Manta Geotextil Para Techos - 100g-1000g Continuous Polyester Filament Spunbond Nonwoven Geotextile

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

100g-1000g Continuous Polyester Filament Spunbond Needle Punched Nonwoven Geotextile

1.Product Specification for 100g-1000g Continuous Polyester Filament Spunbond Needle Punched Nonwoven Geotextile

Geotextile type: non-woven

Weight: 100gsm-1000gsm

Width: 1.0m-7.0m

Length: 50m-100m or as request

Color: White, black or as request

Certificates: ISO9001, ASTM, CE, SGS

2.Technical Sheet for 100g-1000g Continuous Polyester Filament Spunbond Needle Punched Nonwoven Geotextile

Item | Value | ||||||||||||||||||||

Nominal Breaking strength | 4.5 | 7.5 | 10 | 15 | 20 | 25 | 30 | 40 | 50 | ||||||||||||

1 | Breaking strength (MD/CD)/(KN/m) | 4.5 | 7.5 | 10 | 15 | 20 | 25 | 30 | 40 | 50 | |||||||||||

2 | Elongation at Break (MDD/CD) /% | 40~80 | |||||||||||||||||||

3 | CBR Mullen Burst Strength/KN | 0.8 | 1.6 | 1.9 | 2.9 | 3.9 | 5.3 | 6.4 | 7.9 | 8.5 | |||||||||||

4 | Tear strength/KN | 0.14 | 0.21 | 0.28 | 0.42 | 0.56 | 0.70 | 0.82 | 1.10 | 1.25 | |||||||||||

5 | Sieve Size O90/mm | 0.05~0.20 | |||||||||||||||||||

6 | Vertical Permeability Coefficient cm/s | K*(10-1~10-3) Among K=1.0-9.9 | |||||||||||||||||||

7 | Thickness /mm | 0.8 | 1.2 | 1.6 | 2.2 | 2.8 | 3.4 | 4.2 | 5.5 | 6.8 | |||||||||||

8 | Width Variation % | -0.5 | |||||||||||||||||||

9 | Weight Variation % | -5 | |||||||||||||||||||

3.Application for 100g-1000g Continuous Polyester Filament Spunbond Needle Punched Nonwoven Geotextile

1,Filter of embankment and slope protection of water conservancy projects, channel isolation, seepage control.

2,Isolate the basis of highway, railway, airport runway, filter, drainage, slope, retaining wall reinforcement, drainage and pavement.

3,Soft ground treatment of port engineering, beach, beach, harbor wharf and breakwater reinforcement and drainage.

4,Landfills, isolation of the ash dam, mine tailings dam in thermal power plants, the seepage control

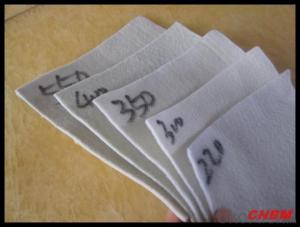

4.Product Show for 100g-1000g Continuous Polyester Filament Spunbond Needle Punched Nonwoven Geotextile

5.RFQ

1) What's your payment terms?

L/C at sight, T/T are accepted

2) What's your package?

Per roll with one woven bag or as your request

3) What's your delivery time?

One week after prepayment received

- Q: How can the geotextile extension of 65 to do the following

- I professional production geotextile geomembrane and other geotechnical materials, wish smooth

- Q: What are the key factors affecting the durability of geotextiles?

- The key factors affecting the durability of geotextiles include the quality of the materials used, exposure to environmental conditions such as UV radiation and moisture, the level of mechanical stress and loading, and the installation and maintenance practices.

- Q: How are geotextiles used in retaining walls?

- Geotextiles are used in retaining walls to provide reinforcement and stability. They act as a separator between the soil and the retaining wall, preventing soil erosion and promoting drainage. Additionally, geotextiles help to distribute the pressure exerted by the soil, reducing the risk of wall failure.

- Q: How do geotextiles prevent soil contamination?

- Geotextiles prevent soil contamination by acting as a barrier between the soil and potential contaminants, such as pollutants or waste materials. They prevent the migration of contaminants into the soil by providing a physical barrier that filters out harmful substances and allows only clean water to pass through. Additionally, geotextiles can enhance the stability and strength of the soil, reducing the risk of erosion and preventing the spread of contaminated soil to surrounding areas.

- Q: What are the advantages of using geotextiles in wetland restoration projects?

- There are several advantages of using geotextiles in wetland restoration projects. Firstly, geotextiles provide effective erosion control by stabilizing the soil and preventing it from washing away during heavy rainfall or flooding. This helps in maintaining the wetland's structure and preventing further degradation. Secondly, geotextiles act as a barrier, preventing the migration of harmful substances such as pollutants or excess nutrients from adjacent areas into the wetland, thus protecting its ecological integrity. Additionally, geotextiles can enhance vegetation growth by retaining moisture in the soil, promoting root development, and preventing weed growth. This ultimately contributes to the overall success of wetland restoration efforts.

- Q: What are the specifications for geotextiles in gas venting projects?

- The specifications for geotextiles in gas venting projects typically include factors such as the material's permeability, strength, and durability. The geotextile should have a high permeability to allow gas to pass through while preventing the migration of fine particles. It should also possess adequate strength to withstand the gas pressure and potential stresses. Additionally, the geotextile should exhibit durability to withstand environmental conditions and maintain its functionality over time.

- Q: Can geotextiles be used in agricultural drainage systems?

- Yes, geotextiles can be used in agricultural drainage systems. They are commonly used as a filter fabric to prevent soil particles from clogging drainage pipes while allowing water to pass through. Geotextiles help improve the efficiency and longevity of agricultural drainage systems by preventing soil erosion and maintaining the proper flow of water.

- Q: High-speed rail 2-type sliding layer to use two cloth a film, geotextile wool surface close to the concrete, but in the geotextile between the smooth and matte surface there is controversy, both sides of the geotextile is fluffy soft , A smooth side of some hard, hope to understand the master to answer the hairy side is smooth or matte surface? Thank you more

- Hairy side is smooth, do when the hair surface paste concrete, on the film and then meet the smooth surface, that is, both sides of the hairy folder to the middle of the structure, or not play the role of sliding

- Q: How do geotextiles help with moisture management in construction projects?

- Geotextiles help with moisture management in construction projects by acting as a barrier that allows water to pass through while preventing soil erosion. They can be used to separate different layers of soil or aggregates, preventing the mixing of fine and coarse materials and ensuring proper drainage. Additionally, geotextiles can help control groundwater by providing filtration and reducing the risk of water accumulation, ultimately enhancing the overall stability and durability of construction projects.

- Q: Welding geotextile how to apply the mattress on or below

- Geotextile does not need welding, geotextile is geotextile, the product itself exists gaps and pores, in the project mainly play a filter, filter, reinforcement, the role of protection, can not achieve the role of anti-seepage. Generally only need to suture on it. Composite geotextile need to be welded, composite geotextile, also known as composite geomembrane, by the geomembrane through a series of production processes, the upper and lower sides were combined on the geotextile production. In the production process in each roll of composite geotextile of the four sides will be set aside 10-20cm width of the welding edge. Welding construction only need to weld the edge of the geomembrane welding, welding edge of the geotextile suture can be. Geomembrane need to be welded, geomembrane is divided into smooth geomembrane and rough geomembrane (matte geomembrane), smooth geomembrane without the need for direct laying of welding on it. Rough surface geomembrane is generally covered with wool up, welding need to remove the surface and then welding.

1. Manufacturer Overview

| Location | 示范:Hebei, China |

| Year Established | 示范:1997 |

| Annual Output Value | 示范:Above US$50 Million |

| Main Markets | 30.00% South America; 20.00% North America; 15.00% Eastern Europe; 15.00% Southeast Asia; 10.00% South Asia; 5.00% Southern Europe; 5.00% Africa |

| Company Certifications | ISO 9001:2008 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin;Qingdao;Shanghai |

| Export Percentage | |

| No.of Employees in Trade Department | 21-50 People |

| Language Spoken: | English;Chinese |

| b) Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | Above 12 |

| Contract Manufacturing | OEM Service Offered;Design Service Offered |

| Product Price Range | High;Average |

Send your message to us

Manta Geotextil Para Techos - 100g-1000g Continuous Polyester Filament Spunbond Nonwoven Geotextile

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords