Stainless Steel Sheets NO.1 Finish Grade 304 Price

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 2000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

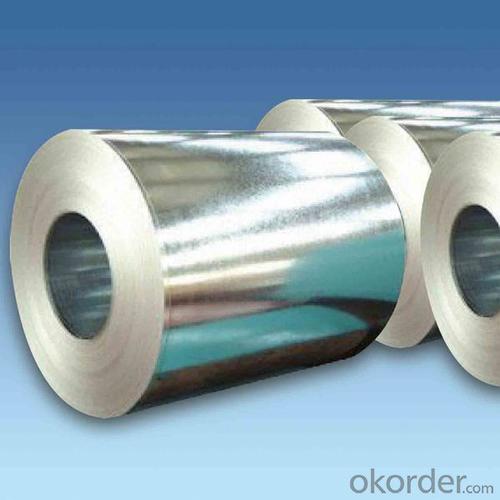

Products Description for Stainless Steel Coils/Sheets:

Product | stainless steel coils/plates/sheets | ||

Discharge Port | Any Port, China | ||

Size | Coils | Cold Rolled: | Thickness0.3-8mm,Width:280-2100mm |

Hot Rolled : | Thickness3-14mm,Width:650-2100mm | ||

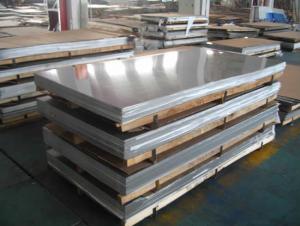

Plates | Thickness2-80mm,Width:1500-3000mm | ||

Coil Weight | About 20 Tons | ||

Grade | 201,202,304/304L/304H,316/316L/316H,321/H,310S,409/L,430 etc. | ||

Technique | Hot Rolled/Cold Rolled | ||

Finish | 2B, BA, 2D, No1, No2, No4,NO.8,SB etc | ||

Edge | Mill Edge / Slitting Edge | ||

Package | In bundles, or as customer's requirement | ||

Place of Origin | Made in China | ||

MOQ | 20 Tons | ||

Description for Stainless Steel Coils/Sheets:

Article | 304 cold rolled stainless steel coil |

Surface | 2b, No.1 |

type | coil |

Thickness | 0.3-8mm |

Usage | construction, machine building, container manufaturing, shipbuilding, chemical industry, kitchen decoration |

Parking | kraft paper wooden packing or as your requirement |

Payment | Small quantity (within total $2000.00) T/T at sight, 30% in advance , 70% after receiving the B/L copy. Large quantity L/C at sight. |

Delivery Time | 30-40 days after received the deposit |

Application of Stainless Steel Coils

(1)Boiler heat exchanger,

(2)Chemical industries,

(3)Hardware fields,

(4)Construction material,

(5)Kitchen utensils,

(6)Building construction,

(7)Medical equipment,

(8)Chemical tank,

(9)Pipe etc

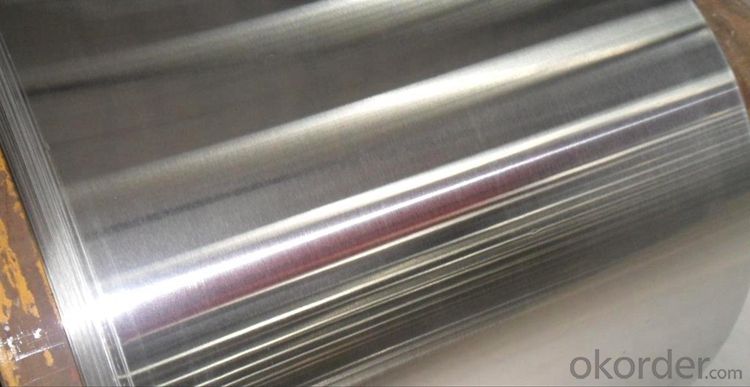

Detail picture for Stainless Steel Coils/Sheets

Packaging & Delivery for Stainless Steel Coils/Sheets:

Packaging Detail | Standard export packing or following customer's demand |

Delivery Time | Within 30-40 days after deposit or according to the order quantity |

FAQ for Stainless Steel Coils/Sheets:

Q:What are the advantages of your company ?

A: We have many professionals, technical personnel, more competitive prices and best after-dales service than other stainless steel companies.

Q:Can you arrange the shipment ?

A: Sure we can help you with the shipment. We have forwarders who have cooperated with us for many years.

- Q: How thick is 10gauge in stainless steel plate?

- To understand the word "guage", is to understand the 202304201 steel, or the same number of sandpaper. Such as steel No. 304, sandpaper 360.

- Q: Can stainless steel sheets be cold rolled?

- Indeed, it is possible to cold roll stainless steel sheets. The cold rolling process involves passing a stainless steel sheet through a sequence of rollers at ambient temperature, leading to a decrease in thickness and an augmentation in both hardness and strength. By employing this technique, one can create stainless steel sheets with accurate measurements and impeccable surface textures. Cold rolling is widely utilized in the production of stainless steel sheets, catering to diverse sectors including automotive parts, kitchen devices, and architectural constructions.

- Q: What specifications do stainless steel plates have?

- This is not specified. Do you want to make 201 or 304?. You can measure the size of the bag you want. Double fold (usually 10MM), such as length, width, and thickness of the package. Go and ask someone to do it for you. If fitted, use a glass or spot weld.

- Q: Can stainless steel sheets be used for swimming pool installations?

- Yes, stainless steel sheets can be used for swimming pool installations. Stainless steel is a highly durable and corrosion-resistant material, making it suitable for use in swimming pools. It is resistant to rust, stains, and chemicals commonly found in pool water, making it a reliable choice for long-term use. Stainless steel sheets are often used for pool walls, floors, and other structural components because they can withstand the harsh conditions associated with pool environments. Additionally, stainless steel has a sleek and modern appearance, adding to the overall aesthetics of the pool.

- Q: What are the different types of embossed patterns available for stainless steel sheets?

- There are several different types of embossed patterns available for stainless steel sheets, including diamond, quilted, linen, leather, and checker plate patterns.

- Q: Can stainless steel sheets be used in food processing?

- Food processing can make use of stainless steel sheets. They are commonly chosen in the food industry because of their advantageous properties. One crucial property is their resistance to corrosion, which is highly important in food processing environments where contact with water, chemicals, and food is frequent. Stainless steel sheets are also non-reactive, meaning they do not interact with food or impact its taste, thus making them a safe option for food processing equipment. Moreover, stainless steel is easy to clean and maintain, making it ideal for maintaining the high levels of hygiene required in food processing facilities. Its durability and strength ensure that it can withstand the demanding nature of food processing operations. Overall, stainless steel sheets are the preferred choice in the food industry for their suitability in food processing applications.

- Q: Can stainless steel sheets be used for elevator ceiling panels?

- Yes, stainless steel sheets can be used for elevator ceiling panels. Stainless steel is a popular choice for elevator interiors due to its durability, aesthetic appeal, and ease of maintenance. Stainless steel sheets offer a sleek and modern look to elevator ceilings, and they are resistant to corrosion, stains, and scratches. Additionally, stainless steel is hygienic and can be easily cleaned, making it a suitable material for elevator ceilings, where cleanliness and hygiene are important factors.

- Q: What are the advantages and disadvantages of net drawing stainless steel users?

- Brushed stainless steel refers to: stainless steel surface like filamentous texture, this is only a stainless steel processing technology. The surface is Matt, and carefully look at the above there is a trace of texture, but can not touch it.

- Q: How are stainless steel sheets finished?

- To achieve different appearances and textures, there are various ways to finish stainless steel sheets. The most common techniques for finishing stainless steel sheets are as follows: 1. Mill Finish: Stainless steel sheets have a dull, non-reflective surface with visible grain lines as a result of the manufacturing process. This is the standard finish when the sheets are first produced. 2. Brushed Finish: Also known as satin finish, this involves brushing the surface of the stainless steel with an abrasive material to create a consistent, fine grain appearance. It produces a smooth and matte finish, which is often preferred for aesthetic reasons. 3. Mirror Finish: This finish creates a highly reflective and mirror-like surface on the stainless steel sheets. It is achieved by progressively polishing the surface with finer abrasive materials until a smooth and reflective finish is achieved. 4. Embossed Finish: This technique involves impressing a pattern or design onto the surface of the stainless steel sheets. Heat and pressure are used to create raised or recessed patterns, adding texture and visual interest to the sheets. 5. Bead Blasted Finish: Fine glass beads or other abrasive materials are used to blast the surface of the stainless steel sheets. This creates a uniform, matte appearance with a slightly textured finish. 6. PVD Coating: Physical Vapor Deposition (PVD) is a process where a thin layer of metal or alloy is vaporized and deposited onto the surface of the stainless steel sheets. This coating enhances the appearance of the sheets, offering various colors and finishes such as gold, bronze, or black. In summary, the choice of finish for stainless steel sheets depends on the desired aesthetic, functionality, and application of the material. Each finish has its own unique characteristics, allowing for versatility and customization in various industries, including architecture, interior design, automotive, and more.

- Q: Can stainless steel sheets be used for cryogenic storage containers?

- Indeed, cryogenic storage containers can make use of stainless steel sheets. Stainless steel is renowned for its exceptional strength, durability, and corrosion resistance, making it perfectly suitable for cryogenic purposes. Moreover, stainless steel exhibits low thermal conductivity, effectively reducing heat transfer from the environment to the stored contents. This particular characteristic is vital in cryogenic storage as it helps maintain the necessary low temperatures for preserving materials like liquefied gases or biological samples. In summary, stainless steel sheets serve as a dependable and widely employed material for cryogenic storage containers.

Send your message to us

Stainless Steel Sheets NO.1 Finish Grade 304 Price

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 2000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords