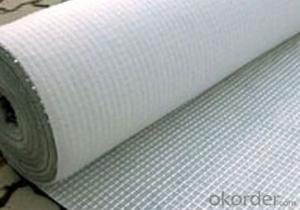

Canac Geotextile - A Geosynthetic with Excellent Characteristics

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 1500000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Advantage and function of Geotextile as one type of Geosynthetics

Good flexibility,permeability,filtration,separation and easy for construction

Filtration

The filtration layer of the dykes, river canal, seacoast, concrete slope, retaining walls. At the same time of preventing the clay granule from passing, it allows the water and the gas pass through freely.

Separation:

The isolation of the railway dregs and the roadbed, roadbed and the soft base, surface of the airdrome and parking lot and the groundsill, different dam materials. It isolates the soil and the gravel of two kinds different granule pathway from the groundsill or other buildings.

Adding muscle:

The highway, railway, soil-stone dam, breakwater, airport, backfill soil of retaining wall, slope protection, etc in which distributes the earth stress, prevents the side-displacement of the earth body and improves the earth body stability.

Protection

It prevents the dam from being washed out, protects the dam and the bottom, prevents the water and soil from being washed away.

Usage:

Used in the area of highway,railway,dam,reclamation etc.for filtration separation drainage and protection.

Size of package:

Width is 1-8m,length is 50-100m,or pack as client request

FAQ:

What is the main application of Geotextile as one type of Geosynthetics?

The main application of our Short Fiber Nonwoven Geotextile is as follows: The highway, railway, soil-stone dam, breakwater, airport, backfill soil of retaining wall, slope protection, etc.

Where is your main market?

Our main market is in Middle East, South America and some African countries.

What is your advantages for Geotextile as one type of Geosynthetics?

One of the largest manufacturer of PP Woven Geotextile for Construction

with advanced equipment, big production capacity and excellent quality.

- Q: What is the purpose of using geotextiles?

- The purpose of using geotextiles is to provide reinforcement, separation, filtration, and drainage in various civil engineering and construction applications. Geotextiles help improve soil stability, prevent erosion, control sediment migration, and enhance the overall performance and longevity of infrastructure projects.

- Q: How do geotextiles help with stabilization of railway tracks?

- Geotextiles play a crucial role in stabilizing railway tracks by providing reinforcement and separation between different layers of the track structure. They prevent the mixing of materials, such as subgrade soil and ballast, while also reducing the lateral movement of the ballast. Geotextiles enhance the overall stability and load-bearing capacity of the track, reducing maintenance needs and extending its lifespan.

- Q: Is there a geotextile for reed cultivation?

- Big slope pond words use better, need depth laying, with geomembrane

- Q: What are the considerations for geotextile selection in railroad projects?

- When selecting geotextiles for railroad projects, several considerations need to be taken into account. Firstly, the geotextile should have sufficient strength to withstand the loads and stresses imposed by train traffic. It should also possess excellent puncture resistance to ensure long-term durability. Additionally, the geotextile should have good filtration properties to prevent fine particles from entering the subgrade and causing drainage issues. It is important to consider the geotextile's permeability, as it should allow for adequate drainage to maintain the stability of the railway track. Lastly, the geotextile's compatibility with other materials used in the project, such as ballast or subgrade soils, should be evaluated to ensure proper functioning of the system.

- Q: How do geotextiles help with erosion control on slopes?

- Geotextiles help with erosion control on slopes by providing a protective layer that stabilizes the soil, prevents erosion, and promotes vegetation growth. They act as a barrier against water and wind, reducing the velocity of runoff and minimizing soil erosion. Additionally, geotextiles help to retain soil particles while allowing water to pass through, preventing the loss of soil and promoting the establishment of vegetation, which further enhances slope stability.

- Q: Can geotextiles be used for reinforcement of landfills?

- Yes, geotextiles can be used for the reinforcement of landfills. Geotextiles are permeable fabrics that are used to improve the stability, drainage, and filtration of soil in various applications, including landfill construction. They are often employed to prevent soil erosion and provide support to the landfill structure, enhancing its overall stability and longevity.

- Q: Welding of impervious geotextile

- 1. Seam processing is the key to the construction process, the general use of heat welding method, PE film surface heat treatment, so that the surface melting, and then through the pressure, so that one fusion. 2. For the laying of a good geomembrane, edge seams require no oil, water, dust and so on. 3. Before welding to adjust the seam at the two sides of the PE single film, so that a certain width of the lap, lap width is generally 6 ~ 8 cm and smooth, no wrinkles. 4. Use special welding machine for welding. Welding construction effect map:

- Q: What glue can clay stickers glue?

- Geotextiles generally do not need to glue glue, because the geotextile is made of polyester staple fiber acupuncture, the product itself has a lot of small pores, the use of glue bonding not only a waste of glue, bonding effect is not good. Geotextile in the project is generally used in the hand-type sewing machine suture, suture geotextile not only glue glue than the geotextile solid and reliable, and the construction of geotextile suture is also much higher than the construction of glue with geotextile Speed, while the cost of sewing geotextile is also much lower than the cost of glue bonding geotextile. Generally in the project to play the effect of impervious geomembrane, composite geomembrane (also known as composite geotextile) can use glue bonding. Adhesive glue can be purchased in the geomembrane manufacturer, of course, you can also buy in the local building materials market, waterproof plastic or KS geomembrane special glue. These two glue can also be used to bond geotextiles.

- Q: How do geotextiles improve the performance of landfills?

- Geotextiles improve the performance of landfills by acting as a barrier or filter to prevent the migration of fine particles and contaminants from the waste into the surrounding soil and groundwater. They also enhance the stability and structural integrity of the landfill by providing reinforcement and erosion control.

- Q: What are the different geotextile installation techniques in separation?

- There are several different geotextile installation techniques used in separation, including direct placement, trench installation, and overlapping. Direct placement involves laying the geotextile directly on the ground surface, while trench installation involves placing the geotextile in a trench dug along the separation area. Overlapping is another technique, where multiple layers of geotextile are overlapped to form a continuous barrier. These installation techniques help to prevent the mixing of different soil layers and provide effective separation between different materials.

Send your message to us

Canac Geotextile - A Geosynthetic with Excellent Characteristics

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 1500000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords