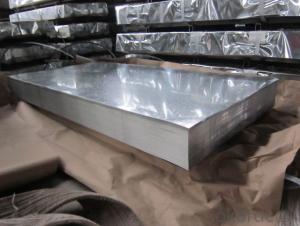

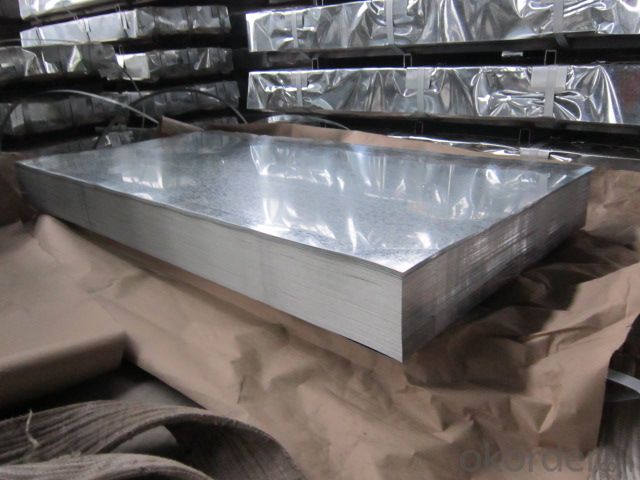

Galvanized Steel Sheet Export on OKorder.com

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 m.t

- Supply Capability:

- 300 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Galvanized Steel Sheet raw steel material from Big Mill with reliable quality.

Construction, packaging, railway vehicles, agricultural machinery and daily life.

Oiled/dry, Skin-pass/Nonskin-pass, Regular/Minimize/Zero Spangle

Application: with excellent cold bending molded manufacturablity, good decoration effect, strong anti-corrosion ability, galvanized steel coils and sheets are also pollution-free and easily recycled. Accordingly, they can be used as final products and basic plates of color coated steel coils and widely applied in construction, home appliances, decoration, ect.

CORRUGATED GALVANIZED STEEL SHEETS

Base sheet : galvanized steel sheet, pre painted galvanized steel sheet

Zinc:40G-275G

Thickness:0.12mm-3.2mm

Width:600mm-1500mm

Length:1000mm-11800mm or as request

Package:Standard seaworthy export packing: 3 layers of packing, inside is

kraft paper,water plastic film is in the middle and outside GI steel

sheet to be covered by steel strips with lock.

After the chemical reaction between aluminum and oxygen in the air, A layer of strong and dense oxide film will be generated. This layer of aluminum oxide film preservation became "coat", the internal aluminum is difficult for them to oxygen in the air to oxidation, so aluminum is placed in the atmosphere a year, which is less than the depth of corrosion of thousands of hours one millimeter. If the same time into the aluminum and steel containing 3% of sodium chloride and 1% of the hydrogen chloride in the container, the corrosion test of 70 hours, the average weight loss of steel per square centimeter 11.07 mg in weight loss of aluminum average of 0.675 milligrams per square centimeter, which proves the corrosion resistance of aluminum is generally much higher than the steel. However, the natural oxide film of aluminum, there are still shortcomings thin and soft, corrosion is not very strong, so that the service life of corrugated sheet aluminum untreated generally only about 20 years. If aluminum by chemical oxidation (i.e., at a certain temperature of the aluminum oxide surface cleaning and liquid oxygen in a chemical reaction) or electrochemical oxidation (i.e. the aluminum into the electrolyte, in the role of the applied current and oxygen ions the method of a direct reaction of water with aluminum surface cleaning) are processed, on the surface of the aluminum layer will generate 0.025 to about 0.05 millimeters thick and hard and even more some of the oxide film, so as to further improve the corrosion resistance of aluminum performance. After aluminum corrugated sheets thus treated, the service life of up to 60 years. Aluminum corrugated sheets can also be a variety of bright colors, it is possible to make the building more beautiful.

- Q: Can steel sheets be used for manufacturing shipping pallets?

- Yes, steel sheets can be used for manufacturing shipping pallets. Steel sheets provide durability, strength, and resistance to damage, making them suitable for heavy-duty applications like shipping pallets.

- Q: Are the steel sheets resistant to scratching or abrasion?

- Steel sheets exhibit a remarkable resistance to scratching and abrasion. Renowned for its exceptional durability and strength, steel effectively wards off numerous forms of damage, such as scratches and abrasions. Its sleek and solid surface reduces susceptibility to scratches from sharp objects or rough surfaces. Moreover, the robust molecular structure of steel hampers easy wear and tear, guaranteeing its longevity in high-traffic or demanding settings. All in all, steel sheets prove to be an outstanding option for safeguarding against scratching or abrasion.

- Q: Can steel sheets be used for shipping containers?

- Yes, steel sheets can be used for shipping containers.

- Q: Are steel sheets suitable for swimming pool construction?

- Yes, steel sheets are suitable for swimming pool construction. Steel sheets are known for their strength and durability, making them an excellent choice for building swimming pools. They provide a stable and sturdy structure that can withstand the weight of the water and the pressure exerted on the pool walls. Additionally, steel sheets can be easily molded and welded into various shapes and sizes, allowing for customization and flexibility in pool design. Moreover, steel is resistant to corrosion, which is crucial for maintaining the integrity of the pool over time, especially when exposed to chlorinated water. Therefore, steel sheets are a reliable and popular option for swimming pool construction.

- Q: How much is 2 millimeters per square meter?

- GB two mm steel plate per square weight of about 15.7 kilograms, converted into per square should be 80-100 yuan.Steel plate is made of molten steel, cooled and compressed into flat steel. Steel plate by thickness, thin steel plate <4 mm (thinnest 0.2 mm), thick steel plate 4~60 mm, extra thick steel plate 60~115 mm. The steel plate is divided into hot-rolled and cold-rolled parts by rolling

- Q: What are the different methods of joining steel sheets together?

- There are several methods of joining steel sheets together, including welding, riveting, bolting, and adhesive bonding.

- Q: Can steel sheets be used for industrial machinery?

- Yes, steel sheets can definitely be used for industrial machinery. Steel is a widely used material in the manufacturing industry due to its exceptional strength, durability, and versatility. Steel sheets can be formed, machined, and welded into various shapes and sizes to meet the specific requirements of industrial machinery. Additionally, steel sheets offer excellent resistance to corrosion, impact, and extreme temperatures, making them ideal for heavy-duty applications. The use of steel sheets in industrial machinery ensures structural integrity, longevity, and enhanced performance, making it a preferred choice for many manufacturers in the industry.

- Q: How do steel sheets perform in terms of electrical resistance?

- Steel sheets are generally poor conductors of electricity due to their high electrical resistance.

- Q: What is the process of cutting steel sheets?

- The process of cutting steel sheets typically involves using specialized machines or tools, such as plasma cutters, lasers, or shears, to cut through the steel material. The method chosen depends on factors like the thickness of the steel, desired precision, and production volume. These tools apply heat, force, or a combination of both to remove material and create a clean, precise cut in the steel sheets.

- Q: What is the difference between a painted and laminated steel sheet?

- A painted steel sheet is coated with a layer of paint, while a laminated steel sheet has a layer of plastic or other material laminated onto the surface. This makes laminated steel sheets more resistant to scratches and damage, while painted steel sheets offer a wider range of color options.

Send your message to us

Galvanized Steel Sheet Export on OKorder.com

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 m.t

- Supply Capability:

- 300 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords