Foundation Geotextiles - PP/PET Needle Punched Non-Woven Geotextile

- Loading Port:

- Qingdao

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Non Woven Geotextile Specificatioin:

Properties | Unit | PET100 | PET150 | PET200 | PET250 | PET300 | PET350 | PET400 | PET450 | PET500 | PET600 | PET800 | |

Tensile Strength | MD | KN/m | 2.5 | 4.5 | 6.5 | 8 | 9.5 | 11 | 12.5 | 14 | 16 | 19 | 25 |

TD | KN/m | 2.5 | 4.5 | 6.5 | 8 | 9.5 | 11 | 12.5 | 14 | 16 | 19 | 25 | |

Tear Strength | MD | KN≥ | 0.08 | 0.12 | 0.16 | 0.2 | 0.24 | 0.28 | 0.33 | 0.38 | 0.42 | 0.46 | 0.6 |

TD | KN≥ | 0.08 | 0.12 | 0.16 | 0.2 | 0.24 | 0.28 | 0.33 | 0.38 | 0.42 | 0.46 | 0.6 | |

CBR Plunger Strength | KN≥ | 0.3 | 0.6 | 0.9 | 1.2 | 1.5 | 1.8 | 2.1 | 2.4 | 2.7 | 3.2 | 4 | |

Elongation at Yield | MD | % | 25-100 | ||||||||||

TD | % | 25-100 | |||||||||||

Hole Size | O90 | mm | 0.07-0.2 | ||||||||||

(O95) | |||||||||||||

Vertical Permeability | cm/s | k*(10-1~10-3),k=1.0~9.9 | |||||||||||

Identification Properties | |||||||||||||

Material | / | Polyester | |||||||||||

Color | / | White | |||||||||||

Thickness | mm, ≥ | 0.9 | 1.3 | 1.7 | 2.1 | 2.4 | 2.7 | 3.0 | 3.3 | 3.6 | 4.1 | 5.0 | |

Weight Unit Area | g/m² | 100 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 600 | 800 | |

Width | m | 1m-6m | |||||||||||

2. Non Woven Geotextile Introduction:

Nonwoven geotextiles are manufactured from the extrusion of polypropylene fibres which are then laid down on a manufacturing "bed" and then needle punched to entangle the fibres such that a dimensionally stable product is formed. Some additional thermal treatment is then applied to further improve the strength of the geotextile. Because of this manufacturing process non-woven geotextiles are generally best used in applications of drainage, filtration and protection

3. Non Woven Geotextile Features:

Wide-width rolls

Quality Certified

Proven for use in Main Roads works

Large range to suit the application

4. Non Woven Geotextile Application:

(1) artificial filling foundation movement of ground water.

(2) gravel filter layer surrounding the periphery of the drain pipe drain.

(3) in water conservancy projects wells, relief wells or inclined pipe filter.

(4) for retaining wall backfill reinforcement, or for anchored retaining wall panel.

(5) reinforced flexible pavements, crack repair roads, prevent the reflection cracks of pavement.

(6) in ternal vertical or horizontal drainage, dissipation of pore water pressure in soil.

(7) water impermeable geomembrane dam or embankment in the lower part of the back or the concrete.

(8) the isolation layer between the road ballast and subgrade, isolation layer or between the embankment and soft foundation.

(9) the isolation layer soil between highway, airport, railway ballast and artificial rockfill and soil fabric.

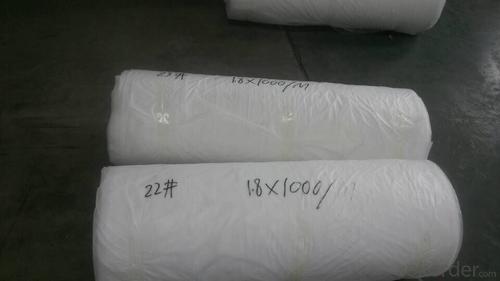

5. Non Woven Geotextile Product Show:

FAQ of our geotextile:

- Q: What can we do for the special customer?

A: Provide custom made service with customer's drawing; We make sure to provide you with the best solutions for your individual case. Whether standard items or non-standard items.

- Q: What can we supply?

A: We provide high levels of communication from start to finish.

- Q: What is our advantage?

A: Top Cemented Carbide has extensive business experience, Fast delivery and high quality.

Over the past decade a greater emphasis has been placed on the development and manufacturing of geosynthetic textiles. While the geosynthetics industry is comparatively new, it has already created products with applications in a wide range of industries including geotechnical, transportation, hydraulic, embankment management, and mining. In many cases, a single geosynthetic textile can solve or improve multiple civil engineering problems simultaneously.

The first example of a geosynthetic textile application is the use of a prefabricated pocket style vertical drain made from a nonwoven filter jacket specialized as a PVD filter material. The purpose of this product was to reduce the time needed for construction by quickly discharging water in the ground which speeds up the soil consolidation process. Overall, it proved to reduce construction time and speed up the consolidation of soft ground in a variety of different situations including road construction, the development of building sites, construction of gas and oil storage facilities, and bank revetment.

The second example of how geosynthetic textiles can provide solutions to civil engineering problems is the polyester woven geotextile mat. It is created from a high tenacity polyester filament which is highly dense. This particular geosynthetic textile has been used to reinforce soft ground and embankments, separate layers of sand and soft ground, prevent the uneven settlement of soft ground, and securing a safe path of travel for heavy equipment across soft ground.

- Q: What are the cost considerations for geotextile applications?

- The cost considerations for geotextile applications primarily include the initial material cost, installation expenses, and long-term maintenance expenses. The type and quality of geotextile chosen, along with the size and complexity of the project, can significantly impact the upfront costs. Additionally, factors such as transportation, labor, and equipment required for installation should be taken into account. Furthermore, ongoing maintenance, repair, and replacement costs should be considered to ensure the longevity and effectiveness of the geotextile application.

- Q: In ANSYS, geotextile what unit to simulate it?

- I am now doing geotextile simulation, before someone with shell63, I now use, but the shell and the physical contact I did a long time. The

- Q: Can geotextiles be used in mine tailings dam construction?

- Yes, geotextiles can be used in mine tailings dam construction. Geotextiles are often employed as a barrier or reinforcement material to enhance the stability and performance of mine tailings dams. They can provide effective filtration, separation, and erosion control, helping to improve the overall integrity and environmental sustainability of these structures.

- Q: What are the different geotextile reinforcement techniques for slopes?

- Some of the different geotextile reinforcement techniques for slopes include the use of geotextile fabrics, geogrids, and geocells. Geotextile fabrics are commonly used to stabilize slopes by providing separation and filtration of soil particles. Geogrids, on the other hand, are high-strength materials that are used to reinforce soil and increase its stability. Geocells are three-dimensional cellular structures that can be filled with soil or other materials to create a stable slope. These techniques can be used individually or in combination to provide effective reinforcement for slopes and prevent erosion.

- Q: How do geotextiles help with soil confinement in erosion control mats?

- Geotextiles help with soil confinement in erosion control mats by providing a stable and permeable layer that prevents soil erosion. They act as a barrier, holding the soil particles in place while allowing water to pass through, thereby reducing surface runoff and promoting root growth. This prevents the displacement of soil and helps in establishing vegetation, ultimately preventing erosion and improving soil stabilization.

- Q: Are geotextiles biodegradable?

- No, geotextiles are not biodegradable.

- Q: Can geotextiles be used in wetland restoration projects?

- Yes, geotextiles can be used in wetland restoration projects. They are often utilized to stabilize the soil and control erosion, which is crucial in wetland areas. Geotextiles can also help retain sediments and filter water, aiding in the establishment and maintenance of the wetland ecosystem.

- Q: Can geotextiles be used in pond liner applications?

- Yes, geotextiles can be used in pond liner applications. They are often used as a protective layer or as a separator between the soil and the pond liner material. Geotextiles can help prevent punctures or damage to the liner, enhance its durability, and improve overall performance of the pond liner system.

- Q: How do geotextiles improve drainage systems?

- Geotextiles improve drainage systems by acting as a filter between the soil and the drainage material, preventing clogging and allowing water to flow freely. They also help in distributing the water evenly, reducing erosion, and enhancing the overall efficiency and longevity of the drainage system.

- Q: Specification for Lap Length of Geotextile with Two Cloth

- 20cm I specialize in producing geotextile materials

1. Manufacturer Overview

| Location | Taian City,Shandong Province,China |

| Year Established | 2008 |

| Annual Output Value | Above US$100 Million |

| Main Markets | Africa, Oceania, North America, Western Europe, Eastern Asia |

| Company Certifications | ISO9001;IS014001 Certificate |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Qingdao Port;Tianjing Port;Shanghai Port |

| Export Percentage | |

| No.of Employees in Trade Department | 21-30 People |

| Language Spoken: | English; Chinese; |

| b) Factory Information | |

| Factory Size: | 10,000-30,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | Geotechnical Material (Geogrid,Fiberglass/Polyester Geogrid,Geocell,Geonet and Geomat,Plastic Safety Fence) |

| Product Price Range | Average |

Send your message to us

Foundation Geotextiles - PP/PET Needle Punched Non-Woven Geotextile

- Loading Port:

- Qingdao

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords