Woven Geotextile Specifications for Geotextile Non Woven PP Earthwork for Road and Railway

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 2000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

Type: GeotextilesPlace of Origin: Hebei, China (Mainland)Brand Name: CMAX GeotextileModel Number: HT3258Geotextile Type: Non-Woven GeotextilesColor: Black , white , greyApplying Area: Road,River bank , lake dam, mine remainings, reservior, tunnelManufacturing method: Nonwoven / wovenWidth: within 8mWeight: 100-1500gsmLength: 50-100m/roll;at requestName: PP Geo Fabric Rolls/ geotxtile used in garbage burying field

Packaging & Delivery

Packaging Details:pallet and design the packing according to client's requestsDelivery Detail:15-30days after received deposit

Landfill Geotextile Polyurea

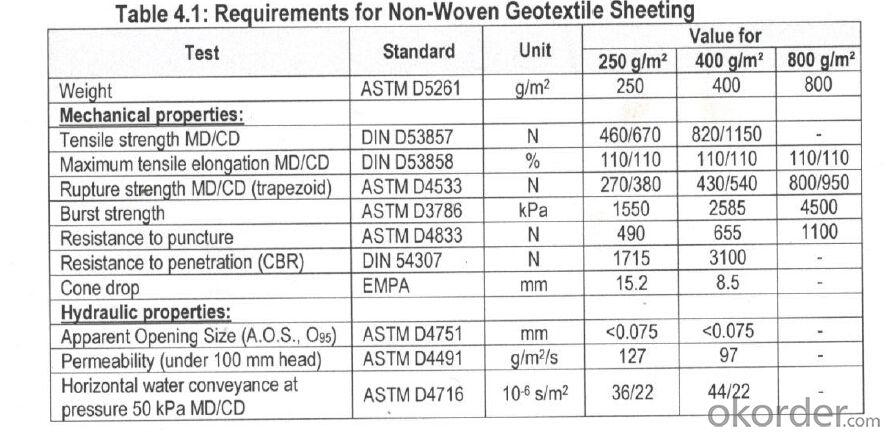

1. Geotextile Specifications

1) Weight / Mass: 100g/m2-1500g/m2 .

2) Width: Within 8 m (1m-8m as request ).

3) Length: 50m-100m/roll (as request).

4) Material: PP / PET .

5) Certificate: CE/ISO9001/ISO14001

6) Manufacturing method: nonwoven / woven.

2. nonwoven geotextile Features :

1) Staple fibers geotextile:

The geotextile is made of polypropylene staple fibers on cross-laying equipment and needle punched equipment.

It owns the advantages of acid and alkali resistance, erosion resistance, aging resistance, large strength, stable size, good filtrability etc.

2) Filament geotextile:

Filament geotextile has features as follows: High strength, good capacity of elongation and high biology tolerance, alkali tolerance, acidity tolerance, weather resistance good filtration and fine drainage capacity etc. Also it is of low cost, easy in construction and use effects.

3. geotextile Applications

1) Filtration geotextile:

The filtration layer of the dykes, river canal, seacoast, concrete slope, retaining walls. At the same time of preventing the clay granule from passing, it allows the water and the gas pass through freely.

2) Separation geotextile:

The isolation of the railway dregs and the roadbed, roadbed and the soft base, surface of the airdrome and parking lot and the groundsill, different dam materials. It isolates the soil and the gravel of two kinds different granule pathway from the groundsill or other buildings.

3)Adding geotextile:

The highway, railway, soil-stone dam, breakwater, airport, backfill soil of retaining wall, slope protection, etc in which distributes the earth stress, prevents the side-displacement of the earth body and improves the earth body stability.

4) Protection geotextile:

It prevents the bank from being washed out, protects the bank and the bottom, prevents the water and soil from being washed away.

Application

It widely used in civil environmental engineering and construction projects . Such as railway , highway , road , landfill , gymnasium , dike , marine works , tunnel , tide flat , reclamation and environment protection projects.

They use include:

u Filtration of soils in drainage applications by retaining soil particles while allowing for the free flow of water

u Separation and stabilization in road and railway construction

u Prevention of soil movement in erosion control measures

u Cushioning and protection in many containment projects

Service we can provide

1. Good after sales service: Any small problem happening will be solved at the most prompt time;

2.We have many years of experience, we have specializing in fastener;

3. Specifications list is available upon your request

4. Welcome to send enquiry,we will reply soon.If you want to know more,pls feel free to contact us.

5. Prompt shipment with professional documents

6. Packing as your request, with photo before shipment

7. High quality and competitive price

- Q: How do geotextiles contribute to soil consolidation?

- Geotextiles contribute to soil consolidation by providing reinforcement and stabilization. They act as a barrier that prevents soil particles from being washed away by water or eroded by wind. This helps in maintaining the integrity and compactness of the soil, leading to improved consolidation and increased load-bearing capacity. Additionally, geotextiles can also distribute the applied load more evenly, reducing differential settlement and promoting a more uniform consolidation process.

- Q: How do geotextiles contribute to the stability of road embankments?

- Geotextiles contribute to the stability of road embankments by providing reinforcement and separation. They act as a barrier between the road base and the underlying soil, preventing mixing and maintaining the integrity of the embankment. Additionally, geotextiles enhance drainage by allowing water to flow through while preventing the loss of soil particles. This helps to prevent erosion and maintain the stability of the embankment over time.

- Q: Are geotextiles suitable for use in geocells?

- Yes, geotextiles are suitable for use in geocells. Geotextiles provide reinforcement, filtration, and erosion control within geocell systems, enhancing their overall performance. The geotextiles used in geocells help distribute loads, prevent soil erosion, and promote proper drainage, making them a valuable component in geocell applications.

- Q: How are geotextiles used in shoreline protection?

- Geotextiles are used in shoreline protection to stabilize and reinforce the soil, preventing erosion and maintaining the integrity of the shoreline. They are typically installed as a barrier between the soil and water, acting as a filter to allow water to pass through while retaining the soil. This helps to reduce wave energy and promote sediment accumulation, ultimately protecting the shoreline from erosion caused by currents, tides, and storms.

- Q: What are the fire resistance properties of geotextiles?

- Geotextiles generally possess good fire resistance properties. They are typically made from synthetic materials such as polypropylene or polyester, which have inherently high melting points and low flammability. Additionally, geotextiles often undergo treatments to enhance their fire resistance, such as the addition of flame retardant chemicals. These properties help geotextiles withstand exposure to fire and prevent their contribution to the spread of flames. However, it is important to note that the specific fire resistance properties can vary depending on the type and composition of the geotextile.

- Q: How do geotextiles help with groundwater protection?

- Geotextiles function as a barrier or filter that helps protect groundwater by preventing the infiltration of contaminants into the underground water sources. They aid in separating different layers of soil and preventing the mixing of pollutants with the groundwater, thereby safeguarding the quality and purity of water resources.

- Q: Unit of the quality of 400 geotextile piercing strong is generally how much? Hurry more

- First, geotextile polyester staple fiber geotextile (PET) and polyester filament geotextile two. Two kinds of geotextile anti-puncture strong (should be CBR burst strong) different. Polyester staple geotextile in accordance with the national standard GB / T-2008 standard implementation, 400g GB polyester staple geotextile CBR burst strength ≥ 2.1KN. Polyester filament geotextile in accordance with the national standard GB / T-2008 standard implementation, 400g GB polyester filament geotextile CBR burst strength ≥ 39KN. 400g GB polyester staple geotextile longitudinal and horizontal tear strength ≥ 0.33KN, 400g GB polyester filament geotextile longitudinal and horizontal tear strength ≥ 0.56KN.

- Q: How do geotextiles help in erosion control?

- Geotextiles help in erosion control by acting as a barrier between the soil and water, preventing erosion by filtering and stabilizing the soil. They provide reinforcement and support to the soil, reducing the impact of water flow and preventing the loss of soil particles. Additionally, geotextiles promote vegetation growth by retaining moisture, enhancing root development, and protecting newly seeded areas from wind and water erosion.

- Q: What are the standards and regulations governing geotextiles?

- Geotextiles are governed by various standards and regulations to ensure their quality, performance, and safety. Some of the key standards include ASTM D4355, which defines the classification system for geotextiles based on their functions and characteristics, and ASTM D4595, which specifies the test methods for determining the properties of geotextiles. Additionally, regulations such as the American Association of State Highway and Transportation Officials (AASHTO) and the Federal Highway Administration (FHWA) provide guidelines for the use of geotextiles in transportation projects. These standards and regulations aim to promote consistency, reliability, and effectiveness in the use of geotextiles for various applications.

- Q: Can geotextiles be used for filtration of contaminants in water?

- Yes, geotextiles can be used for filtration of contaminants in water. They are commonly used in various filtration systems, including wastewater treatment plants, to effectively remove pollutants and particles from the water. Geotextiles act as a physical barrier, allowing water to pass through while trapping and retaining contaminants, thus improving water quality.

Send your message to us

Woven Geotextile Specifications for Geotextile Non Woven PP Earthwork for Road and Railway

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 2000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords