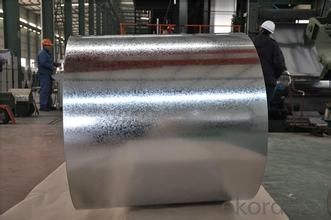

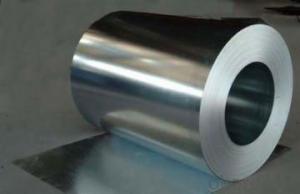

excellent hot-dip galvanized/ aluzinc steel sheet in good quality

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 5000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description:

1.Mateials:SGCC,DX51D / DX52D /S250,280GD

2.Size:width:600-1250mm(900mm,1215mm,1250mm,1000mm the most common)

thickness:0.15-2.0mm

length:1000-6000mm,as your require

3.Zinc coating :60-180g( as required)

4.Coil id:508mm

5.Coil weight: 3-5MT(as required)

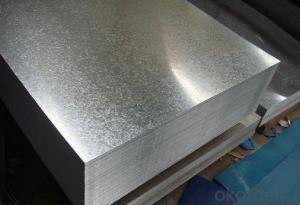

6. Surface:regular/mini/zero spangle, chromated, skin pass, dry etc.

Applications of our Galvalume Coil:

Galvalume Coil widely used for roofing products, It is also the ideal base material for Prepainted Steel Coil.

1. roofing

2. gutters

3. unexposed automotive parts

4. appliances

5. furniture

6. outdoor cabinetry

Production of cold formed corrugated sheets and profiles for roofing, cladding, decking, tiles, sandwich walls, rainwater protective systems, air conditioning duct as well as electrical appliances and engineering.

We can ensure that stable quality standards are maintained, strictly meeting both market requirements and customers’ expectations. Our products enjoy an excellent reputation and have been exported to Europe, South-America, the Middle-East, Southeast-Asia, Africa and Russia etc.. We sincerely hope to establish good and long-term business relationship with your esteemed company.

- Q: Can steel sheets be used for fencing or security purposes?

- Yes, steel sheets can be used for fencing or security purposes. Steel sheets are durable and sturdy, making them an excellent material for constructing fences and barriers that provide enhanced security and protection. Their strength and resistance to wear and tear make them suitable for withstanding various external factors and potential intrusions. Additionally, steel sheets can be customized to fit different designs and sizes, ensuring they meet specific fencing or security requirements.

- Q: What is the process of applying anti-fingerprint coatings to steel sheets?

- The process of applying anti-fingerprint coatings to steel sheets typically involves several steps. First, the steel sheets are thoroughly cleaned and degreased to remove any dirt or oil residue. This step is crucial to ensure proper adhesion of the coating. Next, a primer or base coat is applied to the steel sheets. This coat helps improve the bonding between the steel surface and the subsequent layers of the coating. After the base coat, the anti-fingerprint coating is applied using various methods such as spraying, dipping, or roll coating. This coating is designed to repel oils and fingerprints, making the steel sheets easier to clean and maintain. Once the coating is applied, the steel sheets are cured or dried according to the manufacturer's instructions. This step is important to ensure the coating fully adheres to the steel surface and develops its desired properties. Overall, the process of applying anti-fingerprint coatings to steel sheets involves cleaning, priming, coating, and curing to achieve a durable and effective solution for reducing fingerprints and smudges.

- Q: Can the steel sheets be used as a magnetic surface?

- Indeed, the use of steel sheets as a magnetic surface is possible. Steel, being a ferromagnetic material, possesses the ability to be magnetized and maintain its magnetism even when the magnet is no longer present. This characteristic enables steel sheets to attract and secure magnetic items. In numerous scenarios, steel sheets are widely employed as magnetic surfaces, including magnetic boards, magnetic whiteboards, and magnetic organizers. By employing magnets, it becomes effortless to affix notes, documents, and additional magnetic objects onto steel sheets, rendering them a practical and adaptable means of organization and exhibition.

- Q: Are steel sheets suitable for outdoor applications?

- Yes, steel sheets are suitable for outdoor applications. Steel is highly durable, weather-resistant, and can withstand harsh environmental conditions, making it an excellent choice for outdoor usage.

- Q: How are steel sheets packaged for shipping?

- Typically, steel sheets are packaged in a manner that guarantees their protection during transportation. This is achieved through a series of steps aimed at preventing any damage or deformation that may occur during transit. To start, the steel sheets are commonly stacked on wooden pallets or placed in sturdy steel crates. This serves to create a stable base and prevents any movement or shifting of the sheets during transportation. Additionally, the use of pallets or crates facilitates the loading and unloading of the sheets onto trucks or containers. To further safeguard the steel sheets from scratches or other forms of surface damage, they are often wrapped with a layer of protective material. This can include plastic wraps, paper or cardboard interleaves, or even an application of oil or rust inhibitor. These protective materials act as a barrier, preventing any direct contact that could potentially cause scratches. Furthermore, steel sheets may be securely bundled together using steel strapping or wire. This bundling process helps to maintain the structural integrity of the sheets and prevents them from shifting or sliding during transportation. Lastly, once the steel sheets are appropriately packaged, they are typically labeled with pertinent information such as product specifications, quantity, and destination. This ensures ease of identification and proper handling at each stage of the shipping process. In summary, the packaging of steel sheets for shipping is meticulously carried out to ensure their safe and secure transportation. By utilizing pallets or crates, protective materials, bundling, and labeling, steel sheets can withstand the demands of shipping and reach their destination in optimal condition.

- Q: Are the steel sheets resistant to impact or denting?

- Yes, steel sheets are generally resistant to impact and denting due to their high strength and durability.

- Q: Do steel sheets require any surface treatment before installation?

- Yes, steel sheets generally require surface treatment before installation to prevent corrosion, improve paint adhesion, and enhance their overall durability and longevity. Common surface treatments include cleaning, degreasing, priming, and applying protective coatings such as galvanizing or powder coating.

- Q: Are steel sheets suitable for oil rig platforms?

- Oil rig platforms benefit greatly from the use of steel sheets. The reason for this lies in the exceptional strength and durability of steel, which makes it a popular choice in their construction. Given the harsh environmental conditions that oil rig platforms face, such as extreme temperatures, high winds, and corrosive saltwater, steel has proven itself capable of withstanding these challenges effectively. Steel sheets offer a solid and dependable base for oil rig platforms. They ensure that the platforms can bear the weight of the rig, equipment, and personnel without compromising stability or safety. The high strength of steel allows for the construction of large and intricate structures without sacrificing stability. Moreover, steel exhibits remarkable resistance to corrosion, making it an ideal material for offshore applications. Oil rig platforms are constantly exposed to saltwater, which can cause corrosion and weaken other materials. However, steel sheets can be treated with protective coatings to enhance their resistance to corrosion and extend their lifespan. In addition to its strength and corrosion resistance, steel is a versatile material that lends itself to easy shaping and fabrication. This versatility allows for efficient and cost-effective construction processes, reducing the time and resources required for installation and maintenance. In conclusion, steel sheets are a suitable choice for oil rig platforms due to their strength, durability, corrosion resistance, and versatility. They provide a reliable and robust foundation for offshore drilling operations, ensuring the safety and longevity of the platform in challenging environments.

- Q: Are the steel sheets available in different thickness tolerances?

- Certainly, there are various thickness tolerances for steel sheets that are readily available. Steel producers create sheets with diverse thicknesses to accommodate different purposes and demands. These tolerances are determined by established standards within the industry and can differ based on the steel type and intended application. In construction, for instance, tighter tolerances might be mandatory to guarantee the structural soundness, while in manufacturing sectors like automotive or aerospace, precise tolerances may be indispensable to meet design requirements. Through offering steel sheets in varying thickness tolerances, manufacturers allow customers to select the most fitting product for their individual requirements.

- Q: Can steel sheets be used for agricultural equipment?

- Yes, steel sheets can be used for agricultural equipment. Steel is a durable and strong material that can withstand the harsh conditions and heavy use associated with agricultural activities. It is commonly used in the construction of farming equipment such as plows, harrows, and seeders. Steel sheets can also be shaped and welded into various forms to meet specific agricultural needs.

Send your message to us

excellent hot-dip galvanized/ aluzinc steel sheet in good quality

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 5000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords