Geotextile 400g Filament Spunbond Needle Punched Best Price

- Loading Port:

- Qingdao

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction

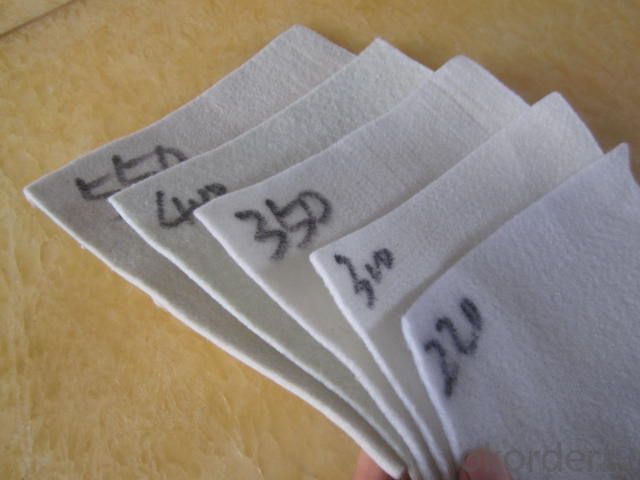

Filament needle punched nonwoven geotextile using all new polyester resin spunbonded continuous filament needle punched geotextiles are manufactured by the extrusion of fibers which are then laid down on a manufacturing "bed" and then needle punched from both top and bottom to entangle the fibers to produce a dimensionally stable geotextile.

Specification

Material | PP (polypropylene), Virgin PET(polyester), recycle PET |

Techinics | thermally bonded and needle punched |

Specification | Usually 100g/m2 to 1200g/m2 or as your demand |

Width | 1m to 6m(as you demand) |

Length | 100m(as you demand) |

Colour | White,Green,Grey,Black.etc |

Packing | PE film and woven cloth, paper core inside if you ask. |

FAQ of our geotextile:

- Q: What can we do for the special customer?

A: Provide custom made service with customer's drawing; We make sure to provide you with the best solutions for your individual case. Whether standard items or non-standard items.

- Q: What can we supply?

A: We provide high levels of communication from start to finish.

- Q: What is our advantage?

A: Top Cemented Carbide has extensive business experience, Fast delivery and high quality.

- Q: What are the specifications for geotextiles in subsurface drainage projects?

- The specifications for geotextiles in subsurface drainage projects typically include factors such as the material type, weight, thickness, and permeability. These specifications ensure that the geotextile is capable of effectively filtering water and preventing soil particles from clogging the drainage system. Additionally, the specifications may outline requirements for strength, durability, and UV resistance to ensure the geotextile can withstand the environmental conditions in the subsurface drainage projects.

- Q: Are geotextiles suitable for use in underground drainage systems?

- Yes, geotextiles are suitable for use in underground drainage systems. Geotextiles are permeable fabrics that can be used to separate, filter, reinforce, and drain soil in a drainage system. They help prevent the clogging of pipes and provide additional stability and longevity to the overall system.

- Q: Can geotextiles be used for reinforcement of embankments?

- Yes, geotextiles can be used for reinforcement of embankments. Geotextiles are commonly used in civil engineering projects to improve the stability and strength of embankments. They provide reinforcement by distributing and dissipating forces, preventing soil erosion, and enhancing the overall performance and longevity of the embankment structure.

- Q: How do geotextiles help with separation and stabilization in railroads?

- Geotextiles are used in railroads to effectively separate and stabilize different layers of the track system. By providing a strong barrier between the subsoil and the ballast layer, geotextiles prevent the mixing of materials and maintain the integrity of the track structure. This separation helps to evenly distribute loads and prevent differential settlement. Additionally, geotextiles contribute to stabilization by enhancing the overall strength and stiffness of the track system, reducing the potential for deformation and improving the long-term performance of the railroads.

- Q: What are the key considerations for geotextile installation in high water flow areas?

- Some key considerations for geotextile installation in high water flow areas include selecting a geotextile material with a high flow rate to allow for effective water drainage, ensuring proper anchoring and securing of the geotextile to prevent displacement, conducting thorough site investigations and assessments to determine the appropriate installation method and design, and monitoring the performance of the geotextile over time to identify any maintenance or repair needs. Additionally, considering the environmental conditions and potential impact on the geotextile's durability is crucial in high water flow areas.

- Q: How do geotextiles help with asphalt overlay?

- Geotextiles help with asphalt overlay by providing reinforcement and stabilization to the underlying soil, preventing it from shifting or settling. This helps to increase the longevity and durability of the asphalt overlay, as well as reducing the occurrence of cracks and potholes.

- Q: Can geotextiles be used for soil stabilization?

- Yes, geotextiles can be used for soil stabilization. Geotextiles are commonly used to reinforce and stabilize soil by providing strength, preventing erosion, and promoting drainage. They are often used in various civil engineering applications such as road construction, embankments, and retaining walls to improve the stability and longevity of the soil.

- Q: Can geotextiles be used in canal lining applications?

- Yes, geotextiles can be used in canal lining applications. Geotextiles provide effective erosion control, drainage, and filtration properties, making them suitable for lining canals to prevent soil erosion and improve water flow.

- Q: How do geotextiles help with soil stabilization in construction sites?

- Geotextiles help with soil stabilization in construction sites by reducing soil erosion, improving soil structure, and enhancing the overall stability of the construction area. They are placed beneath the soil surface to prevent the migration of fine particles, distribute loads evenly, and provide reinforcement to the soil. This helps in controlling soil movement, increasing the bearing capacity of the ground, and ultimately ensuring a more secure and durable construction foundation.

- Q: Can geotextiles be used in green roof drainage systems?

- Yes, geotextiles can be used in green roof drainage systems. Geotextiles are commonly used as a filtration layer in green roof systems to prevent clogging of the drainage layer. They help in retaining water and reducing runoff, thereby improving the overall drainage efficiency of the green roof.

1. Manufacturer Overview

| Location | Taian City,Shandong Province,China |

| Year Established | 2008 |

| Annual Output Value | Above US$100 Million |

| Main Markets | Africa, Oceania, North America, Western Europe, Eastern Asia |

| Company Certifications | ISO9001;IS014001 Certificate |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Qingdao Port;Tianjing Port;Shanghai Port |

| Export Percentage | |

| No.of Employees in Trade Department | 21-30 People |

| Language Spoken: | English; Chinese; |

| b) Factory Information | |

| Factory Size: | 10,000-30,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | Geotechnical Material (Geogrid,Fiberglass/Polyester Geogrid,Geocell,Geonet and Geomat,Plastic Safety Fence) |

| Product Price Range | Average |

Send your message to us

Geotextile 400g Filament Spunbond Needle Punched Best Price

- Loading Port:

- Qingdao

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords