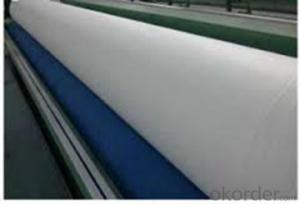

High Quality Polyester Continuous Filament Nonwoven Geotextile

- Loading Port:

- Qingdao

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 2500000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Introduction of Polyester Continuous Filament Nonwoven Geotextile:

Good flexibility, permeability, filtration, separation and easy for construction.

2. Application of Polyester Continuous Filament Nonwoven Geotextile:

Geotextile has excellent permeability, acquired, durability, which can be widely used in railway, highway, movement hall,

Dams, hydraulic structures, hence hole, coastal shoal, reclamation, environmental protection and other projects.

The main products are Synthetic staple fibers needle punched non woven geotextiles and slit and spilt film yarn woven geotextiles.

Filtration of soils in drainage applications by retaining soil particles while allowing for the free flow of water

Separation and stabilization in road and railway construction

Prevention of soil movement in erosion control measures

Cushioning and protection in many containment projects

3. Feature of Polyester Continuous Filament Nonwoven Geotextile:

1. Can withstand construction installation stresses

2. UV (Ultra Violet) Stabilized

3. High Chemical Resistance

4. Optimum Elongation

Produced from high quality fibers, Nonwoven Geotextiles are needle punched to form a strong fabric that retains its dimensional stability and is resistant to damage from construction stresses.

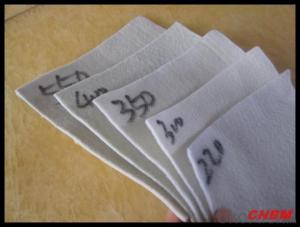

JIANYI Nonwoven Geotextiles are available in varying strengths and thicknesses to ensure appropriate material selection for your project. Below are our standard weights and sizes.

Specification of Filament Woven Geotextile:

Technical specification of short fiber needle punched non woven geotextile

No. | Item | Specification | Note | ||||||||||

100 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 600 | 800 | |||

1 | Weight Variation% | -8 | -8 | -8 | -8 | -7 | -7 | -7 | -7 | -6 | -6 | -6 |

|

2 | Thickness mm≥ | 0.9 | 1.3 | 1.7 | 2.1 | 2.4 | 2.7 | 3.0 | 3.3 | 3.6 | 4.1 | 5.0 | |

3 | Width Variation % | -0.5 | |||||||||||

4 | KN/m≥ | 2.5 | 4.5 | 6.5 | 8.0 | 9.5 | 11.0 | 12.5 | 14.0 | 16.0 | 19.0 | 25.0 | MD and TD |

5 | Elongation at Break % | 25~100 | |||||||||||

6 | CBR Mullen Burst Strength KN ≥

| 0.3 | 0.6 | 0.9 | 1.2 | 1.5 | 1.8 | 2.1 | 2.4 | 2.7 | 3.2 | 4.0 |

|

7 | Sieve Size O90 mm | 0.07~0.2 |

| ||||||||||

8 | Vertical Permeability Coefficient cm/s | K×(10ˉ1~10ˉ3) | K=1.0~9.9 | ||||||||||

9 | Tear Strength KN≥ | 0.08 | 0.12 | 0.16 | 0.20 | 0.24 | 0.28 | 0.33 | 0.38 | 0.42 | 0.46 | 0.6 | MD and TD |

- Q: How do geotextiles help in the construction of ponds and lakes?

- Geotextiles help in the construction of ponds and lakes by providing reinforcement and stability to the soil used for lining the water bodies. They act as a barrier, preventing soil erosion and controlling the movement of fine particles, ensuring the integrity and longevity of the structure. Additionally, geotextiles promote proper drainage and filtration, enhancing water quality and preventing the accumulation of excess water within the pond or lake.

- Q: Please geotextile manufacturers offer,

- Please geotextile manufacturers offer,

- Q: Can geotextiles be used in landfill lining systems?

- Yes, geotextiles can be used in landfill lining systems. They are often used as a barrier to separate the waste materials from the surrounding soil and groundwater, preventing contamination and promoting environmental protection. Geotextiles provide stability, filtration, and drainage functions in landfill lining systems.

- Q: How are geotextiles affected by temperature variations?

- Geotextiles can be affected by temperature variations in several ways. Extreme heat can cause geotextiles to expand, leading to potential deformation or loss of structural integrity. On the other hand, extreme cold can cause geotextiles to contract, potentially reducing their effectiveness and compromising their functionality. It is important to consider the temperature range and choose geotextiles that can withstand the expected variations in order to ensure their long-term performance.

- Q: What kind of geotextile is used to repair the road?

- Call one three seven to understand three one two one two to ensure that the quality of price satisfaction

- Q: Geotextile was wetted by what kind of treatment

- Geotextile was originally in the project to play a reinforced, protective, filter effect. So geotextile is not afraid of water, not afraid of wet, so do not fear wet. Damped geotextile is easy to get dirty, easy to carry. Generally dried can be used, do not need to do any treatment.

- Q: Why do you want to add 1 to the amount of geotextile

- There are overlapping area and loss, I am specializing in the production of geotextiles

- Q: Do you need to use geotextile for construction site? Mainly used where?

- Used in road, railway tunnel waterproof board behind, wrapped blind pipe, roadbed blind ditch, roadbed filter layer and so on.

1. Manufacturer Overview

| Location | Shandong, China |

| Year Established | 2001 |

| Annual Output Value | US$ 5 Million - US$ 10 Million |

| Main Markets | 20.00% North America 20.00% South America 10.00% Eastern Europe 10.00% North America 10.00% Northern Europe 10.00% South Asia 10.00% Western Europe 5.00% Africa 5.00% Mid East |

| Company Certifications | ISO9001; ISO14000 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Qingdao Port |

| Export Percentage | 21% - 30% |

| No.of Employees in Trade Department | 5-10 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | Above 30,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | Design Service Offered; Buyer Label Offered |

| Product Price Range | High; Average |

Send your message to us

High Quality Polyester Continuous Filament Nonwoven Geotextile

- Loading Port:

- Qingdao

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 2500000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords