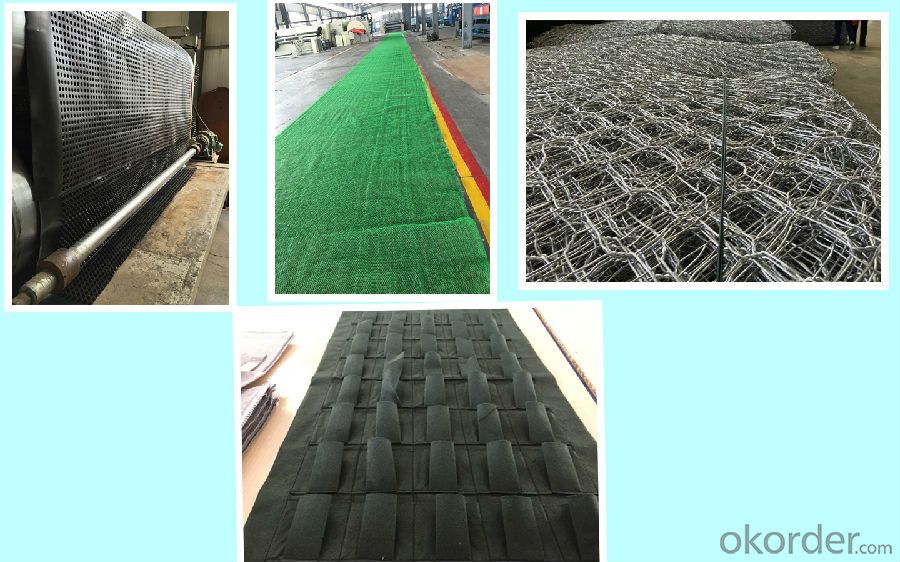

Application

CMAX Geotextile has excellent permeability, acquired, durablity, which can be widely used in railway, highway, movement hall, dams, hydraulic structures, hence hole, coastal shoal,reclamation, environmental protection and other projects.

The main products are Synthetic staple fibers needlepunched non woven geotextiles and slit and split film yarn woven geotextiles.

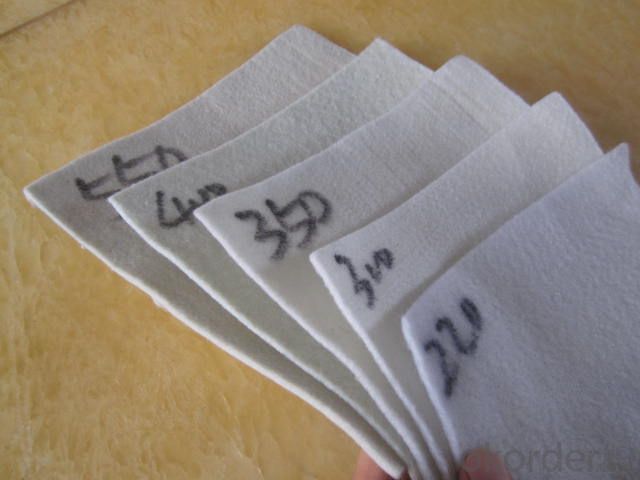

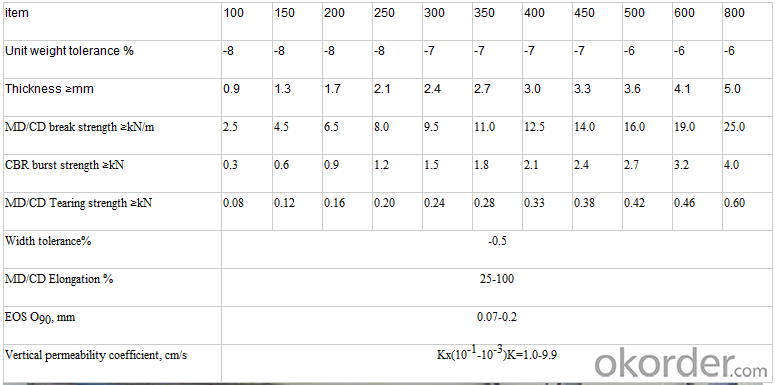

Specifications:100GSM-1500GSM

length:50m-100m

width:1m-8m

material:100%PET

Packaging Details:pp woven bags or at your request

Delivery Detail:15 days

Technical Specification

FAQ

●How long have you been in international trade and geosynthetics industry?

10-year experience in international trade.

20-year experience in geosynthetics field.

●Which payment do you accept?

For you convinience,our payment can be L/C,TT,Westunion,paypal

●Can I know the width you can produce?

Of course we can,our width can be 1 to 6m

●How will you pack the products?

Usually we pack our products by woven bags,also we can do as your requirements

●We want to make sure quality,is free sample available?

We can supply free samples if you need.

- Q: 400g / m2 two cloth a layer of water permeable geotextile technical requirements

- Two cloth a film will not be permeable, the composite film index breaking strength 5kn top broken 1.1kn tear 0.15kn peel 6n / cm or substrate fracture without stripping, the current 2008 standard weight has not been required, the original standard For not less than 360 grams

- Q: Does the color cloth be geotextile?

- Straw, sacks, stone, gravel, wood, steel, color cloth, lighting equipment, transport, alarm equipment, digging tools, lead wire, cement, soil, sand, geotextile and so on.

- Q: How do geotextiles help with soil separation?

- Geotextiles help with soil separation by providing a barrier between different soil layers or materials. They prevent the mixing and migration of soils, allowing for better drainage and filtration. Geotextiles also help to distribute loads more evenly, reducing the likelihood of soil erosion and maintaining the stability of the soil.

- Q: Can geotextiles be used in geocomposite applications?

- Yes, geotextiles can be used in geocomposite applications. Geocomposites are materials made by combining different geosynthetic components, including geotextiles, to achieve specific engineering functions. Geotextiles, due to their high tensile strength, filtration capabilities, and drainage properties, are commonly used in geocomposites to enhance the overall performance and functionality of the composite material.

- Q: What are the key factors affecting the puncture resistance of geotextiles?

- The key factors affecting the puncture resistance of geotextiles include the type and thickness of the geotextile material, the tensile strength of the fibers used, the density of the fabric, and the presence of any protective coatings or additives. Additionally, the installation and construction methods, as well as the conditions and properties of the underlying soil or material, can also influence the puncture resistance of geotextiles.

- Q: Manufacture of geotextile machinery

- Non-woven needle machine, I am specializing in the production of geotextiles

- Q: Can geotextiles be used in shoreline protection projects?

- Yes, geotextiles can be used in shoreline protection projects. Geotextiles are frequently employed to stabilize and reinforce shorelines by preventing erosion, filtering and draining water, and providing support to vegetation and soil. They are effective in controlling sediment movement, reducing wave impact, and protecting against shoreline degradation.

- Q: Will the geotechnical cloth used for highway engineering, geogrid raw materials, routine testing items, parameters which?

- Will the geotechnical cloth used for highway engineering, geogrid raw materials, routine testing items, parameters which?

- Q: With sand and gravel, geotextile do blind ditch how to construction

- Professional production geotextile manufacturers to answer

- Q: Can geotextiles be used for filtration of contaminants in water?

- Yes, geotextiles can be used for filtration of contaminants in water. Geotextiles are permeable fabrics that can effectively filter out suspended particles, sediments, and pollutants from water. They are commonly used in various applications such as wastewater treatment, erosion control, and geotechnical engineering to improve water quality by removing contaminants through filtration.

Send your message to us

Geotextile Fabrics - Filament Spunbond Needle Punched Geotextile

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 150000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords