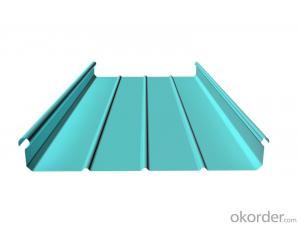

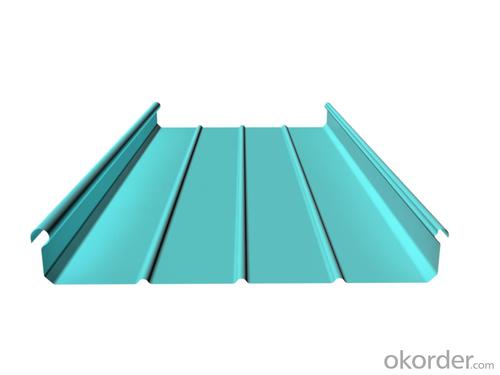

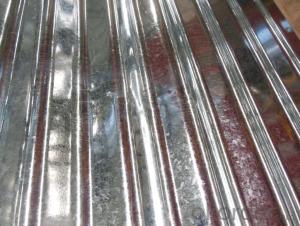

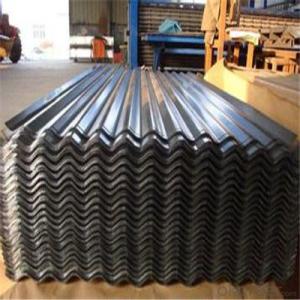

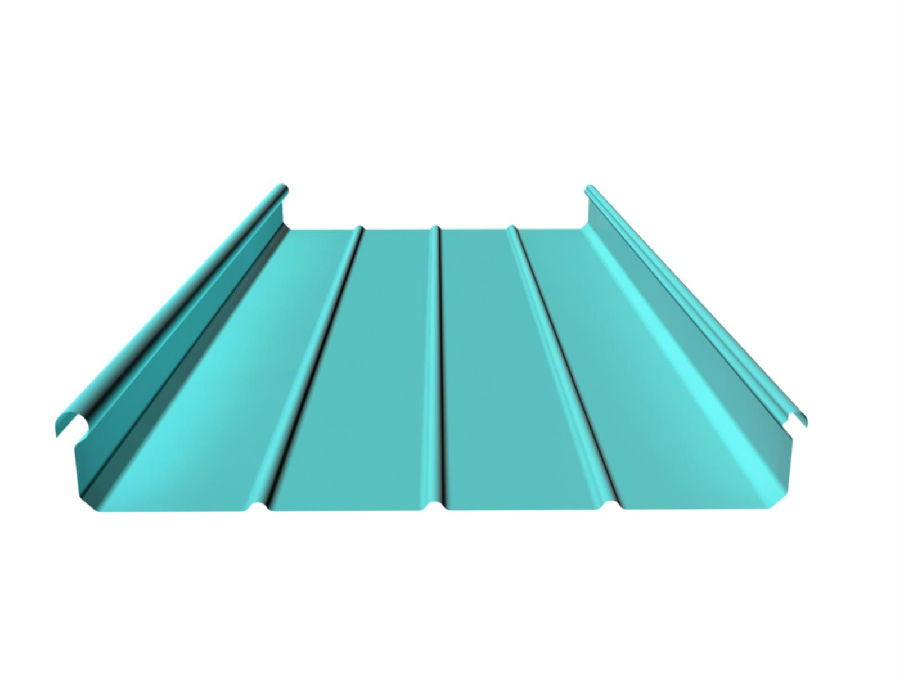

Galvanized Color steel Plate roofing Corrugated

- Loading Port:

- Nanjing

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 4000 PCS

- Supply Capability:

- 38000 PCS/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Galvanized Color steel Plate roofing Corrugated Details

Standard: | AISI,ASTM,BS,DIN,GB | Grade: | Q235,Q345,Q195 |

Technique: | Cold Rolled | Color: | many color |

Thickness: | 0.8mm-4mm,0.3mm-1mm | Surface Treatment: | Coated |

Width: | 600mm-1250mm | Length: | as oer customer's requirement |

experience: | more tahn 8 years | Thickness tolerance: | as per standard |

Type: | Steel Plate |

Packaging & Delivery

Packaging Detail: | Standard Export Package |

Delivery Detail: | 15-30 working days after receive the deposit |

Galvanized Color steel Plate roofing Corrugated Specifications

Corrugated steel sheet

Prompt Delivery

Flexible Payment Terms

Market:Middle East,Asia

Galvanized Color steel Plate roofing Corrugated Services

Our samples can be offerd with sample charged and curier fee by buyer's side

we have full stock, and deivery in short time, many styles with your choices

Good quality+factory price +Quick pesponse +Relablie service, is what we are best trying with you.

All of the products produce by our professionl workman and we have our high-work- effect foreign trde team, you kan totally believe our service.

After you choose, we will count chepest shipping cost and make invoie to you.

Check quality again, and send out to you 1-2 working days after your payment.

Galvanized Color steel Plate roofing Corrugated Pictures

- Q: Are the steel sheets resistant to UV radiation?

- Yes, steel sheets are generally resistant to UV radiation. Steel is a highly durable material that can withstand exposure to various environmental factors, including UV radiation. However, the extent of resistance may vary depending on the specific type of steel and its protective coating. Steel sheets with a high-quality protective coating, such as galvanized or stainless steel, are more resistant to UV radiation compared to bare steel. These coatings act as a barrier, preventing UV rays from directly impacting the steel surface and reducing the likelihood of degradation or discoloration. Additionally, regular maintenance and proper care can further enhance the steel sheets' resistance to UV radiation, ensuring their long-term durability and performance.

- Q: What is the average thickness tolerance for steel sheets?

- The specific grade and manufacturing process can cause the average thickness tolerance of steel sheets to vary. Nonetheless, the industry standard for cold-rolled steel sheets is typically ±0.005 inches (0.13 mm) for sheets up to 36 inches wide, and ±0.010 inches (0.25 mm) for sheets wider than 36 inches. In the case of hot-rolled steel sheets, the average tolerance is usually higher and ranges from ±0.010 inches to ±0.060 inches (0.25 mm to 1.52 mm) depending on the sheet's thickness and width. It is worth noting that these values are averages, and manufacturers may establish their own tolerances based on customer demands and production capabilities.

- Q: Can steel sheets be formed into curved shapes?

- Yes, steel sheets can be formed into curved shapes through various processes such as bending, rolling, or forming.

- Q: Are the steel sheets resistant to UV radiation?

- Yes, steel sheets are generally resistant to UV radiation. Steel is a highly durable material that can withstand exposure to various environmental factors, including UV radiation. However, the extent of resistance may vary depending on the specific type of steel and its protective coating. Steel sheets with a high-quality protective coating, such as galvanized or stainless steel, are more resistant to UV radiation compared to bare steel. These coatings act as a barrier, preventing UV rays from directly impacting the steel surface and reducing the likelihood of degradation or discoloration. Additionally, regular maintenance and proper care can further enhance the steel sheets' resistance to UV radiation, ensuring their long-term durability and performance.

- Q: Can the steel sheets be painted or coated?

- Indeed, it is possible to paint or coat steel sheets. Diverse industries often engage in the practice of painting or coating steel sheets to enhance visual appeal, guard against corrosion, and bolster durability. Prior to any application of paint or coating, it is crucial to thoroughly cleanse and prepare the steel surface to ensure proper adhesion. The choice of paint or coating depends on the desired finish, environmental conditions, and specific application. It is imperative to select a paint or coating that is compatible with the steel substrate and capable of enduring the intended use and exposure to chemicals, moisture, UV radiation, or other factors that may impact the performance and lifespan of the coating.

- Q: How do steel sheets perform in UV resistance?

- Steel sheets do not have inherent UV resistance. However, the addition of protective coatings or treatments can significantly improve their ability to resist damage from UV radiation.

- Q: What is the electrical resistivity of steel sheets?

- The electrical resistivity of steel sheets typically ranges from 10^-6 to 10^-7 ohm-meters.

- Q: How do I print the steel plate?

- It's not print. It was corrosion first. It's laser engraving. Now it's 20 watts above the laser to carve the metal

- Q: What are the common thicknesses for hot-rolled steel sheets?

- The common thicknesses for hot-rolled steel sheets range from 1.5mm to 20mm, with popular options including 3mm, 6mm, 8mm, and 10mm.

- Q: What are the benefits of using pre-painted steel sheets?

- There are several benefits of using pre-painted steel sheets. Firstly, they offer a wide range of colors and finishes, allowing for greater design flexibility. Secondly, pre-painted steel sheets are highly resistant to corrosion, providing long-lasting durability. Additionally, they require minimal maintenance, as the paint coating acts as a protective layer against damage and weathering. Furthermore, pre-painted steel sheets are easy to install and can be used in various applications, including roofing, siding, and construction. Overall, their aesthetic appeal, durability, and low maintenance requirements make them a preferred choice in many industries.

Send your message to us

Galvanized Color steel Plate roofing Corrugated

- Loading Port:

- Nanjing

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 4000 PCS

- Supply Capability:

- 38000 PCS/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords