Bj Geotextile Ltd Waterproof Geotextile Fabric Polypropylene Nonwoven Fabric for Construction

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Introduction

Geotextiles

Divider

Protect the integrity of your gabion basket installation with high-quality geotextiles between your gabion structures and the soil. We supply only the highest quality of both woven and non-woven geotextiles for gabion installations and other applications.

Geotextiles

These geotextile filter fabric materials prevent the migration of fine soils to the spaces between rock particles. The migration of fine soil into your gabion structure can cause subsidence problems below or behind the gabion structure in time if not applied correctly and will stir up problems – especially in sandy soils. Clay soils do not generally require a geotextile filter fabric as they seldom leach through the basket section. We recommend using a suitable geotextile where the gabion is in contact with earth, this will limit any movement of soils through a gabion structure. In soft soil foundations especially and wherever overlaps or joins are required, we suggest a minimum overlap of 300mm(1 ft).

We supply geotextile to all sites where gabions are used. Depending on the required structure of the gabion, we normally find that about 1-2m2 of geotextile per m3 of gabion is required

Protection: Geotextile when used as a protection layer acts as a cushioning barrier between the geosynthetic lining system and other layers of the dam or landfill cell. Generally the larger mass rolls of geotextile provide the best cushioning protection. As a protection barrier it helps prevent puncturing and leaks from external forces coming into contact with the liner.

Applications

gabions and river mattresses

roads

concrete retaining walls.

Separation

the separation of good and poor roadway layer work materials

roads over soft soils.

Roadway lining provides waterproofing qualities for layer works and wearing courses.

Drainage of

sports fields

railway tracks

behind concrete walls & embankments.

Membrane liner protection

geotextiles are permeable nonwoven fabrics used to separate, filter, reinforce, protect, or drain. Geotextiles allow filtration / separation of granular layers in roads and rail applications, used to protect membranes in landfill applications, used in coastal defence applications and used in Landscaping to protect surfaces and structures from weeds and root growth.

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

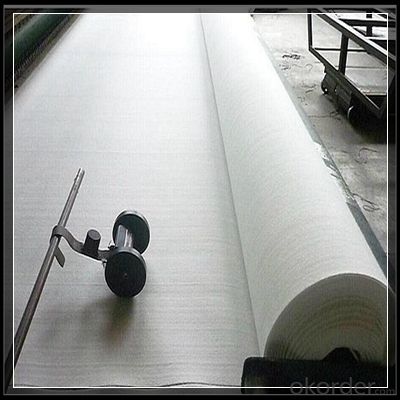

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q: After the laying of drainage board and then need to lay a layer of geotextile it?

- After the laying of drainage board and then need to lay a layer of geotextile it?

- Q: Are geotextiles resistant to rodent penetration?

- Yes, geotextiles are generally resistant to rodent penetration.

- Q: How do geotextiles help with erosion control on slopes?

- Geotextiles help with erosion control on slopes by providing a physical barrier that stabilizes the soil and prevents erosion. These synthetic fabrics are placed on the slope surface to act as a filter, allowing water to pass through while retaining soil particles. This helps to reduce the velocity of runoff, prevent soil erosion, and promote the growth of vegetation.

- Q: How are geotextiles used in retaining walls?

- Geotextiles are commonly used in retaining walls to reinforce the soil and prevent erosion. They are placed between the backfill soil and the wall, acting as a barrier to separate the soil layers and improve stability. This helps to distribute the soil pressure evenly, reducing the risk of wall failure and improving the overall strength and longevity of the retaining wall structure.

- Q: Can geotextiles be used for reinforcement of landfills?

- Yes, geotextiles can be used for the reinforcement of landfills. Geotextiles are permeable fabrics that are used to improve the stability, drainage, and filtration of soil in various applications, including landfill construction. They are often employed to prevent soil erosion and provide support to the landfill structure, enhancing its overall stability and longevity.

- Q: Geotextile tensile strength of the maximum load is generally how much

- What specifications of the geotextile? Is the filament or the short wire or the woven geotextile?

- Q: Can geotexters cover grass seeds?

- Geotextile is anti-puncture which grass can not grow out, you can use the vegetation bag ah

- Q: Geotextile cloth and no square what meaning

- Geotextile, also known as geotextile, originated in the twentieth century, the fifties. Raw materials are polyester, polypropylene, acrylic, nylon and other polymer polymer synthetic fiber. Geotextiles are woven and non-woven. Not "Square", it is divided by the manufacturing process, the use of textile technology made of geotextile called spinning, and vice versa for non-woven geotextile. Due to the low cost of spinning geotextile, the cost is slightly higher. Most of the current engineering applications are non-woven geotextiles. They have a filter, filter, isolation, reinforcement, protection, and other functions.

- Q: Geotextile puncture test standard

- Staple stitch filament piercing filament woven weaving

- Q: Water stable health with the geotextile, sticky on the water stable, how quickly cleared

- I professional production geomembrane / geotextile, the highest cost, I wish smooth

Send your message to us

Bj Geotextile Ltd Waterproof Geotextile Fabric Polypropylene Nonwoven Fabric for Construction

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords