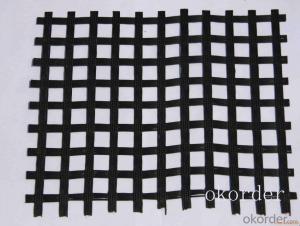

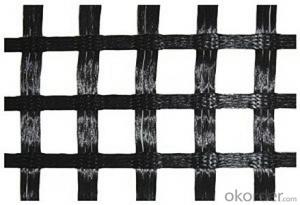

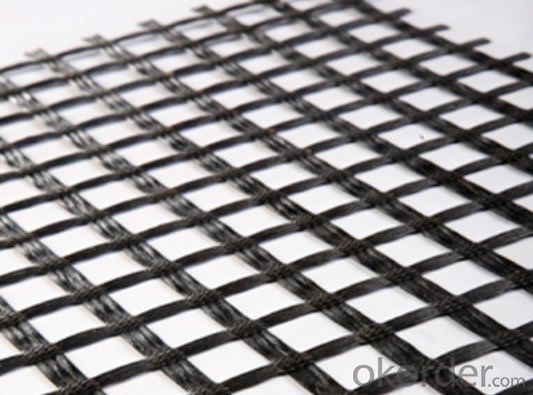

High Tensile Strength Fiberglass Geogrid Geotextile Soil Fabric for Civil Engineering

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Introduction

Type:

Geogrids

Place of Origin:

Jiangsu, China (Mainland)

Brand Name:

Lonrace

Model Number:

geogrid

Material:

Polyester

Color:

White Black Gray Etc

Tensile strength:

25Kn/m--300Kn/m

Length:

50-100m

Certification:

CE /ISO9001

Coating:

PVC

Geogrids are an economical solution for filling water stream base and creates almost an ideal surface for laying down a water resistant layer.

Slopes and subgrades with rails are a serious problem in railroad construction. Under high pressure the layers slide and deform consequently causing rail deformation, which requires closing railroad segments for a long time. Geogrid application allows carrying out comlex repair operations of the necessary road segment in shortest time (which is very essential in transportation).

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q: Are geotextiles resistant to fire damage?

- Yes, geotextiles are generally resistant to fire damage. They are often made from materials such as polypropylene or polyester, which have inherent fire-resistant properties. Additionally, geotextiles can be treated with flame retardant additives to enhance their resistance to fire damage. However, it is important to note that the level of fire resistance may vary depending on the specific type and composition of the geotextile.

- Q: Can the mortar be made directly on the composite geomembrane of the reservoir?

- Reservoirs on the composite geomembrane can be directly coated mortar composite soil film surface is geotextile can protect the PE film will not be chrome broken. South-to-North Water Diversion Project is directly in the composite geomembrane mortar.

- Q: How do geotextiles affect water quality?

- Geotextiles can positively impact water quality by acting as a filtration barrier, preventing sediment and pollutants from entering water bodies. They help in reducing erosion, promoting better stormwater management, and improving overall water clarity.

- Q: What is the effect of temperature on geotextile performance?

- The effect of temperature on geotextile performance can vary depending on the specific material and application. In general, higher temperatures can lead to increased softening and deformation of geotextiles, reducing their overall strength and stability. Extreme heat can also cause geotextiles to lose their mechanical properties and become more susceptible to degradation. On the other hand, lower temperatures may cause geotextiles to become stiff and less flexible, potentially affecting their ability to conform to the underlying soil or rock. It is important to consider the temperature range in which geotextiles will be exposed when selecting and designing their use to ensure optimal performance and longevity.

- Q: What are the different geotextile reinforcement techniques for slopes?

- Some common geotextile reinforcement techniques for slopes include slope stabilization, soil erosion control, and retaining wall construction. These techniques involve the use of geotextile materials, such as woven or non-woven fabrics, to reinforce and strengthen slopes, prevent soil erosion, and provide stability. Methods such as slope facing, slope wrapping, and soil nail reinforcement are employed to enhance the integrity and longevity of slopes in various construction and infrastructure projects.

- Q: It is best to take a picture

- Paved on the line, lap welding or with glue. The company specializes in producing geothermal geotextile, detailed advice, please see my information

- Q: How are geotextiles used in landfills?

- Geotextiles are used in landfills to help enhance the stability, drainage, and filtration of the waste disposal site. They are typically placed between the layers of soil and the landfill liner system to prevent soil erosion, control gas and liquid migration, and provide reinforcement for the overall structure.

- Q: What are the factors that affect the strength of geotextiles?

- The strength of geotextiles can be affected by several factors such as the type and quality of materials used, the manufacturing process, the weight and thickness of the geotextile, the presence of any coatings or treatments, and the installation and environmental conditions in which the geotextile is used.

- Q: Are geotextiles suitable for use in reservoir lining?

- Yes, geotextiles are suitable for use in reservoir lining. They can effectively prevent erosion and provide stability to the reservoir walls, while also allowing water to drain through. Additionally, geotextiles are durable and resistant to various environmental conditions, making them a reliable choice for reservoir lining.

- Q: Geotextile was wetted by what kind of treatment

- Geotextile was originally in the project to play a reinforced, protective, filter effect. So geotextile is not afraid of water, not afraid of wet, so do not fear wet. Damped geotextile is easy to get dirty, easy to carry. Generally dried can be used, do not need to do any treatment.

Send your message to us

High Tensile Strength Fiberglass Geogrid Geotextile Soil Fabric for Civil Engineering

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords