Geotextile Gazon for Construction - Geosynthetics

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 1500000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Advantage and function of Geotextile as one type of Geosynthetics

Good flexibility,permeability,filtration,separation and easy for construction

1) Filtration

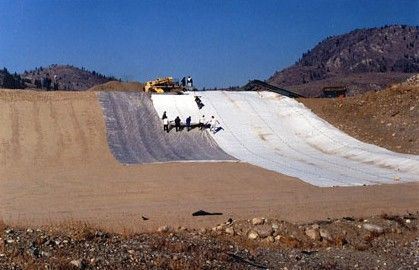

The filtration layer of the dykes, river canal, seacoast, concrete slope, retaining walls. At the same time of preventing the clay granule from passing, it allows the water and the gas pass through freely.

2 )Separation:

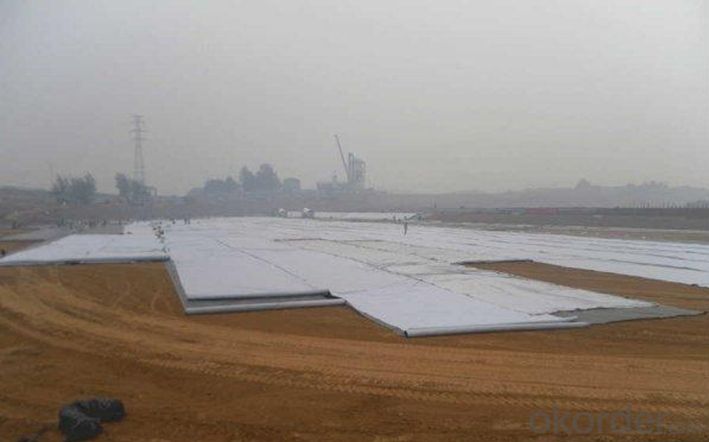

The isolation of the railway dregs and the roadbed, roadbed and the soft base, surface of the airdrome and parking lot and the groundsill, different dam materials. It isolates the soil and the gravel of two kinds different granule pathway from the groundsill or other buildings.

3) Adding muscle:

The highway, railway, soil-stone dam, breakwater, airport, backfill soil of retaining wall, slope protection, etc in which distributes the earth stress, prevents the side-displacement of the earth body and improves the earth body stability.

4 )Protection

It prevents the dam from being washed out, protects the dam and the bottom, prevents the water and soil from being washed away.

2.Usage:

Used in the area of highway,railway,dam,reclamation etc.for filtration separation drainage and protection.

3.Size of package

Width is 1-8m,length is 50-100m,or pack as client request

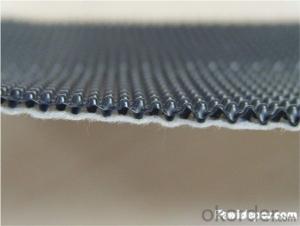

2.Specifications of Geotextile as one type of Geosynthetics

1) Weight / Mass: 100g/m2-1500g/m2

2) Width: Within 8 m (1m-8m)

3) Length: 50m-100m/roll (as request)

4) Material: PP / PET

5) Color: Black , white , grey and other color

6) Certificate: CE/ISO9001 , ISO14001

7) Manufacturing method: nonwoven / woven

8) The Biggest geotextile manufacturer/factory in China for many years

3. Technical Data Sheet of Geotextile as one type of Geosynthetics

PET continuous filament spunbond needle punched nonwoven geotextile(representative average data.) | |||||||||

Test Item/Unit/No. | HY100 | HY150 | HY200 | HY250 | HY300 | Test Method | |||

Mechanical Properties | |||||||||

Tensile Strength | CD | kn/m | 4.8 | 8.3 | 10.9 | 14.5 | 18 | ASTM D 4595 | |

MD | 7 | 12 | 14 | 18 | 22 | ||||

Elongation at maximum load | CD | % | 65 | 64 | 63 | 62 | 61 | ||

MD | 64 | 63 | 62 | 61 | 60 | ||||

Grab Strength | CD | kn ≥ | 0.36 | 0.58 | 0.87 | 1.08 | 1.35 | ASTM D 4632 | |

MD | 0.42 | 0.78 | 1.07 | 1.33 | 1.6 | ||||

Grab Elongation | CD | % | 55 | 55 | 59 | 59 | 60 | ||

MD | 50 | 50 | 51 | 51 | 53 | ||||

Trapezoidal Tear | CD | kn ≥ | 0.16 | 0.23 | 0.31 | 0.39 | 0.46 | ASTM D 4533 | |

MD | 0.245 | 0.31 | 0.42 | 0.46 | 0.55 | ||||

Burst Strength-CBR plunger method | kn ≥ | 0.85 | 1.47 | 2.3 | 2.8 | 3.3 | ASTM D 6241 | ||

Puncture resistance | n ≥ | 220 | 320 | 430 | 540 | 650 | ASTM D 4833 | ||

Mullen Burst | Mpa | 1.2 | 1.8 | 2.3 | 2.8 | 3.3 | ASTM D 3786 | ||

Cone drop resistance(hole-Φ)Dynamic perforation diameter | mm | 34 | 30 | 26 | 22 | 19 | BS EN 918-1996 | ||

Hydraulic Properties | |||||||||

Flow Rate,Q100 | L/s/m² | 200 | 210 | 180 | 150 | 140 | ASTM D 4491 | ||

Permeability | cm/s | 0.48 | 0.43 | 0.39 | 0.36 | 0.34 | |||

Apparent Opening Size O95 | mm ≤ | 0.13 | 0.12 | 0.12 | 0.11 | 0.11 | ASTM D 4751 | ||

Apparent Opening Size O90 | mm ≤ | 0.12 | 0.11 | 0.11 | 0.1 | 0.1 | |||

Physical Identification Properties | |||||||||

Thickness 2KPa | mm | 1.1 | 1.3 | 1.8 | 2.5 | 2.9 | ASTM D 5199 | ||

Mass per unit area | g/m² | 100 | 150 | 200 | 250 | 300 | ASTM D 5261 | ||

Width | m | 2/3/6/ | 2/3/6/ | 2/3/6/ | 2/3/6/ | 2/3/6/ | |||

Pond Liner and Geomembrane Lining Systems - Once known as "flexible membrane liners", geomembranes encompass a broad group of products with distinctive properties and advantages in a multitude of uses as liners for pond lining, landfills, waste water ponds, floating covers, tanks, leach pads, reservoirs, lagoons, barriers, caps, secondary containment - application use is bounded only by the imagination.

What are Geomembranes and Geosynthetics? - Geosynthetics is a general classification representing all man-made materials used in geotechnical engineering applications including pond liners and lake lining. Many of its products are engineered to meet specific design requirements in fluid barrier systems or are designed to enhance the properties of existing soils (physical, hydraulic or mechanical).

Geosynthetics are a Smart Alternative - The value of these products lies in their ability to partially or completely replace [non-renewing] natural resources such as gravel, sand, bentonite clay and do so at a much lower cost. The technical advantages of geosynthetics are the engineered, testable, quality monitored properties of geosynthetic products versus the often difficult to verify quality and specs of naturally occurring materials. Different geosynthetic materials can be combined in order to perform desired functions, often yielding higher "rates" than the components taken separately.

- Q: Geotextile Commission test how many square meters

- 1-2 square meters, I am specializing in the production of geotechnical materials

- Q: Can geotextiles be used in agriculture?

- Yes, geotextiles can be used in agriculture. Geotextiles are commonly employed in agricultural practices for erosion control, soil stabilization, weed suppression, and moisture retention. These fabrics help to improve soil quality, conserve water, and protect crops from adverse weather conditions.

- Q: Geotextile geotextile geotextile construction geotextile specific application

- Geotextile is a large number of textile materials used in civil engineering in recent years, geotextile, with excellent isolation, filtration, drainage, reinforcement, protection, closed and other functions. Geotextile, is widely used in highways, railway subgrade, airport runway, river bed, dam construction and reclamation, flood control and other major projects. Geotextile use: water conservancy construction: seawall, river embankment, lake embankment project; reservoir reinforcement project; beach reclamation project; flood control. Transportation engineering: soft foundation reinforcement treatment; slope protection; drainage system; green isolation zone. Power plant construction: nuclear power plant base, thermal ash dam, hydropower station and other projects. Port waterway works: port terminals, locks, waterway management and other projects. Other works: tunnel, subway, construction, tailings treatment; landfill and other projects

- Q: Can geotextiles withstand harsh weather conditions?

- Yes, geotextiles are designed to withstand harsh weather conditions. They are made from durable materials that are resistant to UV radiation, moisture, and fluctuating temperatures. Geotextiles provide long-lasting protection and stability in various weather conditions, making them suitable for use in challenging environments.

- Q: Geotextile how to set quota

- Geotextile, also known as geotextile, it is made of synthetic fibers through the needle or woven from the permeability of geosynthetics. Finished cloth for the cloth, the general width of 4-6 meters, the length of 50-100 meters. With excellent filtration, isolation, reinforcement protection, high tensile strength, good permeability, high temperature, anti-freeze, anti-aging, corrosion resistance. Borrow the municipal or highway quota corresponding sub-head, according to the actual adjustment of the price, or directly hit b: 001 input price (the price is included in the artificial materials machinery) geotextile, also known as geotextile, it is by the synthetic fiber through the needle Thorn or woven from the permeability of geosynthetics, the physical structure of multi-layer film. Finished cloth for the cloth, the general width of 4-6 meters, the length of 50-100 meters. Geotextile is divided into a woven geotextile and non-woven geotextile. Geotextile has excellent filtration, drainage, isolation, reinforcement, anti-seepage, protection, with light weight, high tensile strength, good permeability, high temperature, anti-freeze, anti-aging, corrosion resistance. The set of quotas is a technical term in the project budget. In the project budget, the budget is the basic principle: to calculate the amount of engineering, and then multiplied by the price, and ultimately draw the total cost of the project, the total cost

- Q: Reinforced geotextiles and composite soil is not the same

- Reinforced geotextile is from its use up, played a role in reinforcement, called reinforced geotextile. Composite geotextile refers to the process, is woven and non-woven acupuncture geotextile, through the acupuncture together with the geotextile. In other words, the ordinary non-woven acupuncture geotextile and composite geotextile in the use of if it is used to reinforced, can be called reinforced geotextile. Huazhi geotextile material manufacturers

- Q: What are the installation techniques for geotextiles?

- There are several installation techniques for geotextiles, depending on the specific application. Common techniques include anchoring the geotextile with pins or stakes, using mechanical or adhesive methods to secure overlapping sections, and incorporating it into the soil through tilling or mixing. The choice of installation technique will depend on factors such as the intended function of the geotextile, the site conditions, and the desired longevity of the installation.

- Q: Can the geotextile function be a filter?

- The role of geotextile can do water filtration.

- Q: How do geotextiles contribute to soil compaction control?

- Geotextiles contribute to soil compaction control by acting as a barrier between the soil and any applied loads or stresses. These textiles distribute the load more evenly, reducing the pressure on the soil and minimizing the potential for compaction. Additionally, geotextiles can improve soil stability and prevent erosion, further aiding in the control of soil compaction.

- Q: Can geotextiles be used in underground pipe installation?

- Yes, geotextiles can be used in underground pipe installation. Geotextiles are often used as a protective layer to prevent the infiltration of fine particles into the pipe system, providing filtration and separation functions. They help to enhance the overall performance and longevity of the pipe installation by reducing soil erosion, promoting drainage, and preventing clogging.

Send your message to us

Geotextile Gazon for Construction - Geosynthetics

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 1500000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords