High Quality Nonwoven Geotextile for Geotextile Egypt

- Loading Port:

- Qingdao Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 20000m2 m²

- Supply Capability:

- 30 million M2 Per Year m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

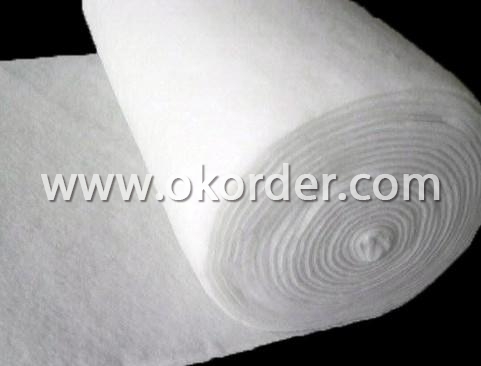

Introduction of Nonwoven Geotextile:

Good flexibility, permeability, filtration, separation and easy for construction.

Geotextile has excellent permeability, acquired, durability, which can be widely used in railway, highway, movement hall, Dams, hydraulic structures, hence hole, coastal shoal, reclamation, environmental protection and other projects. The main products are Synthetic staple fibers needle punched non woven geotextiles, we can produce with PET original and recylced material.

Specification of Nonwoven Geotextile:

Technical specification of filament spunbond needle punched geotextile in PP and PET material.

|

Item |

Value | |||||||||

|

1 |

Breaking strength |

4.5 |

7.5 |

10 |

15 |

20 |

25 |

30 |

40 |

50 |

|

2 |

Elongation at break |

40~80 | ||||||||

|

3 |

CBR Mullen Burst Strength KN≥ |

0.8 |

1.6 |

1.9 |

2.9 |

3.9 |

5.3 |

6.4 |

7.9 |

8.5 |

|

4 |

Tear strength/KN |

0.14 |

0.21 |

0.28 |

0.42 |

0.56 |

0.70 |

0.82 |

1.10 |

1.25 |

|

5 |

Sieve Size O90mm |

0.05~0.20 | ||||||||

|

6 |

Vertical Permeability Coefficient cm/s |

K×(10ˉ1~10ˉ3),k=1.0~09.9 | ||||||||

|

7 |

Thickness/mm |

0.8 |

1.2 |

1.6 |

2.2 |

2.8 |

3.4 |

4.2 |

5.5 |

6.8 |

|

8 |

Width Variation % |

-0.5 | ||||||||

|

9 |

Weight Variation % |

-5 | ||||||||

- Q: What are the different methods of geotextile installation?

- There are several different methods of geotextile installation, including trenching, direct placement, sewing, stapling, and adhesive bonding. Trenching involves excavating a trench and placing the geotextile fabric in it before backfilling. Direct placement involves simply unrolling and placing the geotextile on the desired surface. Sewing involves stitching the geotextile to another fabric or material, providing additional strength. Stapling involves using staples or nails to secure the geotextile to the ground or other surfaces. Adhesive bonding involves using specialized adhesives to attach the geotextile to the desired substrate. The choice of installation method depends on the specific project requirements and the type of geotextile being used.

- Q: Can geotextiles be used in mining tailings management?

- Yes, geotextiles can be used in mining tailings management. Geotextiles are widely used in mining operations to improve the stability and containment of tailings, reduce erosion, and enhance filtration and drainage. They can be employed in various applications such as lining tailings storage facilities, constructing embankments, and creating barriers to prevent seepage. By providing reinforcement and filtration, geotextiles help in managing and mitigating the environmental impact associated with mining tailings.

- Q: Pudong Chuansha where to sell geotextiles

- Geotextile, also known as geotextile, it is made of synthetic fiber through acupuncture or woven from the permeability of geosynthetics. Geotextile is a new material geosynthetics which one, the finished product for the cloth, the general width of 4-6 meters, the length of 50-100 meters. Geotextile is divided into a spinning geotextile and non-woven filament geotextile. Use geotextile, letter, welcome

- Q: What are the advantages of using geotextiles in landfill lining systems?

- There are several advantages of using geotextiles in landfill lining systems. Firstly, geotextiles act as a barrier, preventing the leakage and migration of hazardous substances from the landfill into the surrounding environment, thus protecting groundwater and adjacent ecosystems. Secondly, geotextiles enhance the stability and integrity of the landfill by providing reinforcement and preventing soil erosion, which can lead to slope failure and instability. Additionally, geotextiles offer excellent filtration properties, allowing for the efficient drainage of liquids within the landfill, reducing the buildup of pore pressure, and improving the overall performance of the system. Lastly, geotextiles are durable, resistant to chemical degradation, and have a long lifespan, making them a cost-effective and sustainable solution for landfill lining systems.

- Q: What are the different geotextile tensile strength test methods?

- Some of the different geotextile tensile strength test methods include the grab test, strip test, wide-width strip test, and trapezoidal tear test. These methods are used to measure the resistance of geotextiles to pulling forces and provide valuable information about their overall strength and durability.

- Q: What are the specifications for geotextiles in civil engineering projects?

- Geotextiles used in civil engineering projects have specific specifications that include factors such as weight, tensile strength, permeability, and durability. The weight of the geotextile is typically measured in grams per square meter (gsm) and can vary depending on the specific application. Tensile strength refers to the material's ability to resist breaking under tension and is measured in units like kilonewtons per meter (kN/m). Permeability is a crucial factor, as geotextiles should allow water to pass through while preventing the movement of soil particles. Lastly, durability is essential to ensure the geotextile can withstand the environmental conditions it will be exposed to, such as UV exposure or chemical resistance.

- Q: How do geotextiles help in gas venting?

- Geotextiles help in gas venting by allowing the passage of gases through their porous structure while preventing the migration of soil particles. These textiles are used as a barrier or filter to control the movement of gases, such as methane, in areas where gas buildup can be hazardous, such as landfills or contaminated sites. The geotextiles allow the gas to escape, reducing the risk of explosions or other safety hazards, while still providing stability and support to the surrounding soil.

- Q: What is the meaning of geotextile anchoring?

- Geotextile anchorage: is the geotextile in the construction of civil engineering construction in the slope of the fixed, to prevent the geotextile movement.

- Q: Are geotextiles suitable for use in mining tailings containment?

- Yes, geotextiles are suitable for use in mining tailings containment. Geotextiles offer excellent filtration properties, high tensile strength, and durability, making them effective in preventing soil erosion and controlling water flow within tailings containment areas. They can also aid in the separation of different layers of tailings, improving the stability and overall performance of the containment system.

- Q: Geotextile filter layer set which quota

- Filter cloth, monofilament filter cloth, polypropylene filter cloth, nylon green monofilament

1. Manufacturer Overview

| Location | Shandong, China |

| Year Established | 2001 |

| Annual Output Value | US$ 5 Million - US$ 10 Million |

| Main Markets | 20.00% North America 20.00% South America 10.00% Eastern Europe 10.00% North America 10.00% Northern Europe 10.00% South Asia 10.00% Western Europe 5.00% Africa 5.00% Mid East |

| Company Certifications | ISO9001; ISO14000 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Qingdao Port |

| Export Percentage | 21% - 30% |

| No.of Employees in Trade Department | 5-10 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | Above 30,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | Design Service Offered; Buyer Label Offered |

| Product Price Range | High; Average |

Send your message to us

High Quality Nonwoven Geotextile for Geotextile Egypt

- Loading Port:

- Qingdao Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 20000m2 m²

- Supply Capability:

- 30 million M2 Per Year m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords