High Tensile Strength Fiberglass Geogrids for Soil Reinforcement

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50000 m²

- Supply Capability:

- 2000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Fiberglass Geogrid with High Tensile Strengthen

Description Of Fiberglass Geogrid with High Tensile Strengthen:

1. A kind of planar mesh material using alkali-free fiberglass yarn as base body and

then coated with high quality modified asphalt.

2. Warp knitted with oriental structure which gives full play of yarn strength and improves its mechanical property to make the product high tensile, tearing and creep-resistant.

3. Coated with asphalt making full protection of the fiberglass matrix and greatly

improving its wear and shear resistance.

4. Having a good performance in pavement strengthening, track cracking and solving

difficulties of strengthening the bituminous pavement.

Main Features of Fiberglass Geogrid with High Tensile Strengthen:

1. Light weight, high tensile strength, high modulus, low elongation and good toughness.

2. Corrosion resistance, no long-term creep, long life span.

3. Good physical and chemical stability and good thermal stability.

4. Resistant to fatigue cracking, high-temperature track and low temperature shrinkage cracking.

5. Delaying and decreasing crack reflection.

Specifications of Fiberglass Geogrid with High Tensile Strengthen:

Tensile Strength (KN) | Warp | >30 | >50 | >60 | >80 | >100 | >120 | >150 | >200 |

Weft | >30 | >50 | >60 | >80 | >100 | >120 | >150 | >120 | |

Elongation(%) | <4< p=""> | <4< p=""> | <4< p=""> | <4< p=""> | <4< p=""> | <4< p=""> | <4< p=""> | <4< p=""> | |

Mesh Size(mm) | 25.4*25.4 | 25.4*25.4 | 25.4*25.4 | 25.4*25.4 | 25.4*25.4 | 25.4*25.4 | 25.4*25.4 | 25.4*25.4 | |

Elastic Modulus | 76 | 76 | 76 | 76 | 76 | 76 | 76 | 76 | |

Width(m) | 1~6 | 1~6 | 1~6 | 1~6 | 1~6 | 1~6 | 1~6 | 1~6 | |

Length(m) | 50~300 | 50~300 | 50~300 | 50~300 | 50~300 | 50~300 | 50~300 | 50~300 | |

Temperature Resistant(℃) | -100~280 | -100~280 | -100~280 | -100~280 | -100~280 | -100~280 | -100~280 | -100~280 | |

Resin Content (%) | 18~20 | 18~20 | 18~20 | 18~20 | 18~20 | 18~20 | 18~20 | 18~20 | |

Glue Type | Bitumen PVC SBR soakage | Bitumen PVC SBR soakage | Bitumen PVC SBR soakage | Bitumen PVC SBR soakage | Bitumen PVC SBR soakage | Bitumen PVC SBR soakage | Bitumen PVC SBR soakage | Bitumen PVC SBR soakage | |

Applications of Fiberglass Geogrid with High Tensile Strengthen:

1. Maintenance of old asphalt road reinforcement of asphalt pavement.

2. Converting old cement concrete road into composite road.

3. Restraining reflection cracking caused by block shrinkage.

4. Preventing and controlling the cracking caused by new and old combination and uneven settlement.

5. Road extension.

6. Reinforcement of soft soil foundation and overall strength of roadbed.

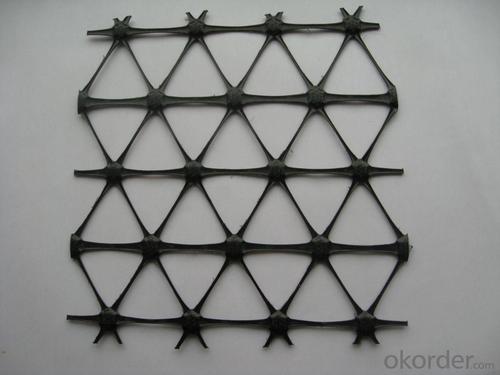

IMages of Fiberglass Geogrid with High Tensile Strengthen:

FAQ of Fiberglass Geogrid with High Tensile Strengthen:

1. What are we supplying?

We are specialized in producing Geosynthetic materials, like Geogrid Series, HDPE Geocell, Geonet, Geotextile, Geomat, Tri Denmensional Composite Grainage Geonet, and Geomembrane Series.

.

2. How Many years experience do we have?

We have been exported to more than 20 countries in the past 15 years.

3. How long do we usually reply your request?

We always reply our customer within 24 hours.

- Q: Geotextile manufacturers which good? Where is the best geotextile, geotextile manufacturers

- Needled nonwoven geotextile:The specification of 100g/m2-600g/m2 between any choice, the main raw materials is the use of polyester staple fiber or polypropylene staple fiber, made by acupuncture method, the main purpose is to: slopeprotection River, sea, Lake embankment, land reclamation, flood control engineering, dock lock, is an effective way to maintain and prevent piping through the return to the soil and water filter.

- Q: How much is the tensile strength of geogrid???????

- Divided into three categories: the overall plastic stretch: two-way products: 15KN--50KN one-way products: 50KN---300KN

- Q: What are the differences between three different types of geogrids?Unidirectional geogrid, two-way geogrid plastic, geogrid, warp knitted geogrid and fiberglass geogridWhich is the best place in Guangzhou geogrid Zhejiang geogrid in Tianjin?

- Steel plastic geogrid, fiberglass geogrid, polyester geogrid, etc., according to the direction of stress is divided into one-way

- Q: Do geogrids affect soil drainage?

- Yes, geogrids can affect soil drainage. Geogrids are typically used to reinforce soil and improve its stability. While they do not directly impact soil drainage, their installation can alter the flow of water through the soil. If not properly designed, geogrids can obstruct the natural drainage paths, leading to potential issues with water buildup. Therefore, it is important to consider the design and placement of geogrids to ensure proper soil drainage.

- Q: What is the typical thickness of a geogrid?

- The typical thickness of a geogrid can vary depending on its intended use, but it typically ranges from 0.5 to 3 millimeters.

- Q: What are the geotechnical testing items for Subgrade?

- Longitudinal and transverse tensile strength and elongation

- Q: Performance parameters of steel plastic geogrid

- The ultimate tensile strength of KN/m type per meter per meter of elongation 100 times per meter KN/m% freeze thawing ultimate tensile strength

- Q: What are the factors that affect the quality of glass fiber reinforced plastic grid

- The first is glass fiber. Glass steel fiber can improve the tensile strength and the elastic modulus of FRP pultruded grating plate, but also can reduce shrinkage, improve the heat deformation temperature and low temperature impact strength, therefore is glass steel grille pultrusion cover the main load-bearing part.

- Q: Who knows how much the staggered distance of the lap joint is

- The staggered distance of the lap joint shall not be less than 300 mm. The concrete specification (geotextile laid overlapping: when) using geotextile as filter layer, should be laid in place in the bottom and sides of the trench wall, soil and reserve covering the top required fabric, straighten ride close to the lower layer, all vertical or horizontal joints should be staggered alternately. The lap length shall not be less than 300MM.A grille is made of polypropylene, PVC polymer and thermoplastic or molded by two-dimensional grid or a certain height of the three-dimensional mesh screen, when used as a civil engineering, called geogrid.

- Q: What is the meaning of reinforced subgrade? Is there a geogrid type on the road?

- Yes. But not necessarily the design of geogrid.

Send your message to us

High Tensile Strength Fiberglass Geogrids for Soil Reinforcement

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50000 m²

- Supply Capability:

- 2000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords