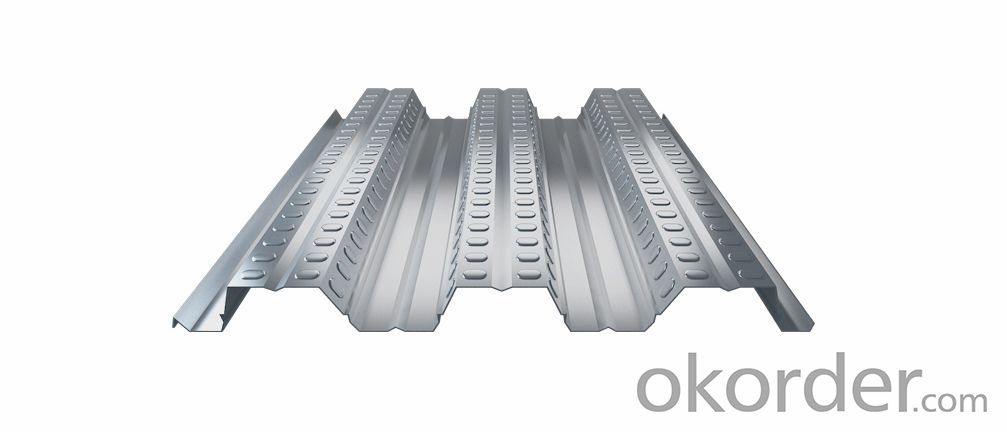

Galvanised Steel Floor Board Decking Sheet

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

Specifications of corrogate sheets :

1) Capacity: about 15,000 tons per month for sheet product.

2) Standard: JIS G3302 1998, ASTM A653M/A924M 2004, all according to the customer's request

3) Thickness: 0.13mm-0.5mm

4) Width: 400mm-1000mm

5) Length: We can adjust the length according to your request

6) Zinc Coating Weight: 60g/m2-275g/m2

7) Raw Materials: Galvanized steel sheet and Pre-painted galvanized steel sheet

8) Spangle: Regular spangle, minimized spangle and zero spangle

9) Hardness: Full hard, normal

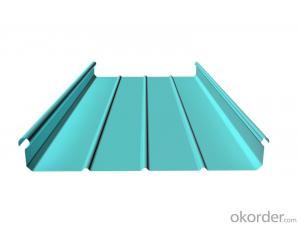

10) Color: RAL, or other series

11) Surface Protection: PE, PVC, PVDF, SMP, HDP, etc.

12) Min trial order 10 tons each thickness, 1x20' per delivery

Specification of corrogate sheets :

1) Chemical Composition: 55% Aluminum, 43.4% Zinc, 1.6% Silicon

2) Substrate: Galvalume steel sheet & Pre-painted galvalume steel sheet

3) Standard: JIS3321/ASTM A792M.

4) Thickness: 0.16mm-2.0mm, all available

5) Width: 600mm-1250mm, all available

6) Aluminum Coating: AZ50/AZ100/AZ150/AZ185

7) Spangle: regular spangle, minimized spangle, zero spangle

8) Surface treatment: Chemical treatment, oil, dry, anti-finger print

9) Color series: RMP/SMP/HDP/PVF2

10) Min trial order: 10 ton each thickness, 1x20' per delivery

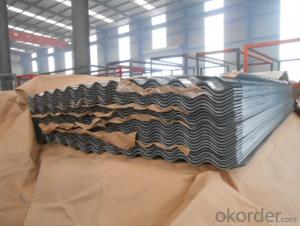

Our Production Facility of corrogate sheets :

After we get the Galvanized sheet, Galvalume sheet, or Pre-painted Sheet, our Roof Panel Forming Machine can manufacture them as Corrugated Galvalume Roofing Sheet.

- Q: Are steel sheets available in different hardness levels?

- Yes, steel sheets are available in different hardness levels. The hardness of a steel sheet is determined by factors such as the composition of the steel, the heat treatment it undergoes, and any additional processing or alloying. Steel sheets can range from very soft and malleable to extremely hard and durable. The most commonly used hardness scale for steel sheets is the Rockwell scale, which measures the indentation hardness of the material. By offering different hardness levels, steel sheets can meet a wide range of application requirements, from forming and bending to high-wear applications that require excellent resistance to abrasion.

- Q: What are the dimensions of the steel sheets?

- Depending on specific requirements or intended use, the dimensions of the steel sheets may differ. Standard sizes for steel sheets are often found in dimensions like 4 feet by 8 feet or 1 meter by 2 meters. Nonetheless, customizing the dimensions of the sheets is also possible to cater to project needs. To ensure the steel sheets meet the required specifications, it is crucial to specify the desired length, width, and thickness when placing an order.

- Q: What is the maximum size available for steel sheets?

- The maximum size available for steel sheets can vary depending on the manufacturer and specific requirements, but commonly available sizes range from 4 feet by 8 feet (1.2 meters by 2.4 meters) to 6 feet by 20 feet (1.8 meters by 6.1 meters).

- Q: Can steel sheets be used for artistic or sculptural projects?

- Yes, steel sheets can be used for artistic or sculptural projects. Steel sheets offer durability, strength, and versatility, making them a popular choice for artists and sculptors. They can be cut, shaped, welded, and manipulated to create various forms and designs, allowing artists to unleash their creativity and bring their visions to life. Additionally, steel sheets can be finished with different coatings or patinas to enhance their aesthetic appeal and protect them from corrosion.

- Q: How are steel sheets inspected for defects?

- To ensure the quality and reliability of steel sheets, various techniques and methods are utilized for defect inspection. One such method involves trained inspectors conducting visual inspections, carefully examining the surface of the steel sheet for visible defects such as cracks, scratches, dents, or irregularities. This examination takes place under appropriate lighting conditions to optimize visibility. Another technique employed is magnetic particle inspection, primarily used for detecting surface or near-surface defects in ferromagnetic materials like steel. By applying a magnetic field to the steel sheet and subsequently introducing iron particles onto the surface, any defects present will attract these particles, forming visible indications. This allows inspectors to pinpoint the location and size of the defect. Ultrasonic inspection, on the other hand, utilizes high-frequency sound waves to identify internal defects within steel sheets. By passing ultrasonic waves through the material and utilizing sensors to detect any alterations in wave patterns caused by defects, this non-destructive testing method can identify imperfections such as voids, cracks, or inclusions that may not be discernible to the naked eye. Additional techniques employed for defect detection in steel sheets include eddy current testing, where electrical currents are induced in the material to identify surface defects, and X-ray inspection, which employs high-energy X-rays to reveal any internal flaws. In summary, a combination of visual inspection and non-destructive testing methods is utilized to conduct thorough defect inspections on steel sheets. This ensures that only high-quality sheets are utilized in various industries, including construction, automotive, and manufacturing.

- Q: What is the average cost of steel sheets compared to fiberglass?

- The average cost of steel sheets compared to fiberglass can vary depending on various factors. Generally, steel sheets tend to be more expensive than fiberglass sheets. This is mainly due to the higher cost of raw materials and the manufacturing process involved in producing steel sheets. Additionally, steel sheets are known for their durability and strength, making them a popular choice for applications where strength and resistance to impact or harsh weather conditions are required. On the other hand, fiberglass sheets are typically less expensive due to the lower cost of raw materials and the simpler manufacturing process. Fiberglass sheets are commonly used in applications where weight and corrosion resistance are important factors, such as in the construction of boats or aircraft. However, it is important to note that the cost of steel sheets compared to fiberglass can also be influenced by market fluctuations, availability, and specific requirements of the project. Therefore, it is recommended to obtain quotes and compare prices from suppliers to get an accurate understanding of the average cost in a given context.

- Q: Can steel sheets be used for automotive body repair?

- Yes, steel sheets can be used for automotive body repair. Steel is a commonly used material in the automotive industry due to its strength, durability, and ability to withstand impacts. Steel sheets can be shaped, welded, and painted to match the original bodywork, making them suitable for repairing dents, rust, and other damages on automotive bodies.

- Q: Can steel sheets be perforated or embossed?

- Yes, steel sheets can be perforated or embossed.

- Q: How much is a steel sheet per square meter?

- The influence of steel prices, in addition to material related, but also with the thickness of the steel plate, thin steel plate prices will be more expensive

- Q: How do steel sheets perform in terms of scratch resistance?

- Renowned for their exceptional ability to resist scratches, steel sheets are widely recognized for their strong and durable nature. This quality makes them highly suitable for a multitude of applications where they may come into contact with objects or surfaces that could potentially cause damage. Moreover, steel sheets possess the capacity to endure regular wear and tear, rendering them particularly suitable for demanding environments with heavy usage. Furthermore, the scratch resistance of steel sheets can be further enhanced by applying coatings or finishes, thereby achieving an even higher level of protection. In summary, the outstanding scratch resistance of steel sheets has earned them a well-deserved reputation as a reliable choice for a diverse range of industrial and commercial purposes.

Send your message to us

Galvanised Steel Floor Board Decking Sheet

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords