Geotextile UPSC Anti-Skid Needle Punched Non Woven Geotextile Cmax

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 12000 m²

- Supply Capability:

- 600000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction of Geotextile

Good flexibility, permeability, filtration, sepatation and easy for construction.

Application of Geotextile

CMAX Geotextile has excellent permeability, acquired, durablity, which can be widely used in railway, highway, movement hall, dams, hydraulic structures, hence hole, coastal shoal,reclamation, environmental protection and other projects.

The main products are Synthetic staple fibers needlepunched non woven geotextiles and slit and split film yarn woven geotextiles.

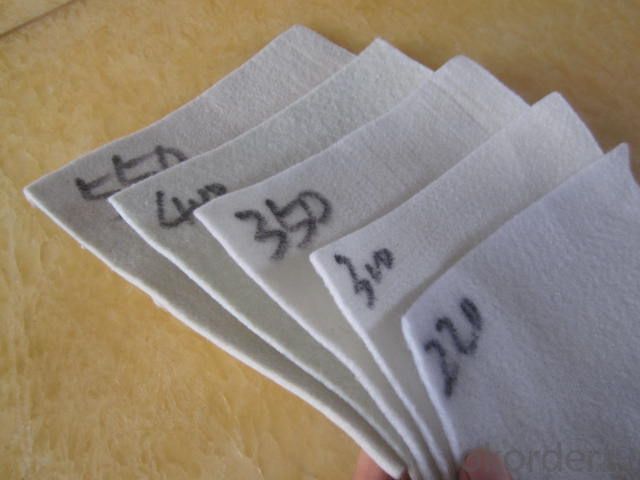

Specifications:100GSM-1500GSM

length:50m-100m

width:1m-8m

material:100%PET

Packaging Details: pp woven bags or at your request

Delivery Detail: 15 days

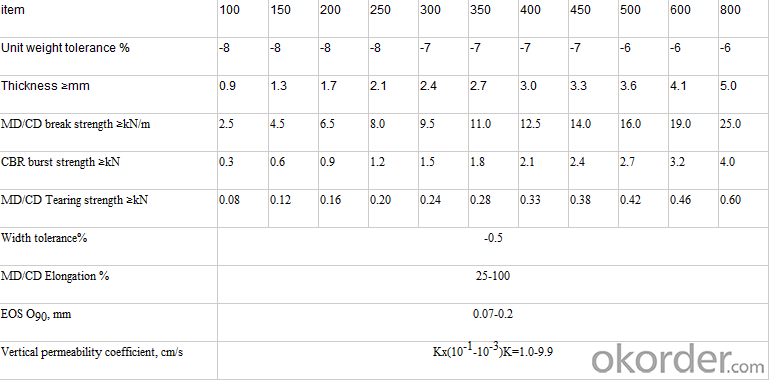

Technical Specification

Packing

FAQ

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are freee, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

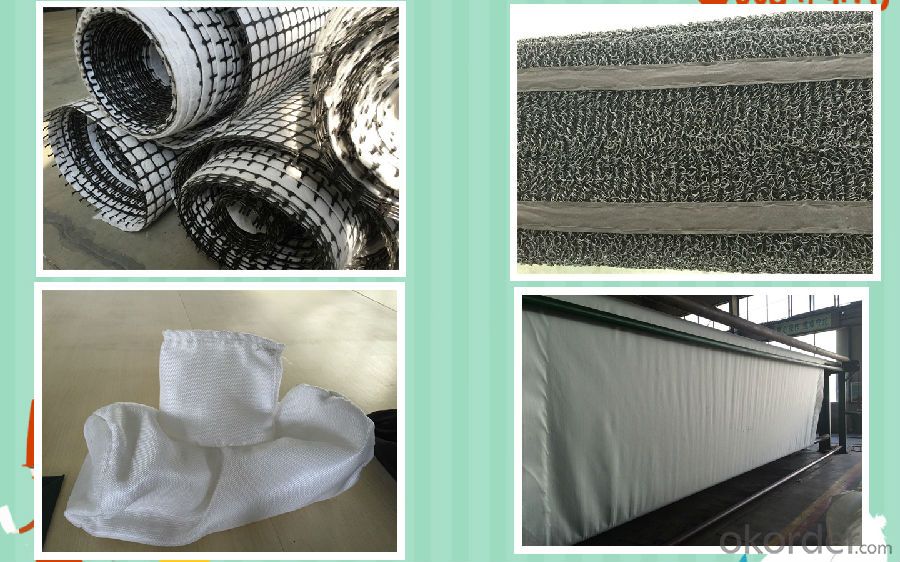

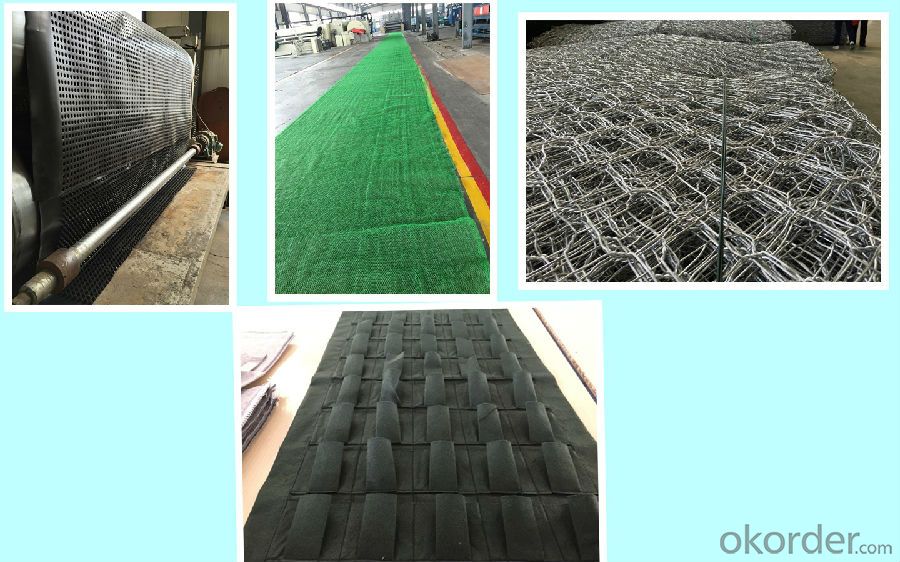

A: Yes, please check the pictures:

- Q: What are the advantages of using geotextiles in stormwater management?

- Geotextiles offer several advantages in stormwater management. Firstly, they act as a filter, preventing fine particles and pollutants from entering the stormwater system, thus improving water quality. Secondly, geotextiles provide erosion control by stabilizing soils and preventing soil erosion during heavy rainfall events. Additionally, these materials aid in water infiltration, allowing stormwater to be absorbed into the ground instead of overwhelming drainage systems. Lastly, geotextiles are cost-effective and easy to install, making them a practical and efficient solution for stormwater management.

- Q: Please geotextile manufacturers offer,

- Please geotextile manufacturers offer,

- Q: Related applications, product applications, industrial structure and distribution

- Road cloth, that is, geotextile, also known as geotextile, it is made of synthetic fibers through the needle or woven from the permeability of geosynthetics. Geotextile is a new material geosynthetics which one, the finished product for the cloth, the general width of 4-6 meters, the length of 50-100 meters. Geotextile is divided into a woven geotextile and non-woven geotextile. Geotextile with excellent filtration, drainage, isolation, reinforcement, protection, with a light weight, high tensile strength, good permeability, high temperature, anti-freeze, anti-aging, corrosion resistance characteristics. The application of geosynthetics originated in the 1950s, the domestic geotextile is one of the national eight five plan, China promulgated in 1998, "geosynthetics staple acupuncture non-woven geotextile" (GB / T -1998) standard, the current geotextile has been widely used in many areas. Geotextile mainly in the following three series: 1, acupuncture non-woven geotextile, specifications 100g / m2-600g / m2 between any choice, the main raw material is the use of polyester staple fiber or polypropylene staple fiber, made by acupuncture, Uses are: river, sea, lake embankment slope protection, reclamation, wharf, ship lock flood control and other projects, is through the filter to play a soil and water conservation and effective way to prevent piping. 2, acupuncture non-woven and PE film composite geotextile, specifications have a cloth a film, two cloth a film, the largest width of 4.2 meters The main raw material is to use polyester staple fiber non-woven, PE film through the composite , The main purpose is anti-seepage, apply to railways, highways, tunnels, subways, airports and other projects. 3, non-woven and woven composite geotextile, a variety of non-woven and polypropylene filament woven composite, non-woven and plastic woven composite, suitable for foundation reinforcement, adjust the permeability coefficient of the basic engineering facilities.

- Q: Is there a filament geotextile manufacturer? Introduce the main performance ah

- Our road embankment reinforcement project, for example, the construction of the road first focus on the quality of the road followed by the use of these two problems, and Hongxiang new material filament geotextile just to solve. In order to improve the smoothness of the road to prevent the occurrence of reflective cracks and play the role of waterproof layer. Laying and impregnating the asphalt between the base layer and the surface layer to form the filament geotextile - asphalt interlayer. You can see the specific understanding of the user name

- Q: Tunnel without sand concrete, geotextile, seepage blind pipe construction sequence

- In accordance with the order of seawater blind pipe geotextile sandless concrete, I specialize in producing geotextile materials

- Q: How do geotextiles help in reducing the risk of soil liquefaction?

- Geotextiles help in reducing the risk of soil liquefaction by providing reinforcement and stabilizing the soil. They act as a barrier to prevent the movement of water within the soil, reducing the buildup of excess pore water pressure. This pressure is a major factor contributing to soil liquefaction during earthquakes. By promoting drainage and improving soil strength, geotextiles help to mitigate the potential for liquefaction and increase the overall stability of the soil.

- Q: Are geotextiles resistant to extreme weather conditions?

- Yes, geotextiles are designed to be resistant to extreme weather conditions. They are manufactured using high-quality materials that can withstand harsh weather elements such as heavy rains, strong winds, and intense sunlight. Geotextiles are specifically engineered to provide long-lasting performance and durability even in extreme weather conditions.

- Q: Are geotextiles suitable for use in chemical containment facilities?

- Yes, geotextiles are suitable for use in chemical containment facilities. Geotextiles provide a reliable barrier against chemical leaks and can effectively prevent the migration of contaminants. They are designed to withstand chemical exposure and offer excellent resistance to corrosion and degradation, making them an ideal choice for use in such facilities.

- Q: Can geotextiles be used in erosion control in river channel stabilization?

- Yes, geotextiles can be used in erosion control in river channel stabilization. Geotextiles are engineered fabrics that can be placed in river channels to prevent soil erosion and stabilize the riverbanks. They help in reducing the velocity of water flow, trapping sediment, and promoting vegetation growth, thereby effectively controlling erosion in river channels.

- Q: How do geotextiles help in stabilizing slopes for pipeline construction?

- Geotextiles help in stabilizing slopes for pipeline construction by providing reinforcement and erosion control. They are placed on the slope surface to prevent soil erosion and stabilize the soil particles. The geotextiles act as a barrier, allowing water to drain while retaining soil particles, thus reducing the risk of slope failure.

Send your message to us

Geotextile UPSC Anti-Skid Needle Punched Non Woven Geotextile Cmax

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 12000 m²

- Supply Capability:

- 600000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords