High Strength PP Non Woven Geotextile and Geogrid Manufacturer

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction of Geotextile

Good flexibility, permeability, filtration, sepatation and easy for construction.

Application of Geotextile

CMAX Geotextile has excellent permeability, acquired, durablity, which can be widely used in railway, highway, movement hall, dams, hydraulic structures, hence hole, coastal shoal,reclamation, environmental protection and other projects.

The main products are Synthetic staple fibers needlepunched non woven geotextiles and slit and split film yarn woven geotextiles.

Specifications:100GSM-1500GSM

length:50m-100m

width:1m-8m

material:100%PP

Packaging Details: pp woven bags or at your request

Delivery Detail: 15 days

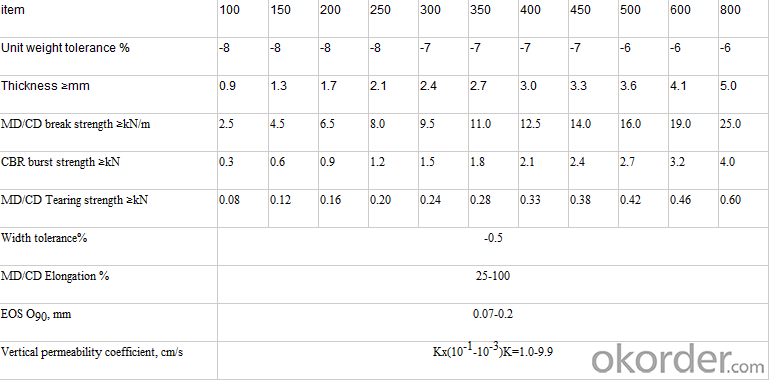

Technical Specification

FAQ

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are freee, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q: What are the key factors affecting the durability of geotextiles?

- The key factors affecting the durability of geotextiles include the material composition, UV exposure, chemical resistance, physical properties, installation and maintenance practices, and environmental conditions such as temperature and moisture levels.

- Q: Are geotextiles resistant to fire damage?

- Yes, geotextiles can be resistant to fire damage. Many geotextiles are specifically designed to have fire-resistant properties, which help prevent them from igniting or spreading flames. However, it is important to note that the level of fire resistance may vary depending on the specific type and composition of the geotextile.

- Q: How do geotextiles improve the performance of geocells?

- Geotextiles improve the performance of geocells by providing additional reinforcement and stability to the structure. They act as a barrier against soil erosion and help distribute loads evenly, increasing the overall strength and durability of the geocell system. Additionally, geotextiles prevent the mixing of different soil layers, enhancing filtration and drainage capabilities.

- Q: Can geotextiles be used in slope stabilization projects?

- Yes, geotextiles can be used in slope stabilization projects. They are commonly used to reinforce and strengthen slopes by providing soil stability, erosion control, and drainage. Geotextiles can effectively distribute loads, prevent soil movement, and increase the overall stability of slopes, making them a valuable tool in slope stabilization projects.

- Q: Can geotextiles be used in mine tailings dewatering applications?

- Yes, geotextiles can be used in mine tailings dewatering applications. Geotextiles are commonly used in this context to separate solids from liquids, allowing for the efficient dewatering of mine tailings and the retention of solid particles. They provide effective filtration and drainage, reducing the moisture content of tailings and facilitating their disposal or further processing.

- Q: Does the color cloth be geotextile?

- Straw, sacks, stone, gravel, wood, steel, color cloth, lighting equipment, transport, alarm equipment, digging tools, lead wire, cement, soil, sand, geotextile and so on.

- Q: What are the factors to consider when selecting a geotextile for a specific application?

- When selecting a geotextile for a specific application, there are several factors to consider. Firstly, the intended function of the geotextile needs to be evaluated. This includes determining whether it will be used for separation, filtration, reinforcement, or drainage purposes. Secondly, the site conditions and environmental factors such as soil type, climate, and potential chemical exposure must be taken into account. The required strength, durability, and longevity of the geotextile should also be considered. Additionally, the cost-effectiveness and availability of the specific geotextile should be assessed. Finally, the installation and maintenance requirements of the geotextile need to be evaluated to ensure proper implementation and long-term performance.

- Q: How do geotextiles contribute to the stability of railroad ballast?

- Geotextiles contribute to the stability of railroad ballast by acting as a barrier between the ballast and the underlying soil. They prevent the migration of fine particles from the soil into the ballast, reducing the risk of ballast contamination and subsequent track settlement. Geotextiles also provide reinforcement to the ballast, distributing loads more evenly and enhancing its overall stability.

- Q: Geotextile wholesale price of how much money, geotextile fabric manufacturers latest offer

- Geotextile wholesale, ranging from 5000-9000 yuan a ton. Geotextile manufacturers to answer your questions

- Q: Geomembrane upstream protective layer with what material? The Why can not you use clay?

- The protective layer should be a geotextile because the geotextile is durable than clay.

Send your message to us

High Strength PP Non Woven Geotextile and Geogrid Manufacturer

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords