Geotextile And Geomembrane

Geotextile And Geomembrane Related Searches

Geotextil Y Geomembrana Geomembrane Geotextile Geomembranas Y Geosinteticos Geomembranes Geomembrane Technologies Textured Geomembrane Geomembrane Materials Application Of Geomembrane Terram Geotextile Membrane Geotextile Woven Dan Nonwoven Geotextile Mesh Geogrid With Geotextile Geomembrane Containment Geomembrane Fabric Geomembrane Material Geocomposite Membrane Geomembrane Systems Plastic Geomembrane Conductive Geomembrane Geomembrane Properties Geomembrane Machine Permeable Geomembrane Properties Of Geomembrane Geomembrane Products Reinforced Geomembrane Geotextile Membrane Suppliers Prefabricated Geomembranes Geomembrane Thickness High Strength Geotextile Pre-Seamed GeomembranesGeotextile And Geomembrane Supplier & Manufacturer from China

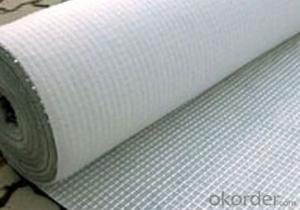

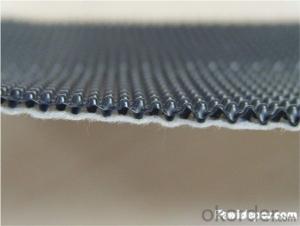

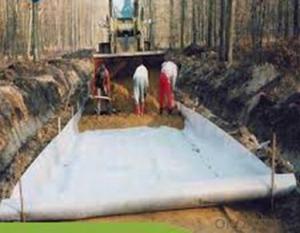

Geotextile and geomembrane are two essential products in the field of civil engineering and construction. Geotextiles are permeable fabrics made from synthetic materials like polyester, polypropylene, or polyethylene, which are used to separate, filter, reinforce, or protect soil. Geomembrane, on the other hand, is a flexible and impermeable material, typically made from high-density polyethylene (HDPE), used for waterproofing, containment, and environmental protection. These products are widely utilized in various applications such as road construction, landfill liners, erosion control, and water management systems.Geotextile and geomembrane play a crucial role in enhancing the performance and durability of civil engineering projects. They are used to prevent soil erosion, improve the stability of slopes, and reduce the permeability of soil layers. In addition, they help in the containment of hazardous waste, providing a barrier against the migration of contaminants. The use of these products ensures the sustainability and long-term effectiveness of construction projects, making them indispensable in the industry.

Okorder.com is a leading wholesale supplier of geotextile and geomembrane products, offering a vast inventory to cater to the diverse needs of clients. With a strong commitment to quality and customer satisfaction, Okorder.com provides reliable and cost-effective solutions for various construction and environmental protection projects. Their extensive range of geotextile and geomembrane products ensures that clients can find the perfect fit for their specific requirements, making Okorder.com a trusted partner in the industry.

Hot Products