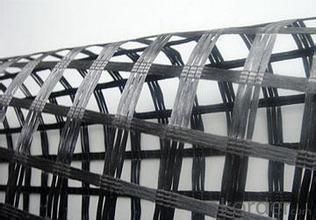

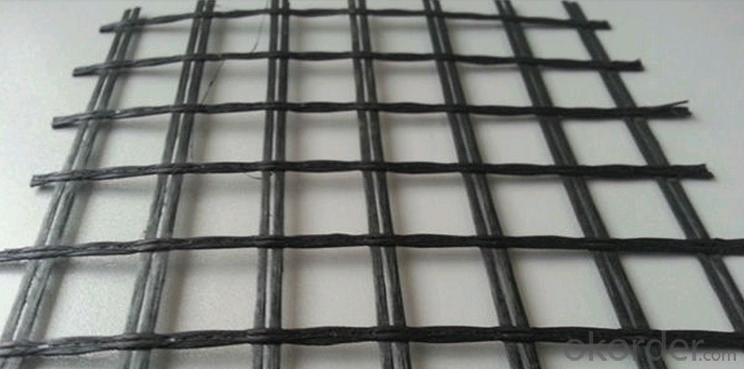

High Tensile Strength Fiberglass Geogrids and Geomembranes

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Fiberglass Geogrid with CE Certificate,Welcome choose us!

Product Description

Bitumen coated fiberglass geogrid

Fiberglass geogrid is a kind of new favorable earthwork base material to strengthen the road surface and roadbed. This product is made by weaving and covering fiberglass filament. It is featured by high vertical and horizontal tensile strength, low unit extension, high flexibility, and favorable high and low temperature resistance. The products after surface covering own the favorable property of alkali resistance and aging resistance.

| Property of Fiberglass Geogrid |

| Property | Test Method | TGSB | TGSB | TGSB | TGSB | TGSB | TGSB | TGSB | |

| 30-30 | 40-40 | 50-50 | 60-60 | 70-70 | 80-80 | 90-90 | |||

| Ultimate tensile strength(1) (kN/m) | MD | EN ISO 10139 | 30 | 40 | 50 | 60 | 70 | 80 | 90 |

| CD | 30 | 40 | 50 | 60 | 70 | 80 | 90 | ||

| Elongation at maximum load (%) | MD | 3 | |||||||

| CD | 3 | ||||||||

| Approximate mesh size(mm) | 12.7mm×12.7mm 25.4mm×25.4mm 40mm×40mm | ||||||||

| Roll Width (m) | 1m-6m | ||||||||

| Roll Length(m) | 50m-200m | ||||||||

| Property | Test Method | TGSB | TGSB | TGSB | TGSB | TGSB | TGSB | TGSB | TGSB | |

| 100-100 | 120-120 | 130-130 | 150-150 | 160-160 | 170-170 | 180-180 | 200-200 | |||

| Ultimate tensile strength(1) (kN/m) | MD | EN ISO 10139 | 100 | 120 | 130 | 150 | 160 | 170 | 180 | 200 |

| CD | 100 | 120 | 130 | 150 | 160 | 170 | 180 | 200 | ||

| Elongation at maximum load (%) | MD | 3 | ||||||||

| CD | 3 | |||||||||

| Approximate mesh size(mm) | 12.7mm×12.7mm 25.4mm×25.4mm 40mm×40mm | |||||||||

| Roll Width (m) | 1m-6m | |||||||||

| Roll Length(m) | 50m-200m | |||||||||

Packaging & Delivery

| Packaging Details: | plastic pipe + black PE membrane |

| Delivery Detail: | one 40HQ within 15 days after receipt of T/T or L/C at sight |

FAQ

1. How about the delivery time?

Lead time since receipt of 30% T/T deposit payment: 3 weeks.

2. What kind of payments does jenor support?

T/T, L/C, Cash are accepted.

3. What's are the MOQ?

We can according to your condition to set the MOQ.

And we can provide you samples for quality inspection.

4. Do you charge for the samples?

Accordeing to our company policy, the samples are freee, we only charge the freight fee. And we will return the freight fee If you set the order .

5. Can you produce the product according to customers' requirements ?

Sure, we are professional manufacturer, OEM and ODM are both welcome.

6. Can you tell me your main customers?

That's our customers' privacy, we should protect their information. At the same time, please rest assured that your information is also safe here.

- Q: What are the advantages of using geogrids in soil nailing applications?

- Geogrids offer several advantages in soil nailing applications. Firstly, they enhance the stability and strength of soil by acting as a reinforcement material. This helps to prevent slope failures and soil erosion. Secondly, geogrids improve the overall performance and lifespan of structures by providing a reliable method of soil stabilization. Additionally, they are cost-effective and relatively easy to install, making them a practical choice for soil nailing projects.

- Q: What are the factors that affect the design and selection of geogrids for geosynthetic reinforcement of slopes?

- There are several factors that affect the design and selection of geogrids for geosynthetic reinforcement of slopes. These factors include the slope angle, soil type and properties, required design life, anticipated loading conditions, and installation constraints. Additionally, factors such as cost, availability, and environmental considerations may also play a role in the selection process. Overall, a comprehensive assessment of these factors is crucial to ensure the appropriate geogrid is chosen to effectively reinforce and stabilize slopes.

- Q: How to connect the geogrid with the panel in the reinforced earth retaining wall?

- When the geogrid is laid in the curve and the corner, the adjacent earthwork grid is currently used in the reinforced earth retaining wall of the assembled panel, and the common wall of the assembled panel module will have gaps or overlaps (see Figure 1). For the outward bending of the geogrid, there are different forms such as rectangle, hexagon, shape, L shape and groove shape. Panel module will appear at the corner of the gap,In order to ensure the continuity of the reinforced soil, laying in the void design based on the engineering environment need to be flexible, prefabricated into various shapes, can provide the same type of geogrid small pieces of good, and cover all the reinforced area; for bend shop visual effect; can also use color cement, add art wall. No panel reinforcement design of geogrid, in the corner there will be some overlap in geogrid, geogrid reinforced earth retaining wall is also called anti package type or wrap-reinforcedearth retaining wall, the wall is made of mesh bags to fill the overlap coefficient of friction will be reduced, must be laying a layer of 10mm ~ 20mm thick the soil geogrid anti package into each layer of geogrid is a special connecting rod is connected with the shape of the coarse sand layer, separate the two layer of Geogrid to ensure friction resistance. As a whole, the mesh bag filling has been mixed for local growth of grass and shrub seeds, seeds, after months of growth after the formation of green ecological wall. The utility model not only protects the safety of the geogrid, but also beautifies the environment of the retaining wall project.

- Q: How do geogrids improve the performance of mechanically stabilized slopes in sandy soils?

- Geogrids improve the performance of mechanically stabilized slopes in sandy soils by providing reinforcement and increasing the stability of the soil. They help distribute tensile forces and reduce lateral movement, preventing slope failure. Additionally, geogrids enhance the bearing capacity of the soil, allowing for higher loads and reducing settlement.

- Q: What is the recommended spacing between geogrid layers?

- The recommended spacing between geogrid layers can vary depending on the specific project and soil conditions. However, in general, a spacing of about 2 to 3 feet (0.6 to 0.9 meters) is often recommended to achieve optimal reinforcement and stability.

- Q: Do geogrids enhance the load-bearing capacity of soil?

- Yes, geogrids enhance the load-bearing capacity of soil. Geogrids are typically made of high-strength materials and are designed to improve soil stability and reinforce weak or loose soils. They distribute the applied load over a wider area, reducing stress concentration and preventing soil deformation or failure. This reinforcement helps increase the load-bearing capacity of the soil, making it more suitable for various construction and engineering applications.

- Q: Can geogrids be used in retaining walls for highway projects?

- Yes, geogrids can be used in retaining walls for highway projects. Geogrids are commonly used in such projects to reinforce soil and provide stability to the retaining walls. They enhance the overall strength and durability of the walls, making them a reliable choice for highway construction.

- Q: What are the factors that affect the cost-effectiveness of geogrid-reinforced structures?

- There are several factors that can affect the cost-effectiveness of geogrid-reinforced structures. Firstly, the type and quality of geogrid used can significantly impact the overall cost. Higher quality geogrids may be more expensive but can provide better reinforcement, leading to longer-lasting and more cost-effective structures. Additionally, the design and engineering of the structure play a crucial role. Properly designed structures that consider factors such as soil conditions, loading requirements, and anticipated lifespan can ensure optimal performance and cost-effectiveness. The construction process and techniques employed also influence the cost-effectiveness. Efficient construction methods, skilled labor, and effective project management can minimize costs and maximize the durability and longevity of the geogrid-reinforced structure. Lastly, the maintenance and monitoring of the structure are essential. Regular inspections and timely repairs, if needed, can prevent costly damages and extend the lifespan of the structure, ultimately enhancing its cost-effectiveness.

- Q: What are the factors to consider when selecting geogrids for a project?

- When selecting geogrids for a project, there are several factors to consider. These include the specific application or purpose of the project, the site conditions such as soil type and slope stability, the load requirements of the project, the desired lifespan and durability of the geogrids, and the cost-effectiveness and availability of the geogrids. Additionally, it is important to consider the installation process and compatibility with other materials used in the project. By considering these factors, you can ensure that the selected geogrids will effectively meet the needs of your project.

- Q: How is the strength of a geogrid determined?

- The strength of a geogrid is determined through various laboratory tests and analysis, including tensile strength testing. This involves subjecting the geogrid to controlled loads and measuring the forces required to cause failure or deformation. Other factors such as the type of polymer used, manufacturing process, and design specifications also contribute to determining the overall strength of a geogrid.

Send your message to us

High Tensile Strength Fiberglass Geogrids and Geomembranes

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords